Nanowire-plasmon coupled single photon emitter and preparation method thereof

A technology of plasmons and nanowires, which is applied in the field of quantum communication, can solve the problems of excessive minimum radius of nanowires, large system structure size, and difficulty in integration, etc., so as to improve single-photon emission rate, increase spontaneous emission rate, and stabilize Emission rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

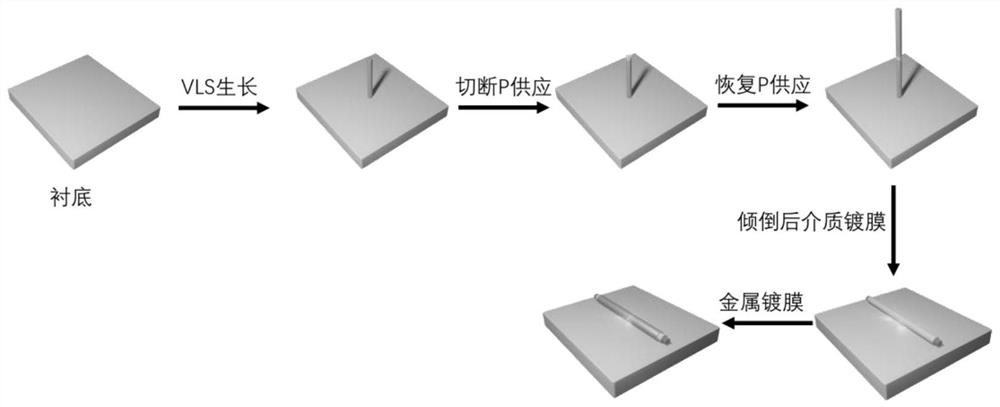

[0036] The present invention also provides a method for preparing the above nanowire-plasmon coupled single photon emitter, comprising the following steps:

[0037] S1 provides a substrate;

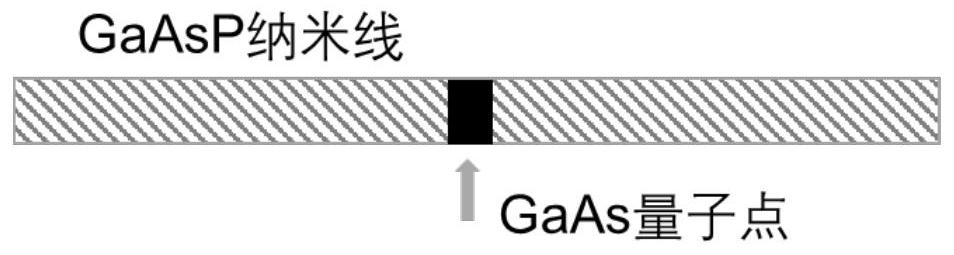

[0038] S2 grow the nanowire body on the substrate; when growing to the height of the quantum dot, replace it with the component growth of the quantum dot, continue to grow the nanowire body until the growth of the nanowire body is completed after the growth of the quantum dot is completed;

[0039] S3 uses an ultrasonic sounder to pour the nanowire body into a horizontal direction;

[0040] S4 uses electron beam evaporation to perform dielectric coating on the nanowire body;

[0041] S5 uses electron beam evaporation to coat the nanowire body with a metal film.

[0042] Preferably, the VLS process is used to grow the nanowire body in the S2 step. VLS is the vapor-liquid-solid process. The impurities in the system can form eutectic catalyst droplets with other components, and the gas raw...

Embodiment 1

[0051] A kind of high-efficiency single-photon emitter described in the present embodiment, its preparation method is as follows:

[0052] (1) provide a substrate, the material of the substrate is silicon dioxide;

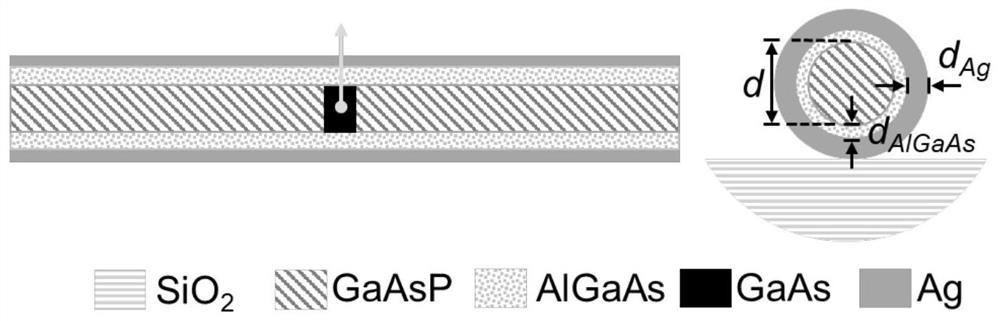

[0053](2) The GaAsP nanowire body is grown on the silicon wafer of the substrate by a Ga-assisted VLS process, the growth temperature is 630° C., and the growth time is 60 minutes. GaAs quantum dot regions are formed in the middle of GaAsP by cutting off the P supply during growth. And increase the beam pressure to compensate for the decrease of phosphorus supply during QD growth. The growth time of QD is 30s. After QD growth, the equivalent beam pressure of As and P molecules returns to the initial state, and the preparation of the nanowire body and quantum dots is completed.

[0054] (3) using an ultrasonic sounder to pour the prepared sample;

[0055] (4) Electron beam evaporation is used to carry out dielectric coating on the sample, the thickness is 10nm, ...

Embodiment 2

[0059] A kind of high-efficiency single-photon emitter described in the present embodiment, its preparation method is as follows:

[0060] (1) provide a substrate, the material of the substrate is silicon dioxide;

[0061] (2) The GaAsP nanowire body is grown on the silicon wafer of the substrate by a Ga-assisted VLS process, the growth temperature is 630° C., and the growth time is 60 minutes. GaAs quantum dot regions are formed in the middle of GaAsP by cutting off the P supply during growth. And increase the beam pressure to compensate for the decrease of phosphorus supply during QD growth. The growth time of QD is 30s. After QD growth, the equivalent beam pressure of As and P molecules returns to the initial state, and the preparation of the nanowire body and quantum dots is completed.

[0062] (3) using an ultrasonic sounder to pour the prepared sample;

[0063] (4) Electron beam evaporation is used to carry out dielectric coating on the sample, the thickness is 10nm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com