Intelligent tower crane material transportation control method and system based on stacking model simulation

A model simulation and intelligent tower technology, applied in the field of tower cranes, can solve problems such as danger, operational errors, and unclear command signals, so as to avoid affecting normal construction operations and optimize space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

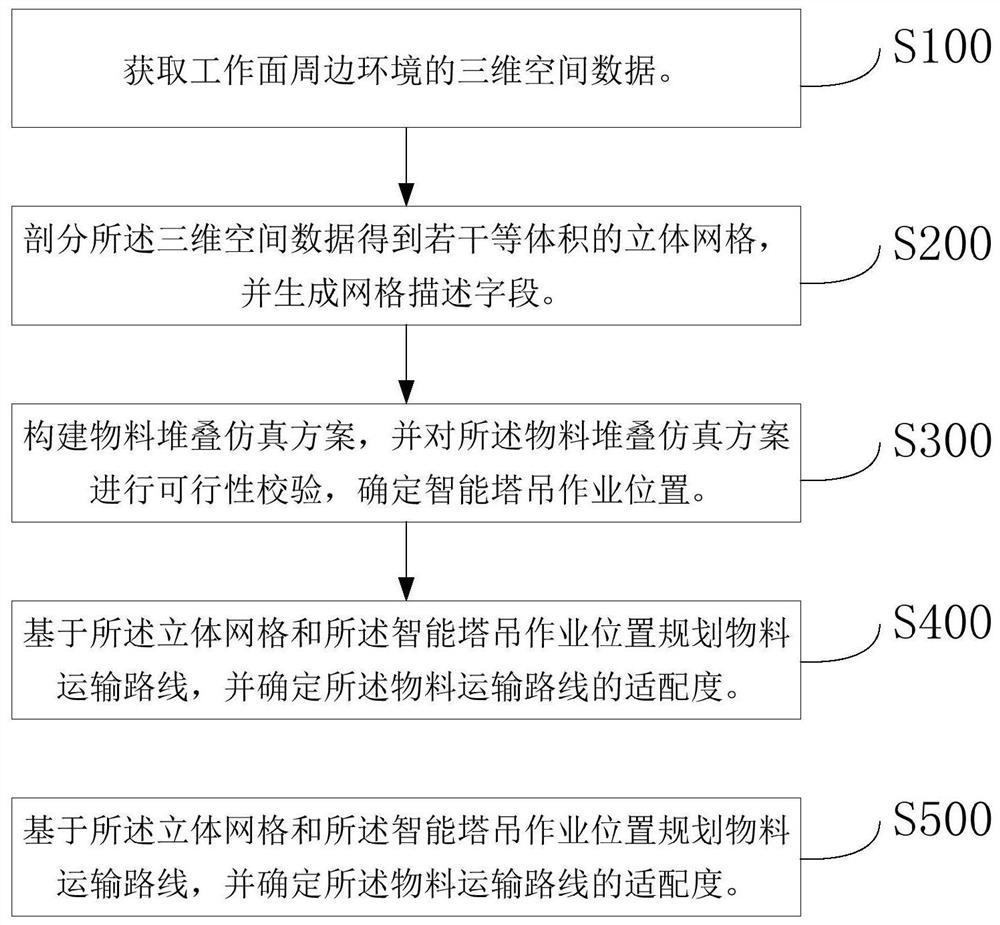

[0059] Refer below figure 1 An embodiment of a method for controlling material transportation of a tower crane based on stacking model simulation disclosed in this application is described in detail. Such as figure 1 As shown, the method disclosed in this embodiment mainly includes the following steps 100 to 500 .

[0060] Step 100, acquiring three-dimensional spatial data of the surrounding environment of the working face.

[0061]Specifically, the working surface refers to the construction engineering working surface area where the materials to be transported are placed or to be placed, the three-dimensional space data is at least one of image, video, and point cloud data, and several Lidar and / or camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com