Method for preparing size-controllable nanoneedle type electrode

A nano-electrode and nano-needle technology, which is applied in the field of electrode preparation and electroanalytical chemistry, can solve the problems of numerous operation steps and uncontrollable nano-electrode size, and achieve the effects of simple operation, low cost and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a size-controllable gold nanometer needle electrode, comprising the steps of:

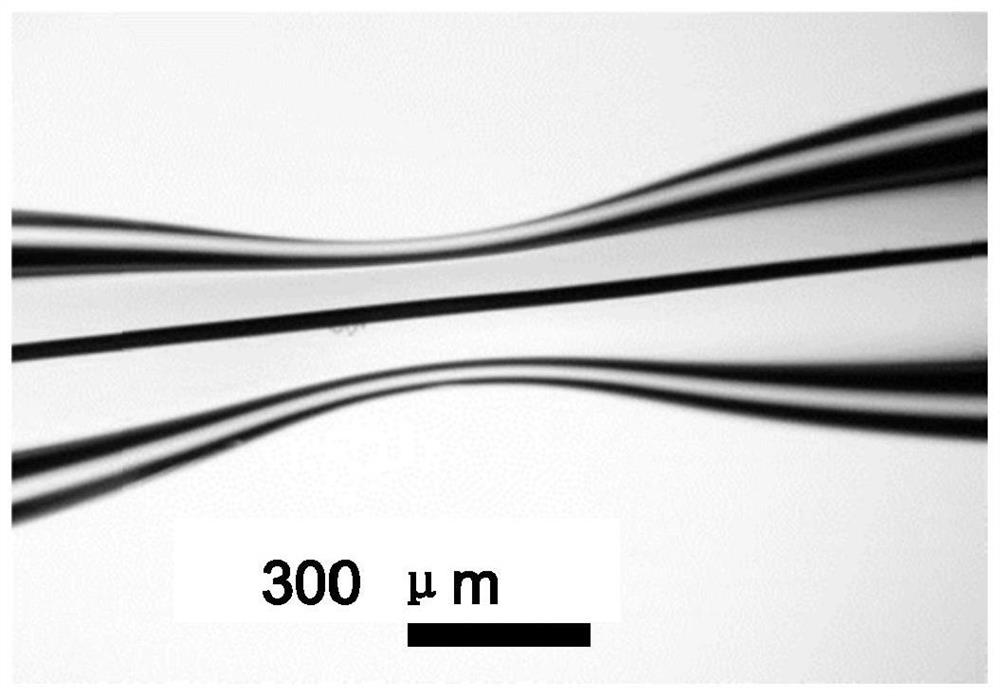

[0032] 1) Place the borosilicate capillary in ethanol solution to remove impurities in the tube by ultrasonic. The inner diameter of the capillary is 0.2mm and the outer diameter is 1.0mm. Use a gold wire with a purity of 99.95%, a diameter of 50 μm, and a length of 2 cm. It penetrates into a borosilicate capillary with a length of 10 cm. The position of the gold wire is in the middle of the capillary. The smaller the size difference between the selected gold wire and the inner diameter of the capillary, the better the gold wire in the drawing process. The better the fit with the capillary.

