Preparation method of flame-retardant environment-friendly high-strength board

A high-strength, environmentally-friendly technology, applied in wood treatment, flat products, impregnated wood, etc., to achieve the effects of protecting the ecological environment, increasing the economic benefits of enterprises, and meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

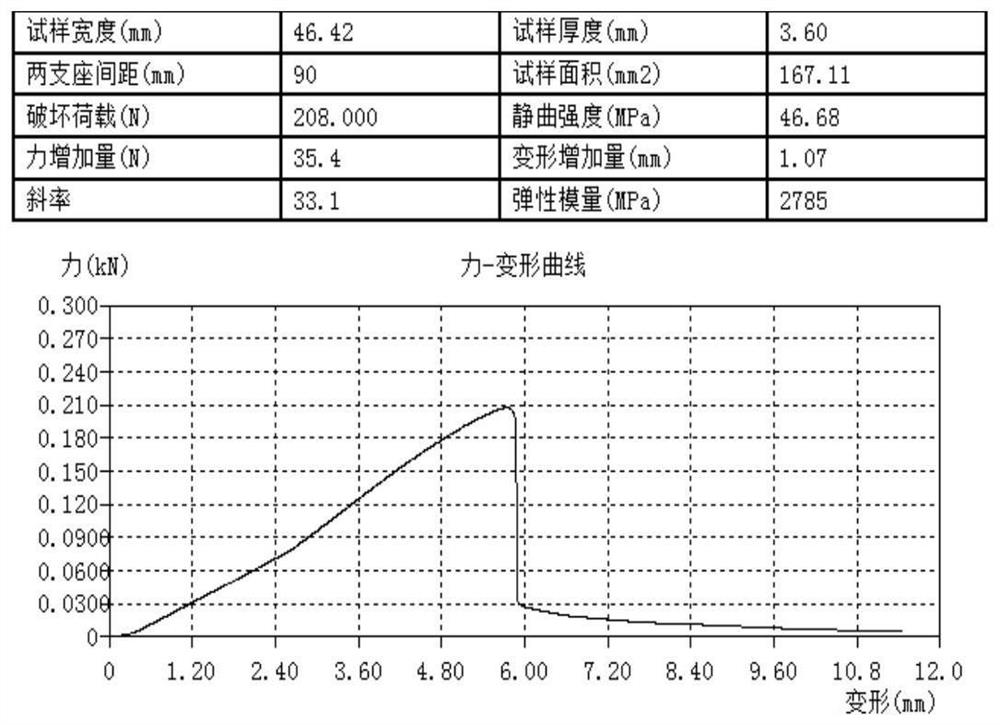

Image

Examples

Embodiment 1

[0020] The present invention will be described in further detail below in conjunction with examples: the waste rubber wood left over from rubber wood processing enterprises and has no additional value is mechanically crushed and screened, and the particles with a particle size of 1-3 cm are chemically pretreated, and hydrogen with a pH value of 13 The sodium oxide aqueous solution was soaked for 3 hours at a ratio of 1:10 (w / w), so that the fibers were fully softened and swollen and part of the lignin was separated. The chemically pretreated raw material is mixed with 3wt% aluminum hydroxide and then ground at a speed of 300rpm for 6h, and the fiber length in the swollen raw material after grinding is 0.5-30mm. Evenly pave the ground and swollen raw materials in the mold, and pre-press for 2-5 minutes under a pressure of 4MPa. Then, under the conditions of pressure of 3 MPa, hot pressing temperature of 130° C., and hot pressing time of 3 hours, the milled raw materials were pu...

Embodiment 2

[0022] The present invention will be described in further detail below in conjunction with examples: the waste rubber wood left over from rubber wood processing enterprises and has no additional value is mechanically crushed and screened, and the particles with a particle size of 1-3 cm are chemically pretreated, and hydrogen with a pH value of 14 The sodium oxide aqueous solution was soaked at a ratio of 1:4 (w / w) for 6 hours, so that the fibers were fully softened and swollen and part of the lignin was separated. The chemically pretreated raw material is mixed with 5wt% magnesia and ground at a speed of 300rpm for 4h, and the fiber length in the swollen raw material after grinding is 0.5-30mm. Evenly pave the ground and swollen raw materials in the mold, and pre-press for 2-5 minutes under a pressure of 4 MPa. Then, under the working conditions of a pressure of 6 MPa, a hot pressing temperature of 120° C., and a hot pressing time of 2 h, the milled raw materials were put int...

Embodiment 3

[0024] The present invention will be described in further detail below in conjunction with examples: the waste rubber wood left over from rubber wood processing enterprises and has no additional value is mechanically crushed and screened, and the particles with a particle size of 1-3 cm are chemically pretreated, and the oxidized rubber wood with a pH value of 10 Magnesium aqueous solution was soaked for 3 hours at a ratio of 1:5 (w / w), so that the fibers were fully softened and swollen and part of the lignin was separated. The raw material after chemical pretreatment is mixed with 15wt% aluminum diethylphosphinate and ground at 500rpm for 2 hours, and the fiber length in the swollen raw material after grinding is 0.5-30mm. Evenly pave the ground and swollen raw materials in the mold, and pre-press for 2-5 minutes under a pressure of 4 MPa. Then, under the conditions of pressure of 6 MPa, hot pressing temperature of 90° C., and hot pressing time of 3 h, the pulverized raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com