Aluminum deoxidized steel with tellurium-sulfur synergistic treatment and its preparation method and application

A technology of synergistic processing and aluminum deoxidation, applied in the manufacture of converters, etc., can solve the problem of not considering the high melting point and achieve good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

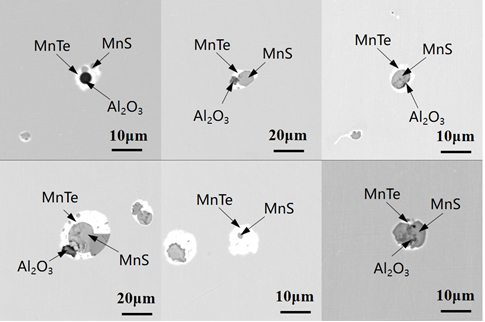

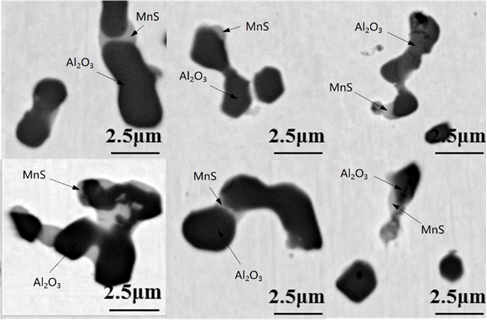

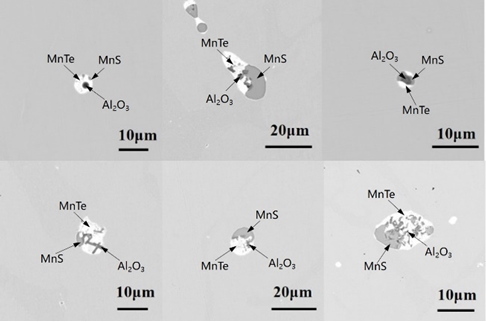

Image

Examples

preparation example Construction

[0056] The present application also provides a method for preparing the aluminum-deoxidized steel with tellurium-sulfur synergistic treatment, including:

[0057] The molten iron is smelted in a converter, and deoxidation and alloying are carried out during the tapping process;

[0058] Perform LF refining, add sulfur-iron alloy and tellurium wire, and then continuously cast to obtain the aluminum deoxidized steel with the tellurium-sulfur synergistic treatment.

[0059] In an optional embodiment, the molten iron is not subjected to pre-desulfurization treatment before converter smelting;

[0060] The molten iron is not pre-desulfurized to ensure that the molten steel has a higher sulfur content after converter smelting.

[0061] In an optional embodiment, the molten iron is pre-desiliconized and pre-dephosphorized before being smelted in a converter. This operation can reduce the consumption of dephosphorization treatment agent, and control the phosphorus content into the c...

Embodiment 1

[0091] This example provides an aluminum deoxidized steel with tellurium-sulfur synergistic treatment, its main components (wt%) are: C: 0.063%, Al: 0.015%, Si: 0.015%, Mn: 1.2%, S: 0.09%, P: 0.045%, Te: 0.045%, and the rest are Fe and unavoidable impurity elements. Among them, ω[Te] / ω[S]=0.5.

[0092] This embodiment provides a method for preparing aluminum-deoxidized steel with tellurium-sulfur synergistic treatment. The smelting process used in this aluminum deoxidized steel: converter → LF → continuous casting.

[0093] Converter smelting: The molten iron is not pre-desulfurized to ensure a higher sulfur content in the molten steel after converter smelting. The molten iron before entering the converter is pre-desiliconized and then pre-dephosphorized, and the phosphorus content of the molten steel for tapping is 0.045wt%. The molten steel is deoxidized and alloyed by tapping the converter, and the carbon content at the end of the converter is 0.035wt%. Add 3.0kg / t of a...

Embodiment 2

[0097]This example provides an aluminum deoxidized steel with tellurium-sulfur synergistic treatment, its main components (wt%) are: C: 0.063%, Al: 0.015%, Si: 0.015%, Mn: 1.2%, S: 0.09%, P: 0.045%, Te: 0.09%, and the rest are Fe and unavoidable impurity elements. Among them, ω[Te] / ω[S]=1.

[0098] This embodiment provides a method for preparing aluminum-deoxidized steel with tellurium-sulfur synergistic treatment.

[0099] The smelting process used in this aluminum deoxidized steel: converter → LF → continuous casting.

[0100] Converter smelting: The molten iron is not pre-desulfurized to ensure a higher sulfur content in the molten steel after converter smelting. The molten iron before entering the converter is pre-desiliconized and then pre-dephosphorized, and the phosphorus content of the molten steel for tapping is 0.045wt%. The molten steel is deoxidized and alloyed by tapping the converter, and the carbon content is adjusted to 0.035wt% at the end of the converter. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com