Substrate scribing and carrying device

A handling device and scribing technology, applied in the directions of transportation and packaging, cleaning methods and utensils, laser welding equipment, etc., can solve the problems of broken ceramic substrates, easy scratches, etc., to avoid messy accumulation, facilitate rapid handling, and facilitate Effects of slag removal and positioning handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

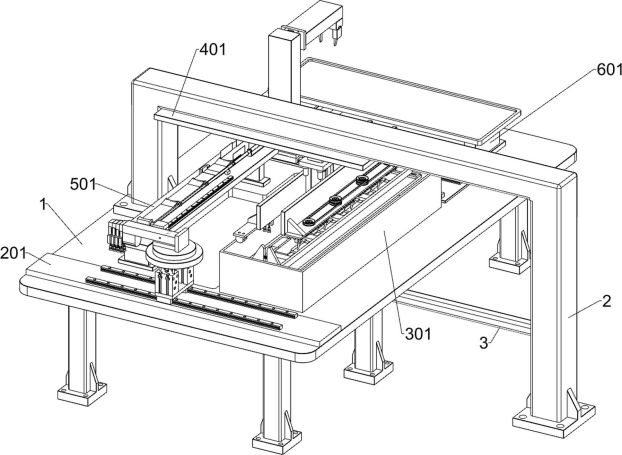

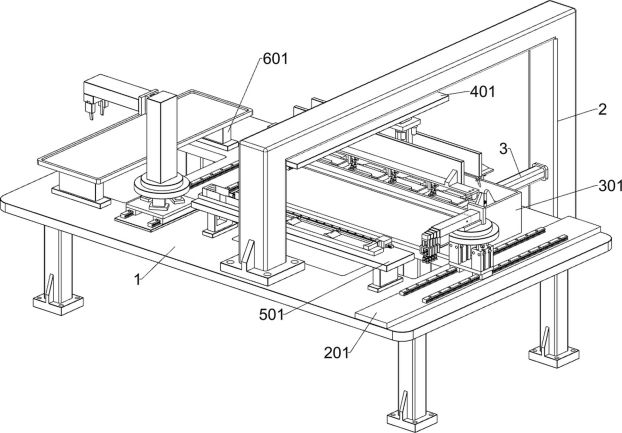

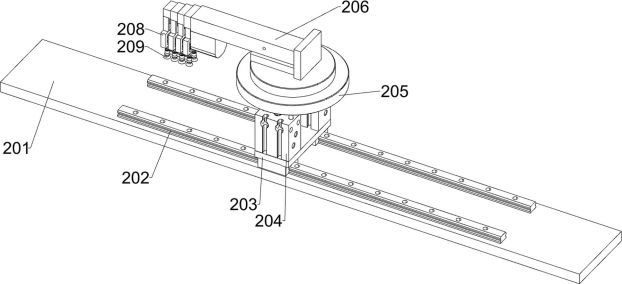

[0036] A substrate scribing and conveying device, such as Figure 1-6 As shown, it includes a frame 1, a gantry 2, a connecting rod 3, a handling system and a clamping system; the left part of the upper side of the frame 1 is bolted to the gantry 2; the right part of the frame 1 is connected to the connecting rod 3 by bolts; The right side of the connecting rod 3 is fixedly connected with the gantry frame 2; the upper front part of the frame 1 is connected with a handling system; the upper right part of the frame 1 is connected with a clamping system.

[0037] When in use, first place the substrate scribing and conveying device at the required position, place the rack 1 on a stable position, first move the conveying system to the right rear side where the laser is ready to cut the oval ceramic substrate, and wait for the laser to cut the ceramic When the substrate is cut in half, the handling system moves to the cut ceramic substrate and holds the ceramic substrate. After the ...

Embodiment 2

[0043] On the basis of Example 1, such as figure 1 with Figure 7-16 As shown, it also includes a slag removal and handling system. The lower side of the gantry 2 is connected with a slag removal and handling system. The slag removal and handling system includes a third mounting plate 401, a second electric slide rail 402, and a second fixing plate 403. , the second electric push rod 404, the first fixed block 405, the fourth mounting plate 406, the fifth mounting plate 407, the slag removal component and the handling component; the gantry frame 2 lower side bolts are connected with the third mounting plate 401; the third A second electric slide rail 402 is connected with each bolt at the lower front part and the lower rear part of the mounting plate 401; the two second electric slide rails 402 are connected with a second fixed plate 403 by slider bolts; the second fixed plate 403 Each of the four corners of the lower side is fixedly connected with a second electric push rod ...

Embodiment 3

[0055] On the basis of Example 2, such as figure 1 with Figure 17-18 As shown, it also includes a stacking system, the upper rear of the frame 1 is connected to the stacking system, and the stacking system also includes a first square base 601, a third placement plate 602, a sixth mounting plate 603, a fourth Electric slide rail 604, fourth fixed plate 605, second square base 606, second electric turntable 607, vertical plate 608, fifth electric slide rail 609, fifth fixed plate 610, horizontal plate 611 and manipulator 612; Rack 1 Two first square bases 601 are fixedly connected to the upper rear part; the third placing board 602 is fixedly connected to the upper side of the two first square bases 601; the sixth mounting board is fixedly connected to the upper rear part of the frame 1 603, the sixth mounting plate 603 is located in front of the first square base 601; each bolt on the upper front and upper rear of the sixth mounting plate 603 is connected with a fourth elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com