Industrial environment-friendly glue and production process thereof

An environmentally friendly glue technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of glue not being environmentally friendly, small molecular weight, and insufficient bonding strength, etc., to reduce the chance of glue deterioration , improved strength, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

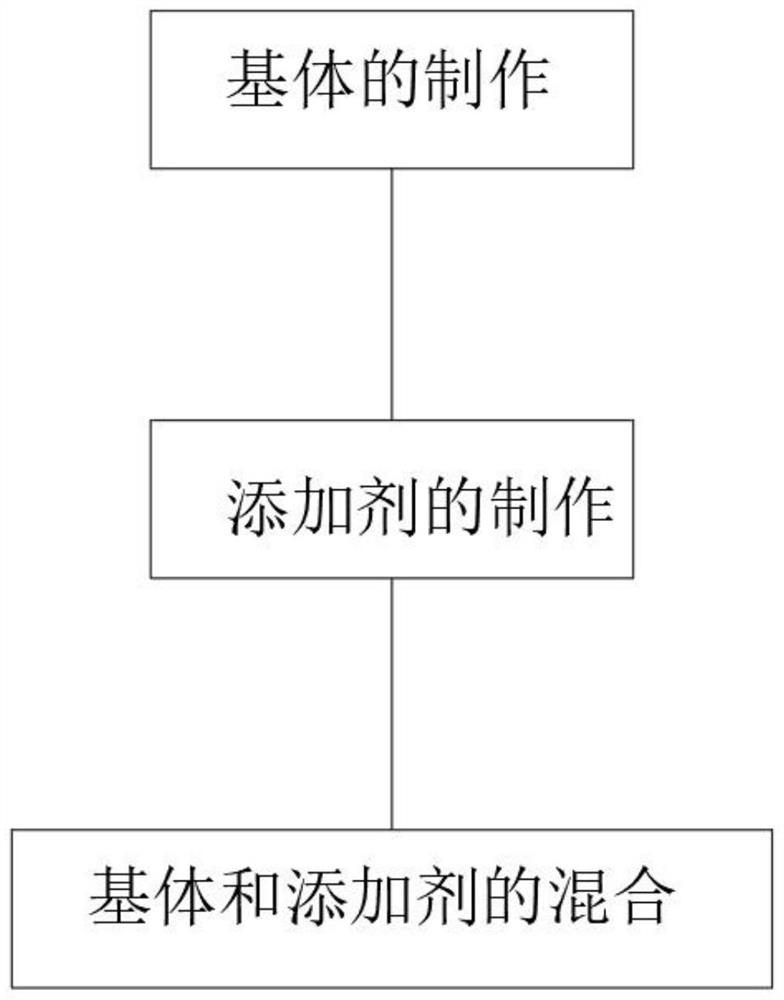

Image

Examples

Embodiment 1

[0022] An industrial environment-friendly glue includes: its raw materials include the following components by weight: 50 parts of ethylene-vinyl acetate copolymer, 5 parts of aluminum hydroxide, 3 parts of methylcycloethane, 1 part of bactericide, 2 parts of butyl rubber 3 parts of epoxy resin, 2 parts of castor oil, 20 parts of terpene resin, 8 parts of acrylamide, 2 parts of barium sulfate, 1 part of ammonium persulfate, and 1 part of nano-sized titanium dioxide.

[0023] The ethylene-vinyl acetate copolymer is chlorinated.

[0024] The production process of industrial environment-friendly glue comprises the following steps:

[0025] a. Fabrication of the matrix: take the chlorinated ethylene-vinyl acetate copolymer and place it in the first reaction kettle, heat it to 92-98°C, and keep it warm for 30-45min;

[0026] b. After the heat preservation is over, add terpene resin, butyl rubber and castor oil successively into the first reaction kettle, stir at high speed for 30-...

Embodiment 2

[0031] An industrial environment-friendly glue includes: its raw materials include the following components by weight: 60 parts of ethylene-vinyl acetate copolymer, 6 parts of aluminum hydroxide, 4 parts of methylcycloethane, 1.5 parts of bactericide, 2.5 parts of butyl rubber 4 parts of epoxy resin, 2.5 parts of castor oil, 25 parts of terpene resin, 9 parts of acrylamide, 2.5 parts of barium sulfate, 1.5 parts of ammonium persulfate, and 1.5 parts of nano-sized titanium dioxide.

[0032] The ethylene-vinyl acetate copolymer is chlorinated.

[0033] The production process of industrial environment-friendly glue comprises the following steps:

[0034] a. Fabrication of the matrix: take the chlorinated ethylene-vinyl acetate copolymer and place it in the first reaction kettle, heat it to 92-98°C, and keep it warm for 30-45min;

[0035] b. After the heat preservation is over, add terpene resin, butyl rubber and castor oil successively into the first reaction kettle, stir at hig...

Embodiment 3

[0040] An industrial environment-friendly glue includes: 65 parts of ethylene-vinyl acetate copolymer, 7 parts of aluminum hydroxide, 5 parts of methylcycloethane, 2 parts of fungicide, 3 parts of butyl rubber, 5 parts of epoxy resin, castor oil 3 parts, 30 parts of terpene resin, 10 parts of acrylamide, 3 parts of barium sulfate, 2 parts of ammonium persulfate, and 2 parts of nano-sized titanium dioxide.

[0041] The ethylene-vinyl acetate copolymer is chlorinated.

[0042] The production process of industrial environment-friendly glue comprises the following steps:

[0043] a. Fabrication of the matrix: take the chlorinated ethylene-vinyl acetate copolymer and place it in the first reaction kettle, heat it to 92-98°C, and keep it warm for 30-45min;

[0044] b. After the heat preservation is over, add terpene resin, butyl rubber and castor oil successively into the first reaction kettle, stir at high speed for 30-50min, and control the rotating speed of the stirring blade at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com