Intelligent manufacturing production line control system based on Internet of Things

A technology of intelligent manufacturing and control systems, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as easy error in sensor data, unsuitable production equipment, inaccurate automated testing, etc., to improve production accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

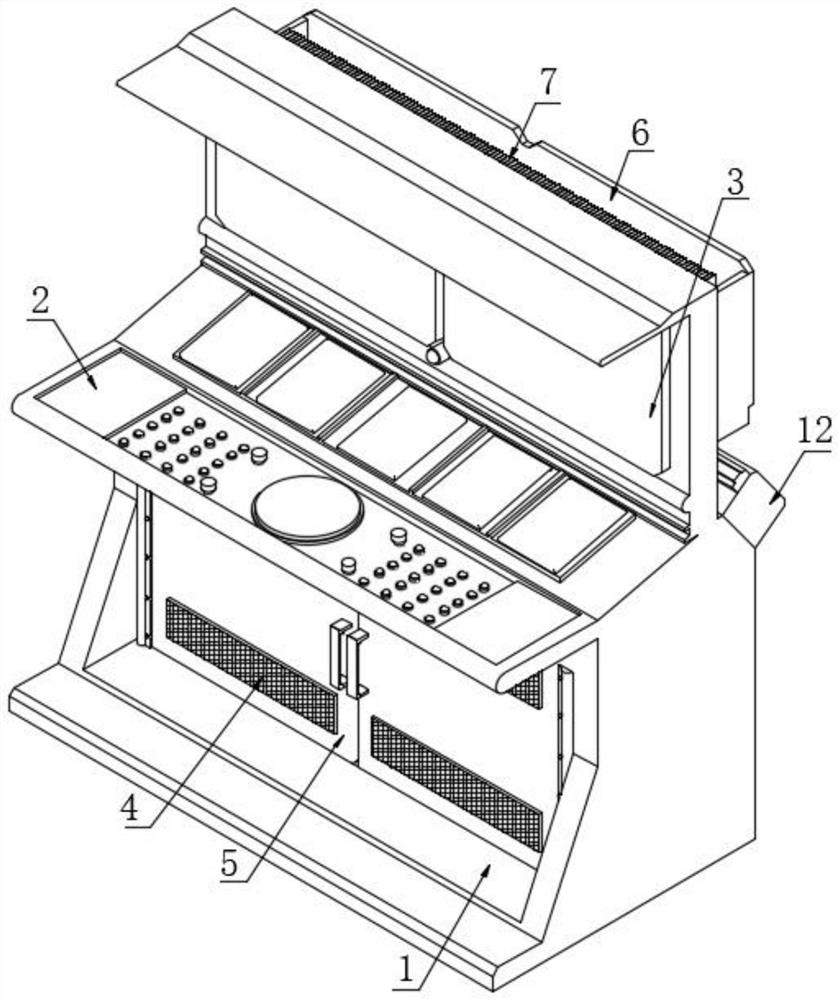

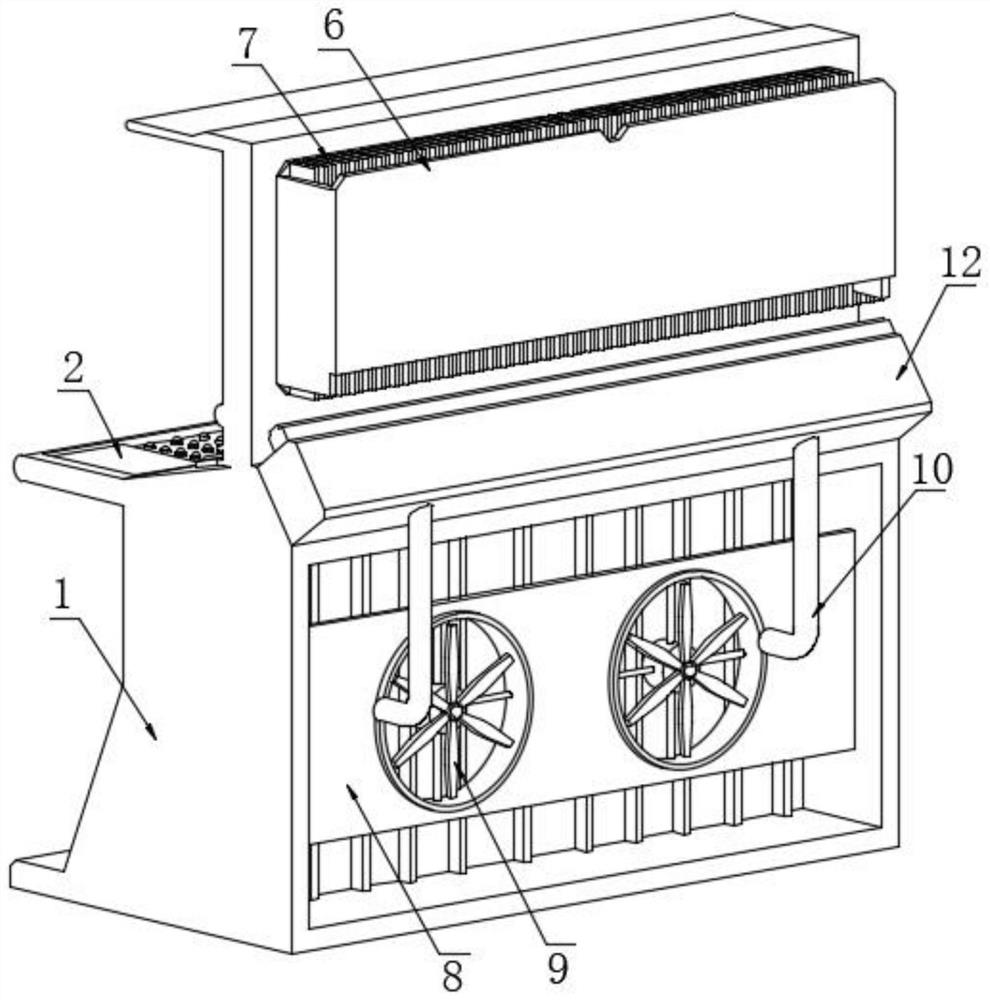

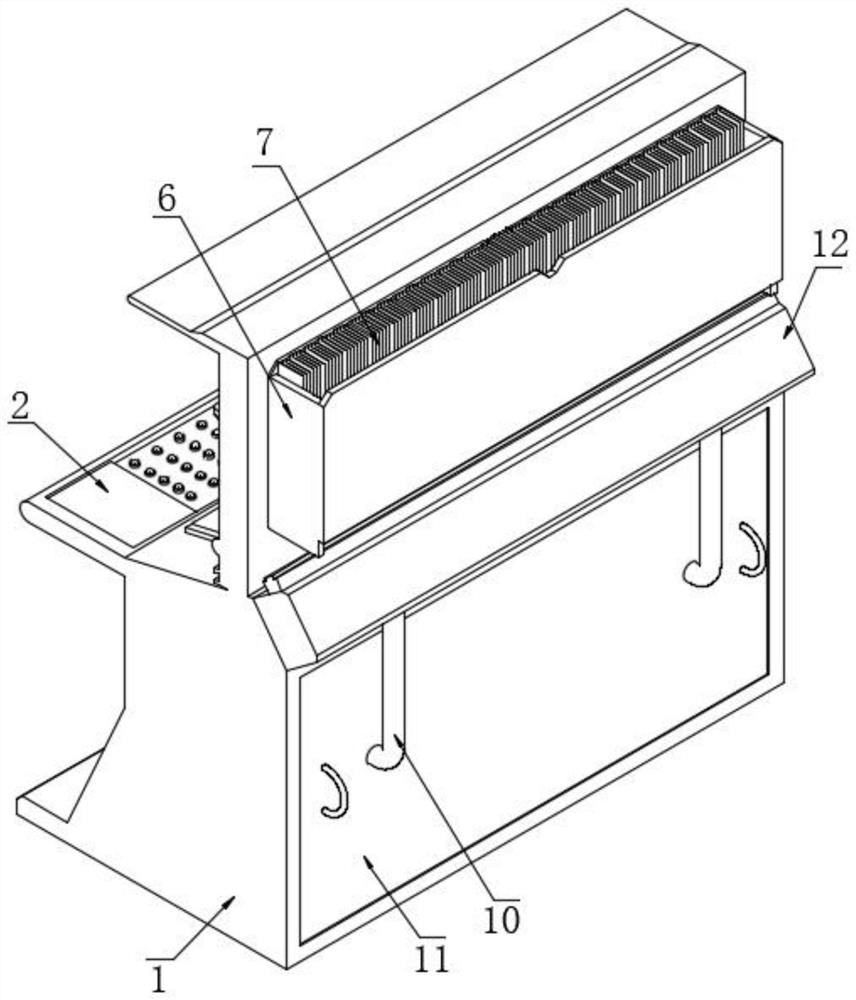

[0054] like Figure 1-10 As shown, the present invention provides a technical solution: an intelligent manufacturing production line control system based on the Internet of Things, including a control cabinet 1, a production line control terminal 2 is provided in the middle of the control cabinet 1, and a display control component is provided on the front of the control cabinet 1 3. There are two opening and closing plates 5 hinged on the lower side of the front of the control cabinet 1. The upper and lower sides of the front of the opening and closing plates 5 are clamped with dust-proof nets 4. The back of the control cabinet 1 is provided with several heat dissipation panels corresponding to the positions of the display and control components 3. 7, several cooling fins 7 are located in the bracket 6, the front of the bracket 6 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com