Method for replacing carbon neutralization with building material industrial fuel

A carbon neutralization and industrial technology, applied in the field of carbon neutralization methods in the building materials industry, can solve the problems of large diffusion coefficient, poor hydrogen flame stability, flammable and explosive hydrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific examples.

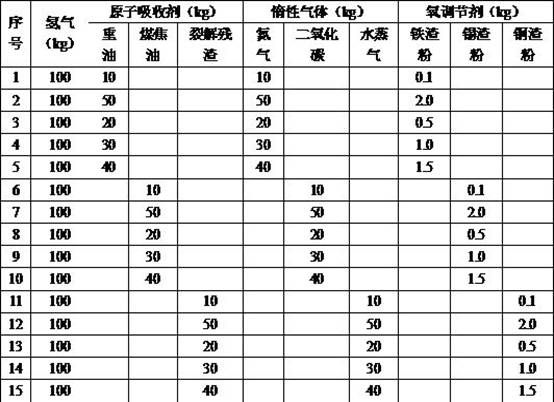

[0024] Put hydrogen, atomic absorbent, inert gas, oxygen regulator, and modified flame retardant into the burner, spray them out from different channels of the burner, and mix and burn outside the burner nozzle to obtain stable and adjustable length flame; wherein, the modified flame retardant is obtained by uniformly mixing the flame retardant and the surfactant. The formula of hydrogen, atomic absorbent, inert gas and oxygen regulator is shown in Table 1, and the formula of flame retardant and surfactant in the modified flame retardant, the length and temperature of the flame are shown in Table 2.

[0025] Table 1

[0026]

[0027] Table 2

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com