Nano-antibacterial heat dissipation insole material and preparation method thereof

A nanometer and insole technology, applied in the field of material chemistry, can solve problems such as poor antibacterial effect, poor air permeability, and heavy odor, and achieve good antibacterial properties and bactericidal performance, high water absorption, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

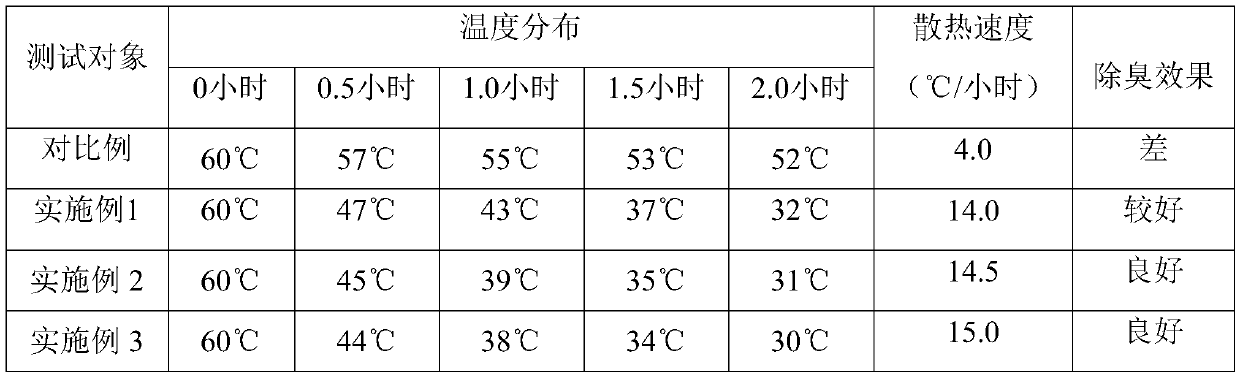

Examples

Embodiment 1

[0056] An antibacterial heat dissipation insole material comprises an antibacterial layer 1, a heat dissipation layer 2, and an elastic shock absorption layer 3. The antibacterial layer 1 is arranged on one side of the heat dissipation layer 2, and the other side of the heat dissipation layer 2 is provided with an elastic shock absorption layer 3.

[0057] 1. Fabric preparation of antibacterial layer 1:

[0058] 1) Add 80 parts of bagasse to 150 parts by volume of deionized water, soak at a temperature of 100° C., cook at high temperature and high pressure for 1 hour, and then dry;

[0059] 2) Put the dried bagasse into a pulverizer and pulverize to 500 mesh bagasse powder;

[0060] 3) Put the obtained sugarcane powder, 20 parts of ethylene glycol and 300 parts by weight of deionized water into a ball mill, perform wet ball milling for 2 hours, filter, and wash the filter residue to obtain pretreated bagasse powder;

[0061] 4) Add 5 parts of 20nm nanometer silver to 500 part...

Embodiment 2

[0074] An antibacterial heat dissipation insole material comprises an antibacterial layer 1, a heat dissipation layer 2, and an elastic shock absorption layer 3. The antibacterial layer 1 is arranged on one side of the heat dissipation layer 2, and the other side of the heat dissipation layer 2 is provided with an elastic shock absorption layer 3.

[0075] 1. Fabric preparation of antibacterial layer 1:

[0076] 1) Add 100 parts of bagasse to 250 parts by weight of deionized water, soak at a temperature of 100° C., cook at high temperature and high pressure for 1.5 hours, and then dry;

[0077] 2) Put the dried bagasse into a pulverizer and pulverize to 700 mesh bagasse powder;

[0078] 3) Put the obtained sugarcane powder, 30 parts of ethylene glycol and 400 parts by weight of deionized water into a ball mill, perform wet ball milling for 2 hours, filter, and wash the filter residue to obtain the pretreated bagasse powder;

[0079] 4) Add 8 parts of 30nm nanometer silver to ...

Embodiment 3

[0092] An antibacterial heat dissipation insole material comprises an antibacterial layer 1, a heat dissipation layer 2, and an elastic shock absorption layer 3. The antibacterial layer 1 is arranged on one side of the heat dissipation layer 2, and the other side of the heat dissipation layer 2 is provided with an elastic shock absorption layer 3.

[0093] 1. Fabric preparation of antibacterial layer 1:

[0094] 1) 120 parts of bagasse were added to 400 parts by weight of deionized water, soaked at a temperature of 100°C, cooked at high temperature and high pressure for 2.0 hours, and then dried;

[0095] 2) Put the dried bagasse into a pulverizer and pulverize to 1000 mesh bagasse powder;

[0096] 3) Put the obtained sugarcane powder, 50 parts of ethylene glycol and 500 parts by weight of deionized water into a ball mill, perform wet ball milling for 2.5 hours, filter, and wash the filter residue to obtain pretreated bagasse powder;

[0097] 4) Add 10 parts of 50nm nanometer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com