Clutch-based planetary gear shifting electric drive axle

A clutch and electric drive technology, which is applied to electric power units, power units, axles, etc., can solve the problems of large space occupied by the powertrain, low reliability of shift actuators, and high difficulty of shift control logic, and saves energy. The effect of chassis space, weight reduction, and compact powertrain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

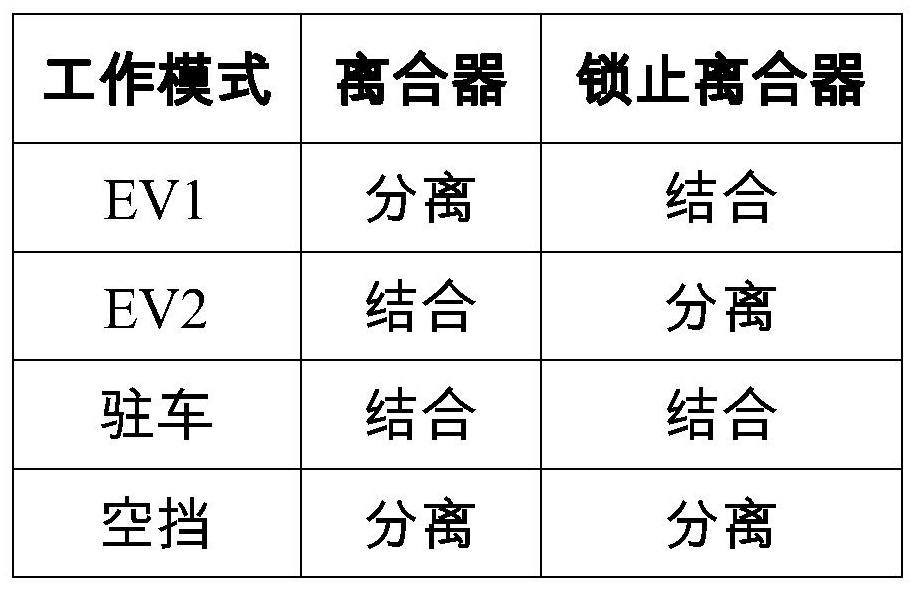

[0032] In order to make the objects, characteristics, advantages of the present invention, the technical solutions in the present invention will be described in conjunction with the drawings in the present embodiment, and will be described below, and the embodiments described below will be described below. Example is only a part of the embodiments of the invention, not all of the embodiments. Based on the embodiments of this patent, there are all other embodiments obtained without making creative labor without making creative labor premises.

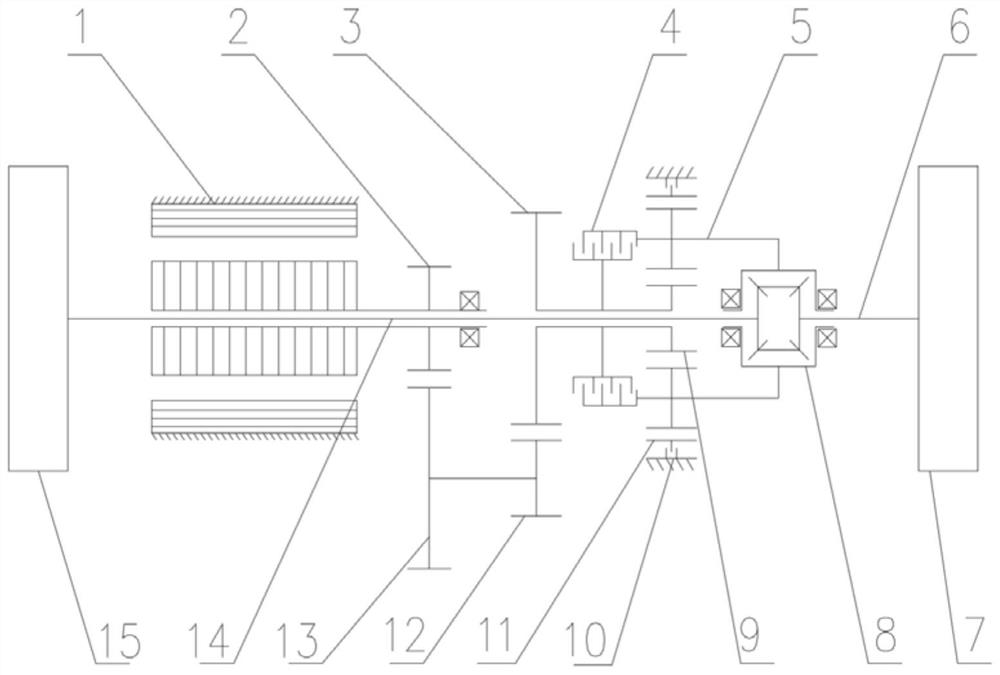

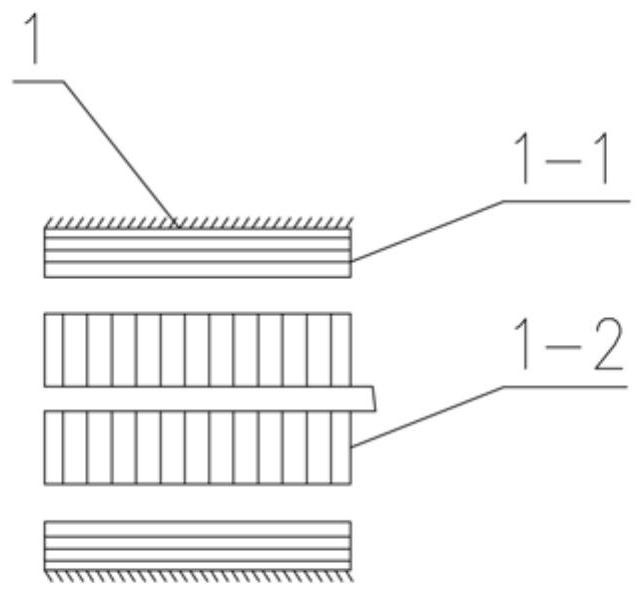

[0033] like figure 1 As shown, the present invention discloses a clutch planetary electric drive bridge including a left half shaft 14, a right half shaft 6, and a drive motor 1 integrated within the vehicle body bridge shell, the first transmission gear 2, the second transmission. Gear 13, the third drive gear 12, the fourth drive gear 3, the planetary transmission mechanism, the lock clutch 10, clutch 4, and differential 8;

[0034] The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com