A kind of low-temperature frost-resistant concrete and its production process

A concrete and low-temperature technology, applied in the field of low-temperature anti-freezing concrete and its production technology, can solve the problems of low mechanical properties, poor low-temperature anti-freezing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A low-temperature antifreeze concrete, comprising the following raw materials by weight: 300 parts of cement, 10 parts of superplasticizer, 50 parts of strengthening and toughening agent, 10 parts of triethylenetetramine, 120 parts of fly ash, 300 parts of medium sand, 100 parts of water;

[0043] The low-temperature frost-resistant concrete is made by the following steps:

[0044]The above-mentioned raw materials are weighed, and the above-mentioned raw materials are mixed uniformly to obtain low-temperature antifreeze concrete.

[0045] Described potent water reducing agent is made by the following steps:

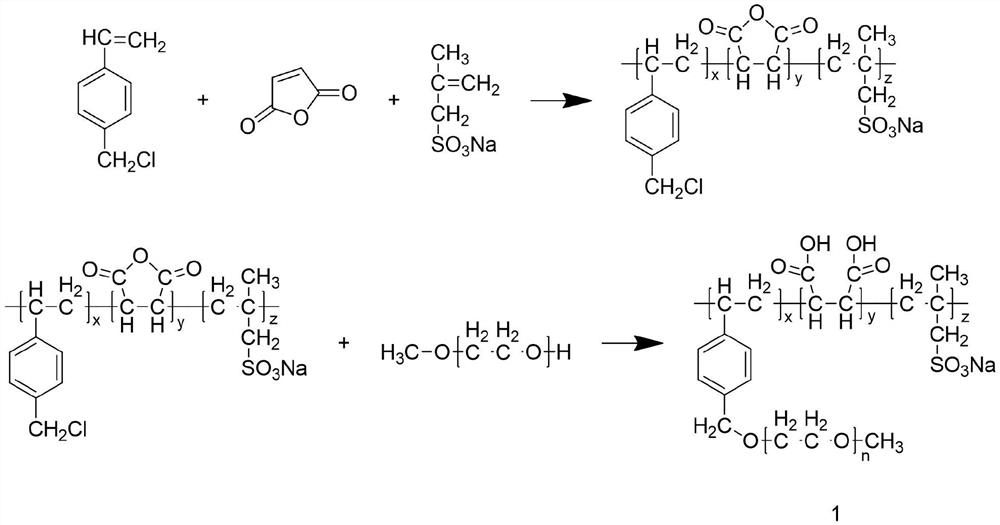

[0046] Step A1: Mix p-chloromethyl styrene, maleic anhydride, sodium methacrylic acid sulfonate, dibenzoyl peroxide, and toluene evenly, and carry out the reaction under the conditions of a rotating speed of 150 r / min and a temperature of 70 °C After 5 hours, polyethylene glycol monomethyl ether and sodium hydroxide solution were added, and the reaction was carri...

Embodiment 2

[0055] A low-temperature antifreeze concrete, comprising the following raw materials by weight: 330 parts of cement, 13 parts of superplasticizer, 55 parts of strengthening and toughening agent, 13 parts of triethylenetetramine, 125 parts of fly ash, 350 parts of medium sand, 125 parts of water;

[0056] The low-temperature frost-resistant concrete is made by the following steps:

[0057] The above-mentioned raw materials are weighed, and the above-mentioned raw materials are mixed uniformly to obtain low-temperature antifreeze concrete.

[0058] Described potent water reducing agent is made by the following steps:

[0059] Step A1: Mix p-chloromethyl styrene, maleic anhydride, sodium methacrylic acid sulfonate, dibenzoyl peroxide, and toluene evenly, and carry out the reaction under the conditions of a rotating speed of 180 r / min and a temperature of 75 °C After 6 hours, polyethylene glycol monomethyl ether and sodium hydroxide solution were added, and the reaction was carr...

Embodiment 3

[0068] A low-temperature antifreeze concrete, comprising the following raw materials by weight: 350 parts of cement, 15 parts of superplasticizer, 60 parts of strengthening and toughening agent, 15 parts of triethylenetetramine, 130 parts of fly ash, 400 parts of medium sand, 150 parts of water;

[0069] The low-temperature frost-resistant concrete is made by the following steps:

[0070] The above-mentioned raw materials are weighed, and the above-mentioned raw materials are mixed uniformly to obtain low-temperature antifreeze concrete.

[0071] Described potent water reducing agent is made by the following steps:

[0072] Step A1: Mix p-chloromethyl styrene, maleic anhydride, sodium methacrylic acid sulfonate, dibenzoyl peroxide, and toluene evenly, and carry out the reaction under the conditions of a rotating speed of 180 r / min and a temperature of 80 °C After 7 hours, polyethylene glycol monomethyl ether and sodium hydroxide solution were added, and the reaction was carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com