Composite anti-counterfeiting film preparation method based on photonic band gap matching

A photonic band gap and thin film preparation technology, which is applied in the field of compound anti-counterfeit structural color thin film preparation, can solve the problems of high cost, complicated verification, cumbersome preparation of anti-counterfeit film, etc., and achieve the effect of low cost, fast response and difficult imitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

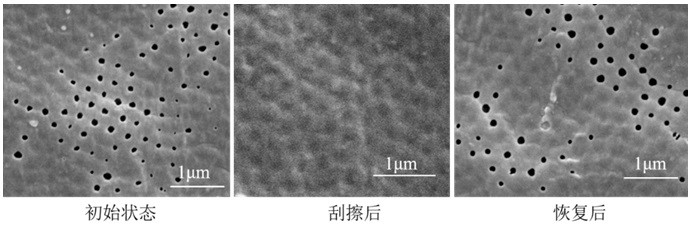

[0032] Such as Figure 1 to Figure 9 Shown, a kind of composite anti-counterfeit film preparation method based on photonic bandgap matching comprises the following steps:

[0033] S1. Soak the substrate in the ethanol dispersion of nano-microspheres of different particle sizes, and pull up at a constant speed to obtain a photonic crystal structure; The fluorescence spectrum peak of the long afterglow anti-counterfeiting pattern at the bottom; the nano-microspheres are SiO 2 , PMMA, polystyrene, a kind of in CdS nano microsphere, the ethanol dispersion liquid concentration that is used for pulling is 2-8wt%, and the upward pulling speed is 2-6 μ m / s;

[0034]S2. Add the ethanol-diluted epoxy resin pregel dropwise on the surface of the photonic crystal, and cure it on a constant temperature heating platform, and then pattern the long afterglow layer. The epoxy resin pregel, black particles Mix evenly with rare earth strontium aluminate powder in a certain proportion, pour it i...

Embodiment 1

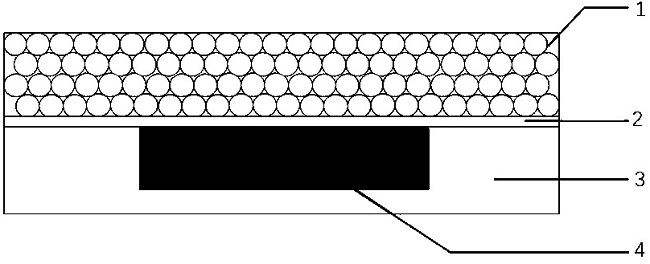

[0039] This embodiment provides a method for preparing a long-lasting composite structural color anti-counterfeiting film, such as figure 1 As shown, its structure includes: epoxy resin inverse opal structure 1; epoxy resin transparent layer 2; epoxy resin film 3 doped with carbon black; epoxy resin pattern 4 doped with long persistence material.

[0040] The preparation method of the structural color thin film includes:

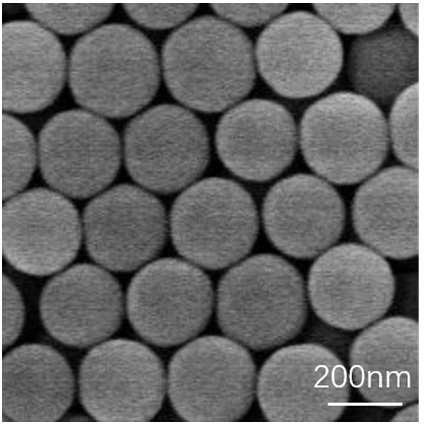

[0041] (1) Firstly, SiO with particle sizes of 210nm, 240nm and 270nm 2 The nano-microspheres and absolute ethanol are respectively prepared into a dispersion with a mass fraction of 7wt% and placed in a 20ml beaker for subsequent use;

[0042] (2) Wipe the polyethylene sheet clean with ethanol and dry it, clamp it on a pulling instrument and pull it at a speed of 5 μm / s, and finally a layer of SiO2 is attached to the surface of the sheet 2 Photonic crystal structure composed of nano-microspheres;

[0043] (3) get epoxy resin A liquid: B liquid=3:1 mass r...

Embodiment 1

[0049] The present embodiment provides a composite anti-counterfeiting structured color film based on photonic bandgap matching, its structure is consistent with embodiment 1, and its preparation method comprises:

[0050] (1) Take the prepared SiO with particle size of 210nm and 240nm 2 The nanometer microspheres and absolute ethanol are prepared respectively into a dispersion solution with a mass fraction of 7wt% and placed in a 20ml beaker for subsequent use;

[0051] (2) Wipe the polyethylene sheet clean with ethanol and dry it, clamp it on a pulling instrument and pull it at a speed of 5 μm / s, and finally a layer of SiO2 is attached to the surface of the sheet 2 Photonic crystal structure composed of nano-microspheres;

[0052] (3) get epoxy resin A liquid: B liquid=3:1 mass ratio and prepare pre-gel;

[0053] (4) Mix the epoxy resin pregel and ethanol evenly in a volume ratio of 1:1 and drop it onto the photonic crystal structure on the polyethylene sheet, and place it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com