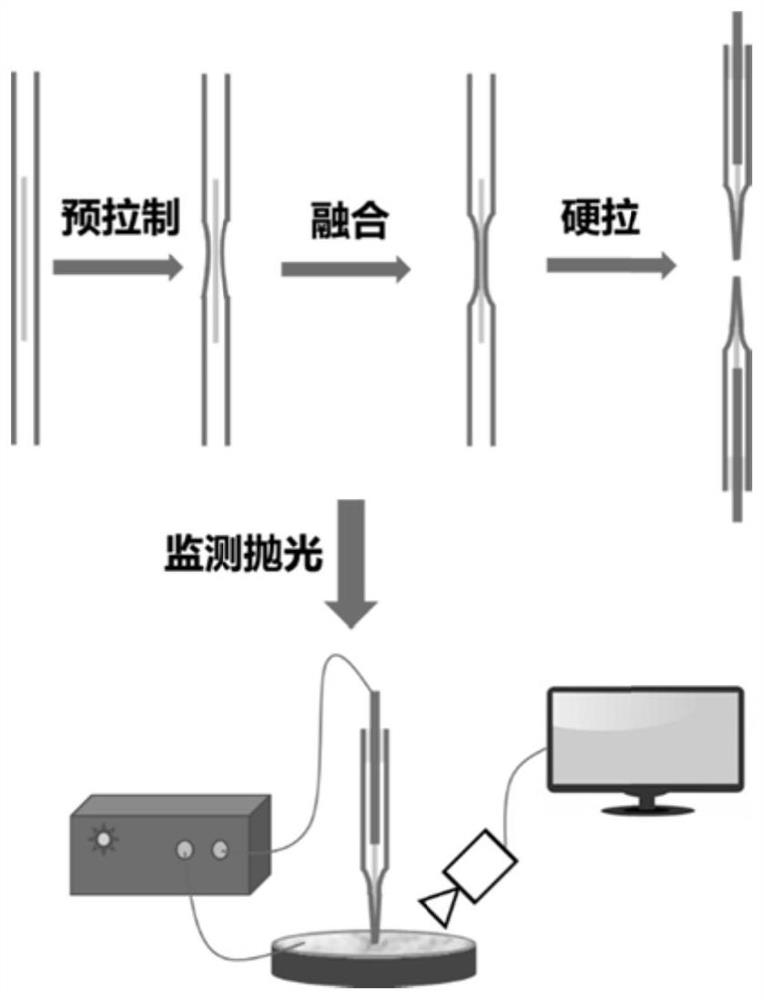

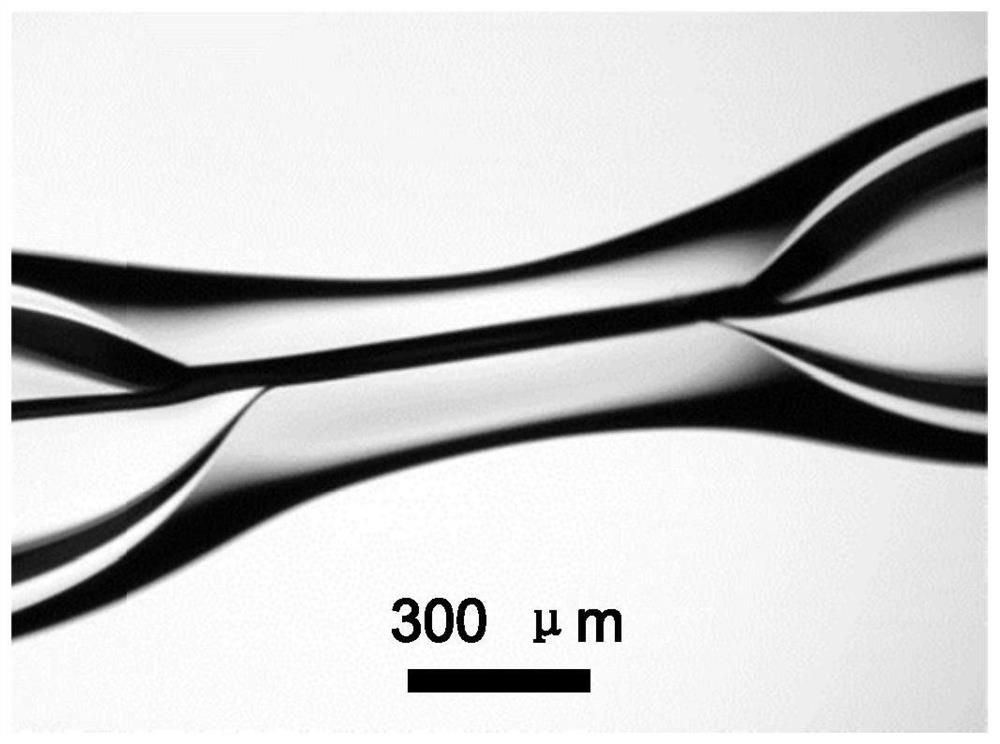

[0033] 2) Install the capillary with gold wire in step 1) in a Sutter-P2000 laser drawing machine for pre-drawing operation, the purpose is to thin the middle part of the capillary so that the gap between it and the internal gold wire becomes smaller. The pre-drawing program is: ...

Embodiment 2

[0043] A method for preparing size-controllable platinum nano-needle electrodes, comprising the steps of:

[0044] 1) Borosilicate capillary inner diameter = 0.6 mm, outer diameter = 1.0 mm. A platinum wire with a purity of 99.95%, a diameter of 50 μm, and a length of 2 cm is used to penetrate into a borosilicate capillary with a length of 10 cm, and the platinum wire is located in the middle of the capillary.

[0045] 2) Pre-draw the capillary tube with platinum wire in step 1, the pre-drawing procedure is: HEAT=450W, FIL=4, VEL=15, DEL=120, PULL=0, the laser signal light flashes 3 times and then turns off Program, natural cooling for 60 seconds.

[0046] 3) The fusion program is: HEAT=400, FIL=4, VEL=15, DEL=120, PULL=0. Stop the program after timing 7s after starting, and cool down naturally for 60 seconds.

[0047] 4) Perform hard pulling operation on the capillary in step 3), hard pulling procedure: HEAT=400, FIL=4, VEL=33, DEL=120, PULL=90.

[0048] 5) Perform precis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com