Wide-speed-range multi-working-medium efficacy matching combined power system

A technology of combined power and multiple working fluids, which can be applied to combined engines, charging systems, turbine/propulsion fuel delivery systems, etc., and can solve problems such as difficulty in implementation, difficulty in achieving work efficiency, lack of deep fusion fuel, and full utilization of working fluids. , to achieve the effect of ensuring pre-cooling effect, simple structure and high processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

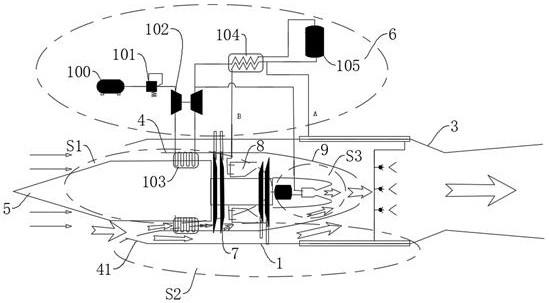

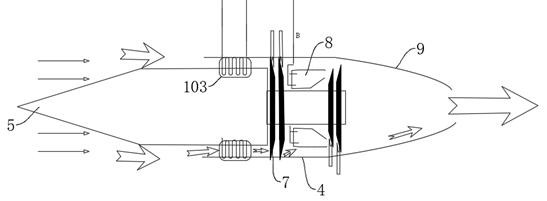

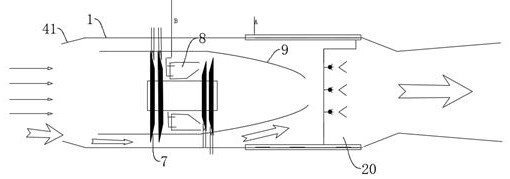

[0024] Such as Figure 1-4 Shown is a wide speed range multi-working medium efficiency matching combined power system, the system is equipped with a circulation system 6, and the system mainly includes a cylinder pipe 1 and a power device, and the power device is built in the cylinder pipe 1 Inside, the front end of the barrel pipe 1 is connected to an air intake pipe 2, and its tail end is connected to a nozzle 3; the power unit includes a turbine power engine S1, a powder rocket engine S3 and a supercharger engine S1 arranged in sequence according to the direction of gas delivery. The role of the combustion ramjet engine S2 is to make full use of the characteristics of each engine, realize the integrated compact design of the engine's full flow channel at the minimum quality cost and space cost, realize the stable and reliable operation of the engine in a wide range, and obtain the highest possible propulsion performance, and the intake pipe 2 is built with a pre-cooling pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com