Heat treatment method of steel bearing ring

A heat treatment method and technology of bearing rings, which are applied in the field of bearing manufacturing, can solve problems such as low impact toughness and poor dimensional stability, and achieve the effects of improving wear resistance, reducing hardness deviation, and efficient heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

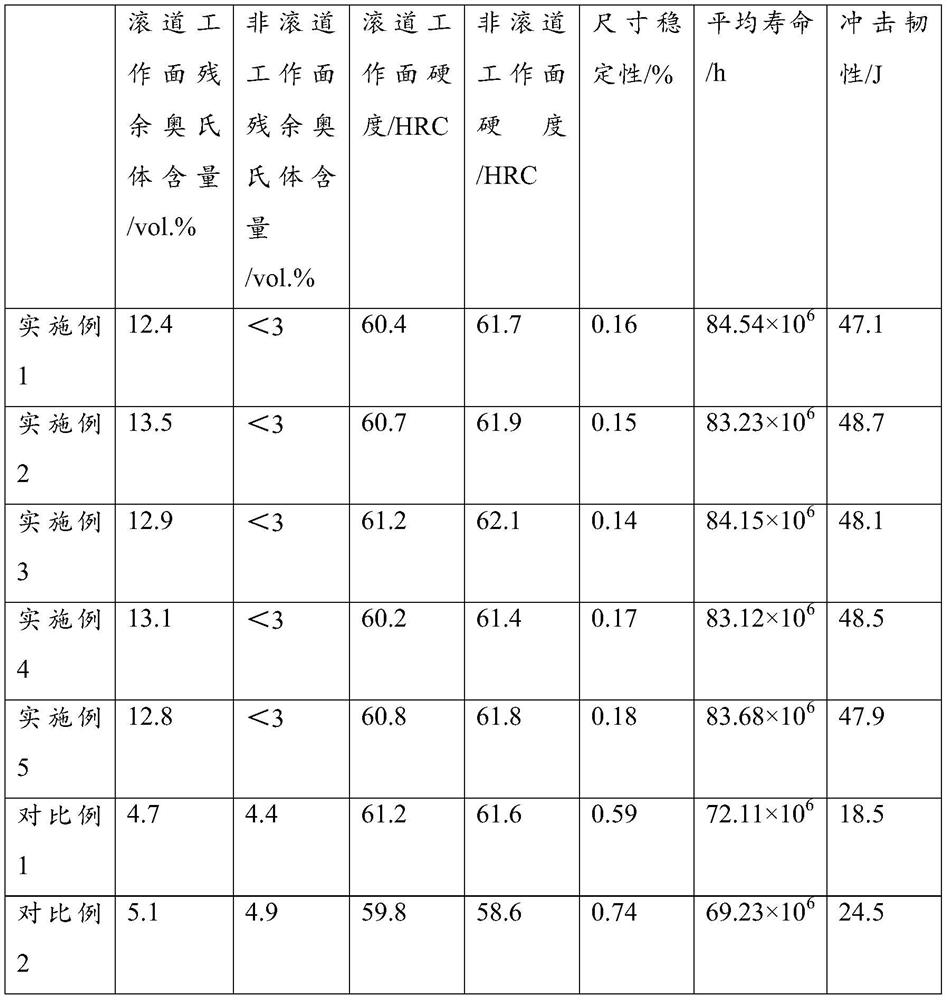

Examples

Embodiment 1

[0026] This embodiment proposes a heat treatment method for a steel bearing ring, comprising the following steps:

[0027] S1. The steel bearing ring is quenched in an atmosphere furnace, the heating rate is 10°C / min, the thickness of the steel bearing ring is 9.2mm, the austenitizing temperature is 890°C, and the holding time is 27min. Immediately cool to room temperature with oil at 70°C; the overall retained austenite content of the steel bearing ring after quenching is 18vol.%;

[0028] S2. Perform gradient tempering heat treatment on the steel bearing rings treated in step S1, control the average heating rate of the gradient tempering temperature field on the raceway working surface to 80°C / s, raise the temperature to 373.4°C, The average heating rate is 58°C / s, the temperature is raised to 313.1°C, and air-cooled after heating; the heating method of the gradient tempering heat treatment is induction heating, and the heating time is 4.5s. Further, a pure copper round imit...

Embodiment 2

[0031] This embodiment proposes a heat treatment method for a steel bearing ring, comprising the following steps:

[0032] S1. The steel bearing ring is quenched in an atmosphere furnace, the heating rate is 20°C / min, the thickness of the steel bearing ring is 9.2mm, the austenitizing temperature is 870°C, and the holding time is 35min. Immediately cool to room temperature with oil at 65°C; the overall retained austenite content of the steel bearing ring after quenching is 19.1vol.%;

[0033] S2. Perform gradient tempering heat treatment on the steel bearing rings treated in step S1, control the average heating rate of the gradient tempering temperature field on the working surface of the raceway to 90°C / s, and raise the temperature to 375.7°C. The average heating rate is 60°C / s, the temperature is raised to 250.7°C, and air-cooled after heating; the heating method of the gradient tempering heat treatment is induction heating, and the heating time is 4s. ; In the induction he...

Embodiment 3

[0036]This embodiment proposes a heat treatment method for a steel bearing ring, comprising the following steps:

[0037] S1. The steel bearing ring is quenched in an atmosphere furnace, the heating rate is 30°C / min, the thickness of the steel bearing ring is 9.2mm, the austenitizing holding temperature is 910°C, and the holding time is 10min. Immediately cool to room temperature with oil at 60°C; the overall retained austenite content of the steel bearing ring after quenching is 17.8vol.%;

[0038] S2. Perform gradient tempering heat treatment on the steel bearing rings treated in step S1, control the average heating rate of the gradient tempering temperature field on the raceway working surface to 50°C / s, raise the temperature to 360.4°C, The average heating rate is 49°C / s, the temperature is raised to 298.2°C, and air-cooled after heating; the heating method of the gradient tempering heat treatment is induction heating, and the heating time is 7s. ; In the induction heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com