Carbon rod heating non-combustion tobacco product

A heat-not-burn and tobacco product technology, applied in the fields of tobacco, smoker’s products, cigars, etc., can solve the problem of incomplete combustion of combustion smoke, rapid combustion of flammable carbon particles, oxygen consumption, and combustion of difficult-to-combustible carbon particles for oxygen supply Insufficient and other problems, to achieve the effect of increasing temperature and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

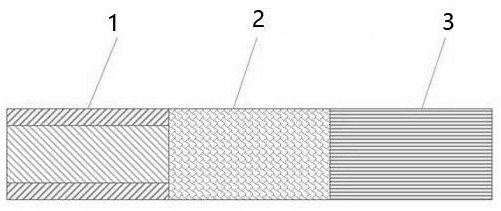

[0034] A carbon rod heat-not-burn tobacco product comprises a fuel section 1, a combustion smoke purification section 2, and a smoking smoke generation section 3 connected in sequence.

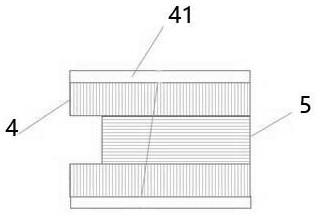

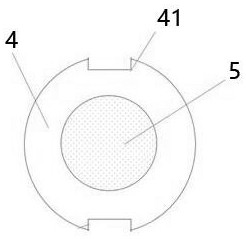

[0035] The fuel section 1 is provided with a coaxial first carbon rod 4 and a second carbon rod 5, the first carbon rod 4 and the second carbon rod 5 form a carbon heat source in the form of a double-layer carbon rod, the first carbon rod 4 and the second carbon rod 5 The ignition point and burning resistance of the second carbon rod 5 are significantly different. The ignition point of the first carbon rod 4 is 150°C, and the burnout temperature of the first carbon rod 4 is 600°C, which is regarded as a flammable carbon rod. The ignition point of the second carbon rod 5 is 300°C, the burnout temperature of the second carbon rod 5 is less than or equal to 850°C, and it is regarded as a flame-retardant carbon rod, the first carbon rod 4 is chrysanthemum charcoal, and the first carbon rod 5 The c...

Embodiment 2

[0041] A carbon rod heat-not-burn tobacco product comprises a fuel section 1, a combustion smoke purification section 2, and a smoking smoke generation section 3 connected in sequence.

[0042] The fuel section 1 is provided with a coaxial first carbon rod 4 and a second carbon rod 5, the first carbon rod 4 and the second carbon rod 5 form a carbon heat source in the form of a double-layer carbon rod, the first carbon rod 4 and the second carbon rod 5 The ignition point and burning resistance of the second carbon rod 5 are significantly different. The ignition point of the first carbon rod 4 is 350°C, and the burnout temperature of the first carbon rod 4 is 580°C, which is regarded as a flammable carbon rod. The ignition point of the second carbon rod 5 is 600°C, and the burnout temperature of the second carbon rod 5 is 750°C, which is regarded as a flame-retardant carbon rod. The first carbon rod 4 includes a mixture of chrysanthemum charcoal and cotton stalk charcoal, The ca...

Embodiment 3

[0048] A carbon rod heat-not-burn tobacco product comprises a fuel section 1, a combustion smoke purification section 2, and a smoking smoke generation section 3 connected in sequence.

[0049]The fuel section 1 is provided with a coaxial first carbon rod 4 and a second carbon rod 5, the first carbon rod 4 and the second carbon rod 5 form a carbon heat source in the form of a double-layer carbon rod, the first carbon rod 4 and the second carbon rod 5 The ignition point and burning resistance of the second carbon rod 5 are significantly different. The ignition point of the first carbon rod 4 is 300°C, and the burnout temperature of the first carbon rod 4 is 580°C, which is regarded as a flammable carbon rod. The ignition point of the second carbon rod 5 is 450°C, the burnout temperature of the second carbon rod 5 is less than or equal to 750°C, and it is regarded as a flame-retardant carbon rod, and the first carbon rod 4 is a mixture of chrysanthemum charcoal and tobacco charco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com