Numerical control end face cylindrical grinding machine for efficiently and ultraprecisely grinding high-speed cutter handle

A cylindrical grinding machine and ultra-precision technology, which is applied to machine tools designed for grinding the rotating surface of workpieces, grinding machine parts, and grinding machines. problems, to achieve the effect of reducing labor dependence, reducing adjustment time, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

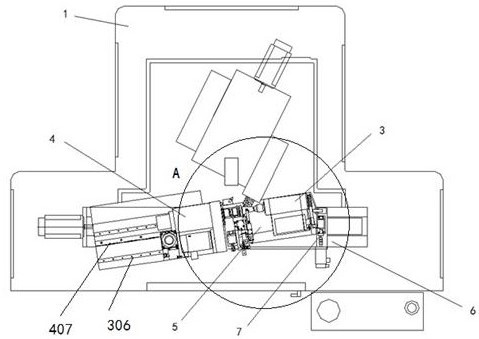

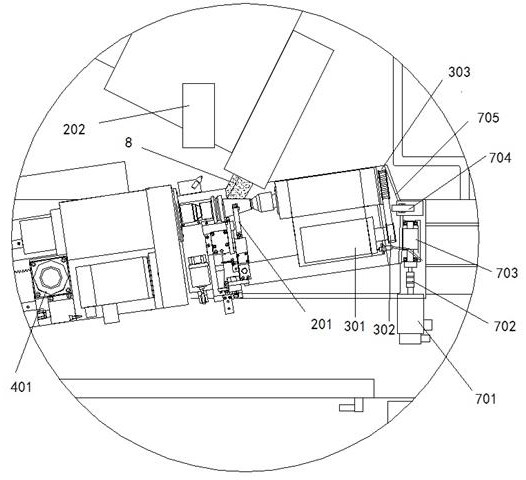

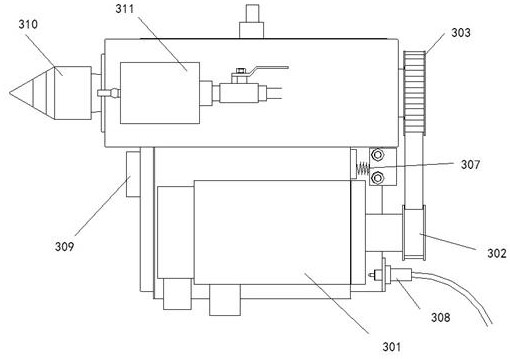

[0037] A CNC end face cylindrical grinder for high-efficiency ultra-precision grinding of high-speed tool handles, including a bed 1, a tool handle outer diameter measuring instrument 201, an end surface measuring instrument 202, a tailstock device 3, a headstock device 4, an upper workbench 5, The lower workbench 6 and the upper workbench angle adjustment device 7 also include a coolant tank on which a constant temperature air conditioner is installed; the inside of the coolant tank is provided with a precision filter bag filter. A V-shaped workpiece bracket 9 is arranged between the tailstock device 3 and the headstock device 4 .

[0038] The coolant tank is equipped with a constant temperature air conditioner, which can adjust the temperature within 0.5 degrees Celsius. The coolant tank is equipped with a precision filter bag filter, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com