Energy-absorbing super-hydrophobic super-oleophobic anti-icing coating for power transmission line and preparation method thereof

A super-hydrophobic, super-oleophobic, transmission line technology, applied in the field of energy-absorbing, super-hydrophobic, super-oleophobic, anti-icing coatings for transmission lines, can solve the problem of the loss of super-hydrophobic performance, the impossibility of large-scale application, and the inability of large-scale application of super-hydrophobic coatings. Long-term use and other problems, to achieve excellent anti-icing performance, good adhesion, and reduce electrical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

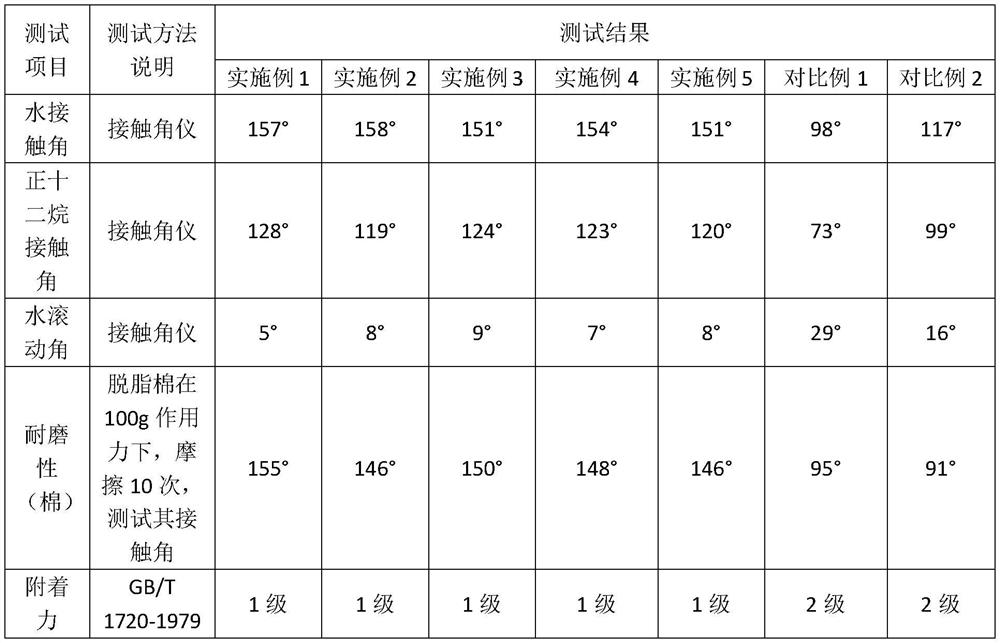

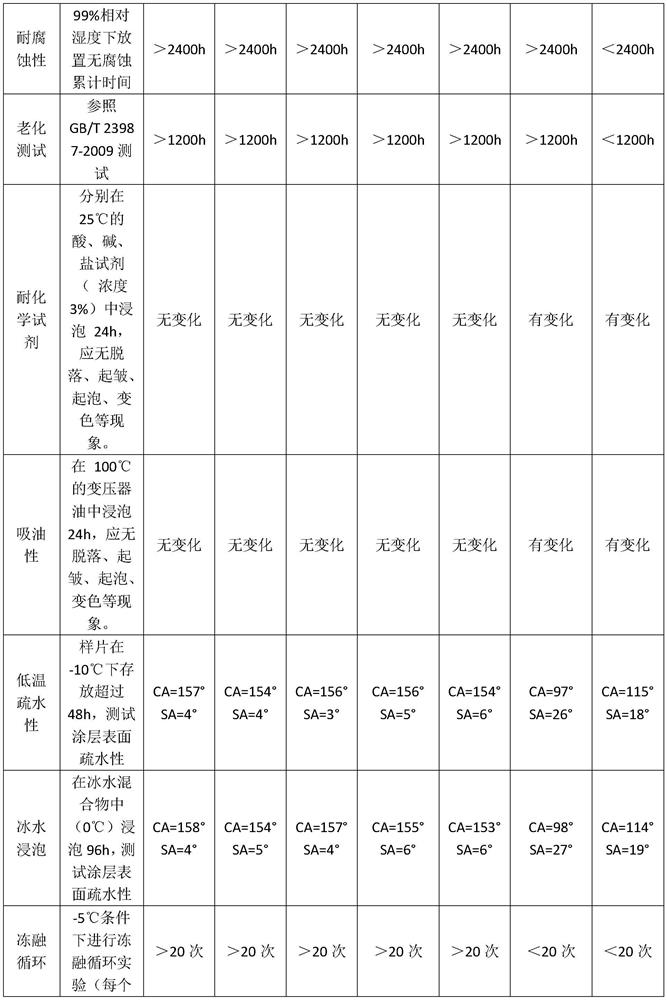

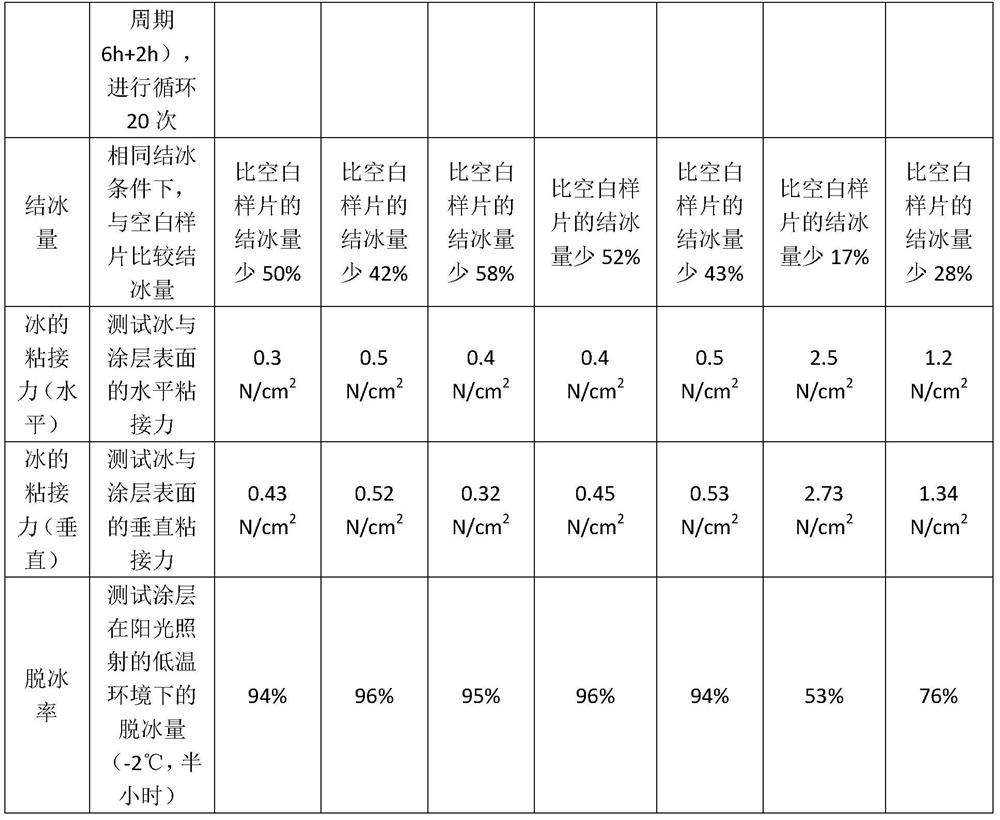

Examples

Embodiment 1

[0028] A preparation method of an energy-absorbing superhydrophobic superoleophobic anti-icing coating for transmission lines is as follows:

[0029] Step 1. Add 5 parts of nano-titanium dioxide, 5 parts of carbon nanotubes, and 10 parts of modified iron oxide black to 22 parts of polytetrafluoroethylene dispersions, stir at a speed of 1500 r / min, and stir at a high speed for 30 minutes to prepare a mixed solution;

[0030] Step 2: Add 57 parts of fluorine-modified silicone resin, 2 parts of 3-aminopropyltrimethoxysilane, 1 part of dispersant 5040, 1 part of leveling agent BYK-300, and 1.5 parts of defoamer to the mixed solution YS-202 antifoaming agent, 0.5 part of perfluorosilicone oil, stirring speed 800r / min, stirring at medium speed for 30 minutes, the preparation can be completed, and the anti-icing coating can be obtained.

[0031] Wherein, the preparation method of polytetrafluoroethylene dispersion comprises:

[0032] S1. Weigh 60 parts of polytetrafluoroethylene pow...

Embodiment 2

[0039] A preparation method of an energy-absorbing superhydrophobic superoleophobic anti-icing coating for transmission lines is as follows:

