Biodegradable lubricating oil composition, lubricating oil and preparation method and application thereof

A lubricating oil composition and biodegradation technology, applied in the field of lubricating oil, can solve the problems of affecting ecological balance, polluting water and soil, running, running, dripping, leaking, etc., to maintain ecological balance, broad application prospects, and protect the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] In one embodiment, the viscosity grade of the lubricating oil is one of ISO VG150, ISO VG220, and ISO VG320. In this embodiment, different viscosity grades can be used with wind power equipment in a variety of different environments and conditions.

[0035] The use of the lubricating oil obtained by adopting the first aspect of the present disclosure and the second aspect of the present disclosure in the transmission system of wind power generation equipment.

[0036] The present disclosure is further illustrated below by way of examples, but the present disclosure is not thereby subject to any limitation.

[0037] The materials, reagents, instruments and equipment used in the examples of the present disclosure can be obtained from commercial sources unless otherwise specified.

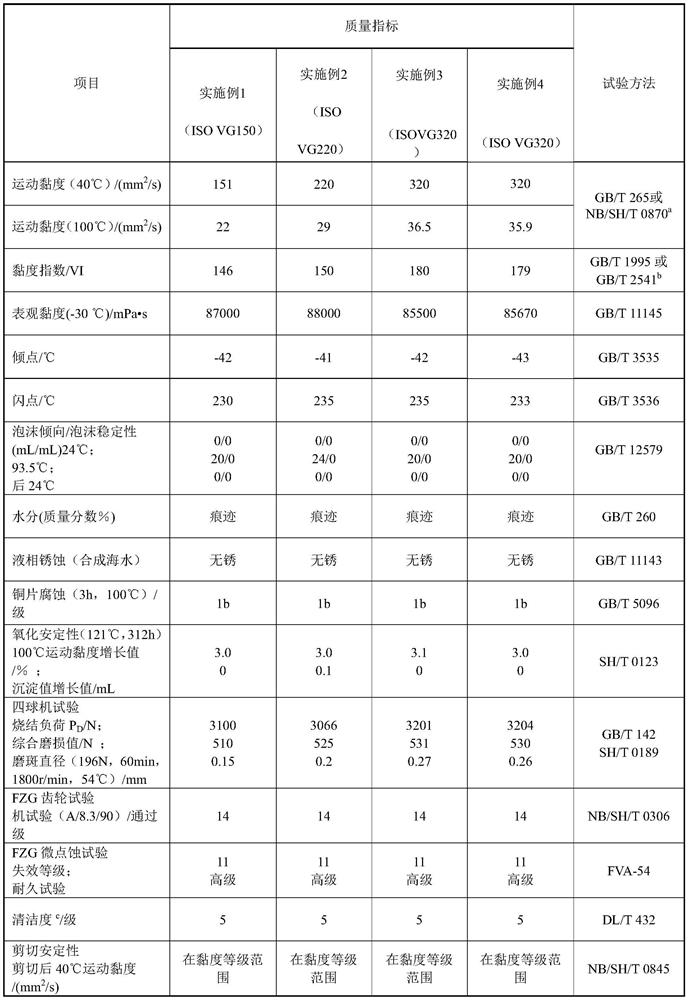

Embodiment 1

[0039] 1 part by weight of sulfurized fatty acid ester, 2.5 parts by weight of calcium sulfonate, 2.5 parts by weight of alkyl diphenylamine, 0.005 part by weight of disodium edetate, 1 part by weight of polymethacrylate, and 0.4 parts by weight of tributyl phosphate parts, 0.003 parts by weight of silicone-polyacrylate, 75 parts by weight of azelaic acid ester, 350 parts by weight of trimethylolpropane ester and 68 parts by weight of polyester 300. At 65°C, stir for 4 hours to prepare ISO VG150 Viscosity grade biodegradable wind power gear oil, the product performance is shown in Table 1.

Embodiment 2

[0041] The preparation method of the biodegradable wind power gear oil is the same as in Example 1, the difference is that each substance is prepared according to 1 part by weight of sulfurized fatty acid ester, 2.25 parts by weight of dodecenyl succinic acid half ester, 2,6-di-tert-butyl p- 3.5 parts by weight of cresol, 0.004 parts by weight of disodium ethylenediaminetetraacetate, 1 part by weight of polymethacrylate, 0.4 parts by weight of phosphorus nitriding modified methyl oleate, 0.00075 parts by weight of silicone-polyacrylate, three 350 parts by weight of methylol propane ester and 142 parts by weight of polyester 300 are blended into ISO VG220 viscosity grade biodegradable wind power gear oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com