High-temperature oxygen-free copper-316L stainless steel layered composite material and preparation process thereof

A -316L, stainless steel layer technology, which is applied in the field of oxygen-free copper-316L stainless steel layered composite materials and preparation technology for high temperature, can solve the problem of copper layer grain size growth, copper and stainless steel delamination, and copper-steel interface delamination and other issues, to achieve good shaping and toughness, low cost, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

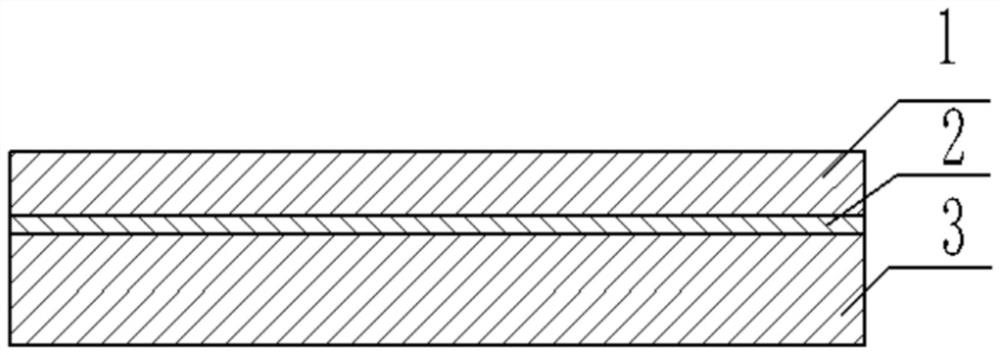

[0026] The present invention proposes an oxygen-free copper-316L stainless steel layered composite material for high temperature. The composite material is a three-layer layered structure, which is oxygen-free copper 1, pure nickel 2 and 316L stainless steel 3 in sequence, with a total thickness of 0.1mm, wherein the oxygen-free The thickness of copper 1 accounts for 25% of the total thickness, the thickness of pure nickel 2 accounts for 0.5% of the total thickness, and the rest is 316 stainless steel 3.

[0027] The present invention also proposes a preparation process for oxygen-free copper-316L stainless steel layered composite material for high temperature, comprising the following steps:

[0028] Step 1: Wash and degrease the surface of an oxygen-free copper strip with a thickness of 1.5mm and a pure nickel strip with a thickness of 0.03mm. The purity of pure nickel is not lower than the N6 standard. Cleaning with organic solvents, pickling and grinding is carried out in ...

Embodiment 2

[0034] The present invention proposes an oxygen-free copper-316L stainless steel layered composite material for high temperature. The composite material is a three-layer layered structure, which is oxygen-free copper 1, pure nickel 2 and 316L stainless steel 3 in sequence, with a total thickness of 0.3mm, wherein the oxygen-free The thickness of copper 1 accounts for 50% of the total thickness, the thickness of pure nickel 2 accounts for 0.5% of the total thickness, and the rest is 316 stainless steel 3.

[0035] The present invention also proposes a preparation process for oxygen-free copper-316L stainless steel layered composite material for high temperature, comprising the following steps:

[0036] Step 1: Wash and degrease the surface of an oxygen-free copper strip with a thickness of 3.0mm and a pure nickel strip with a thickness of 0.06mm. The purity of pure nickel is not lower than the N6 standard. Cleaning with organic solvents, pickling and grinding is carried out in ...

Embodiment 3

[0042] The present invention proposes an oxygen-free copper-316L stainless steel layered composite material for high temperature. The composite material has a three-layer layered structure, which is oxygen-free copper 1, pure nickel 2 and 316L stainless steel 3 in sequence, with a total thickness of 0.5mm, wherein the oxygen-free The thickness of copper 1 accounts for 75% of the total thickness, the thickness of pure nickel 2 accounts for 0.5% of the total thickness, and the rest is 316 stainless steel 3.

[0043] The present invention also proposes a preparation process for oxygen-free copper-316L stainless steel layered composite material for high temperature, comprising the following steps:

[0044] Step 1: Clean and degrease the surface of the oxygen-free copper strip with a thickness of 4.5mm and the pure nickel strip with a thickness of 0.09mm. The purity of pure nickel is not lower than the N6 standard. Cleaning with organic solvents, pickling and grinding is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com