[0040] Step 1. Add 3 parts of nano-titanium dioxide, 8 parts of carbon nanotubes, and 20 parts of modified iron oxide black to 30 parts of polytetrafluoroethylene dispersion, stir at a speed of 1600 r / min, and stir at a high speed for 30 minutes to prepare a mixed solution;

[0041] Step 2: Add 35 parts of fluorine-modified silicone resin, 1 part of γ-(methoxyacryloyloxy)propyltrimethoxysilane, 0.5 parts of dispersant 5040, 0.5 parts of leveling agent BYK-300, 1.7 parts of antifoaming agent YS-202 defoaming agent, 0.3 parts of perfluorosilicone oil, the stirring speed is 850r / min, and the preparation can be completed after stirring at a medium speed for 30 minutes, and the anti-icing coating is obtained.

[0042] Wherein, the preparation method of polytetrafluoroethylene dispersion comprises:

[0043] S1. Weigh 60 parts of polytetraflu...

Embodiment 3

[0050]A preparation method of an energy-absorbing superhydrophobic superoleophobic anti-icing coating for transmission lines is as follows:

[0051] Step 1. Add 5 parts of nano-titanium dioxide, 3 parts of carbon nanotubes, and 12 parts of modified iron oxide black to 26 parts of polytetrafluoroethylene dispersion liquid, stir at a speed of 1700 r / min, and stir at a high speed for 30 min to prepare a mixed liquid;

[0052] Step 2: Add 50 parts of fluorine-modified silicone resin, 1 part of 3-aminopropyltrimethoxysilane, 0.5 parts of dispersant 5040, 0.5 parts of leveling agent BYK-300, and 1.5 parts of defoamer to the mixed solution YS-202 antifoaming agent, 0.5 part of perfluorosilicone oil, stirring speed 900r / min, stirring at medium speed for 30 minutes, the preparation can be completed, and the anti-icing coating can be obtained.

[0053] Wherein, the preparation method of polytetrafluoroethylene dispersion is:

[0054] S1. Weigh 70 parts of polytetrafluoroethylene powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com