Metal packaging ceramic ball composite armor, preparation method and multi-projectile-resistant light target plate

A technology of metal packaging and ceramic balls, which is applied to the structure of armor plates, armor, protective equipment, etc., can solve the problems of flexible steel mesh, poor confinement effect of ceramic balls, and difficult fixing of ceramic balls, so as to change the layout mode and Size matching, excellent anti-multiple-shot performance, and the effect of improving the anti-multiple-shot performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

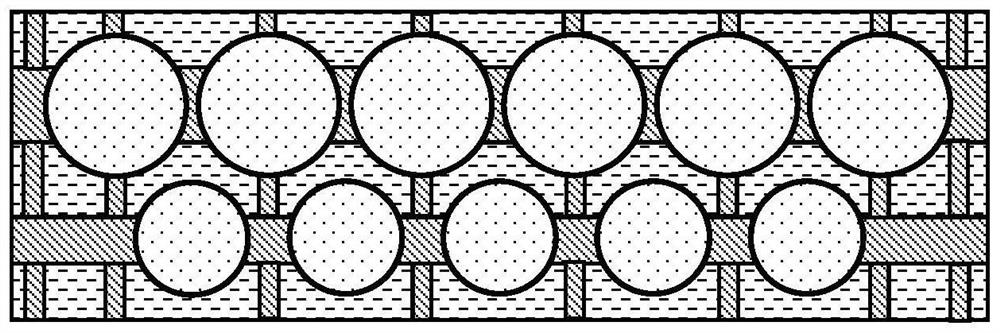

[0051] A TC4 titanium alloy / 6063 aluminum alloy packaged ceramic ball composite armor and its preparation method, the cross-sectional view of the ceramic ball arrangement is as follows figure 1 As shown, the top view is as Figure 5 As shown in (a), the composite armor includes three TC4 titanium alloy layers, ceramic balls fixed in the circular holes between each two layers of titanium alloy layers, and filling the through holes of the titanium alloy layer and the pores between the titanium alloy layer and the ceramic balls aluminum alloy layer. The thickness of the middle layer of the titanium alloy layer is 8mm, the top layer and the bottom layer are both 6mm, the depth of the first round hole on one surface of the top layer and the middle layer is 4mm, and the hole diameter is 15.9mm, and the hole depth of the second round hole on the other surface of the middle layer and the bottom layer is 4mm. The diameter of the hole is 12.5mm, the diameter of the first size ceramic ...

Embodiment 2

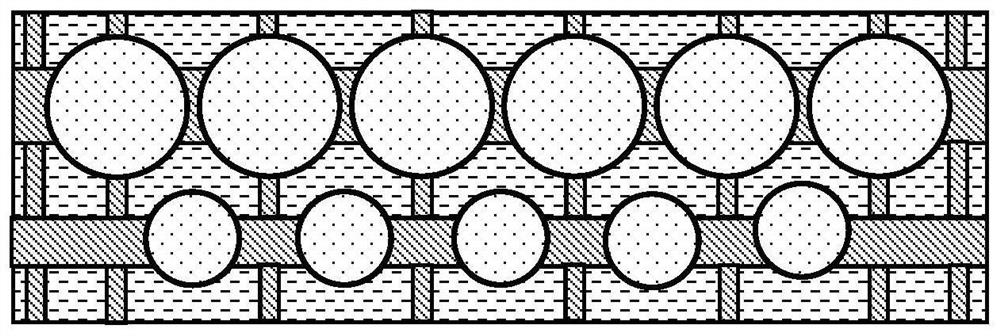

[0061] A TC4 titanium alloy / 6063 aluminum alloy packaged ceramic ball composite armor and its preparation method, the cross-sectional view of the ceramic ball arrangement is as follows figure 2 As shown, the top view is as Figure 5 As shown in (b), the composite armor includes three layers of TC4 titanium alloy layers, ceramic balls fixed in the circular holes between each two layers of titanium alloy layers, and filling the through holes of the titanium alloy layer and the pores between the titanium alloy layer and the ceramic balls aluminum alloy layer. The thickness of the middle layer of the titanium alloy layer is 8mm, the top layer and the bottom layer are both 6mm, the depth of the first round hole on one surface of the top layer and the middle layer is 4mm, and the hole diameter is 15.9mm, and the hole depth of the second round hole on the other surface of the middle layer and the bottom layer is 4mm. The diameter of the hole is 10.5mm, the diameter of the first siz...

Embodiment 3

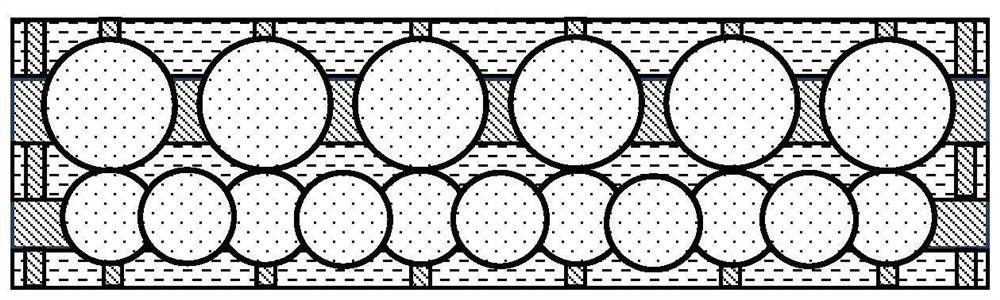

[0071] A TC4 titanium alloy / 6063 aluminum alloy packaged ceramic ball composite armor and its preparation method, the cross-sectional view of the ceramic ball arrangement is as follows image 3 As shown, the top view is as Figure 5 As shown in (c), the target plate includes three layers of TC4 titanium alloy layers, ceramic balls fixed in the circular holes between each two layers of titanium alloy layers, and an aluminum alloy layer filling the pores between the titanium alloy layers and the ceramic balls. The thickness of the middle layer of the titanium alloy layer is 8mm, the top layer and the bottom layer are both 6mm, the depth of the first round hole on one surface of the top layer and the middle layer is 4mm, and the hole diameter is 15.9mm, and the hole depth of the second round hole on the other surface of the middle layer and the bottom layer is 4mm. The diameter of the hole is 10.5mm, the diameter of the first size ceramic ball is 15mm, embedded and fixed in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com