Full-automatic intelligent feeding method and system based on big data

A fully automatic, big data technology, applied in manufacturing computing systems, data processing applications, general control systems, etc., can solve the problems of reduced production efficiency, consumption of large manpower and material resources, material faults, etc., to improve production efficiency and save manpower and material resources. , to avoid the effect of untimely feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

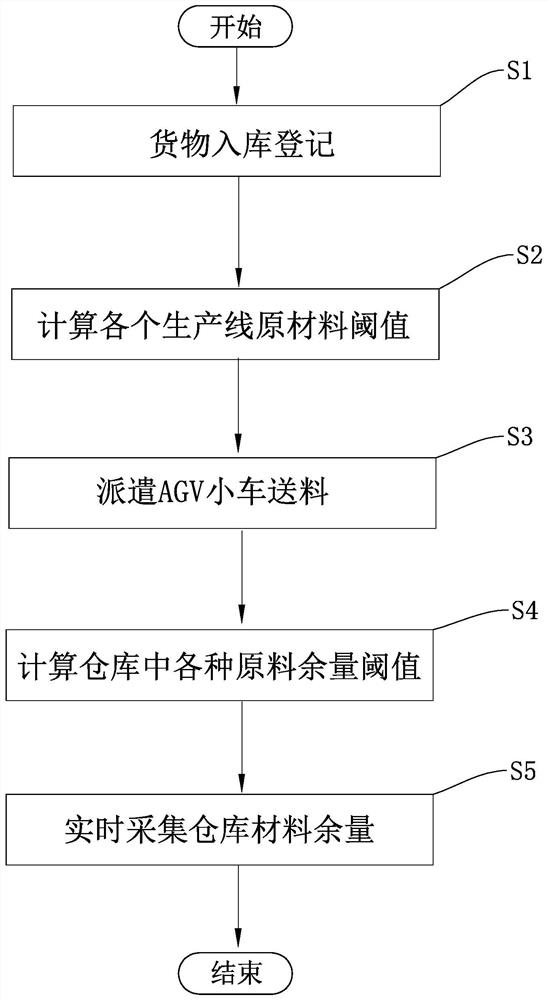

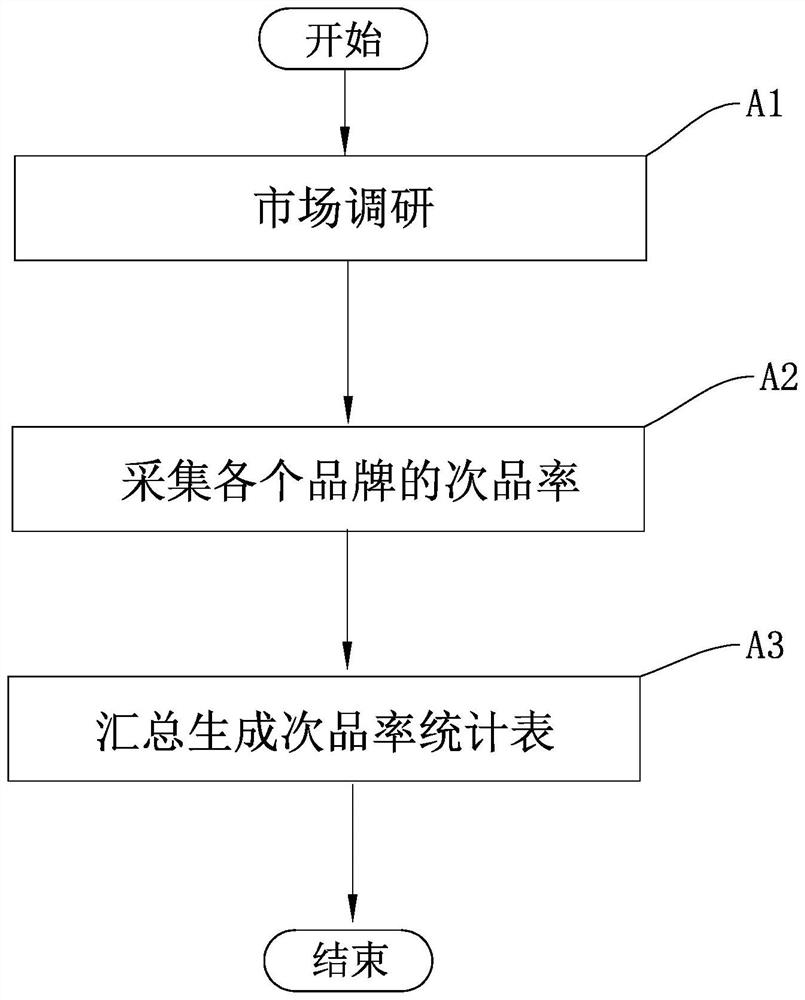

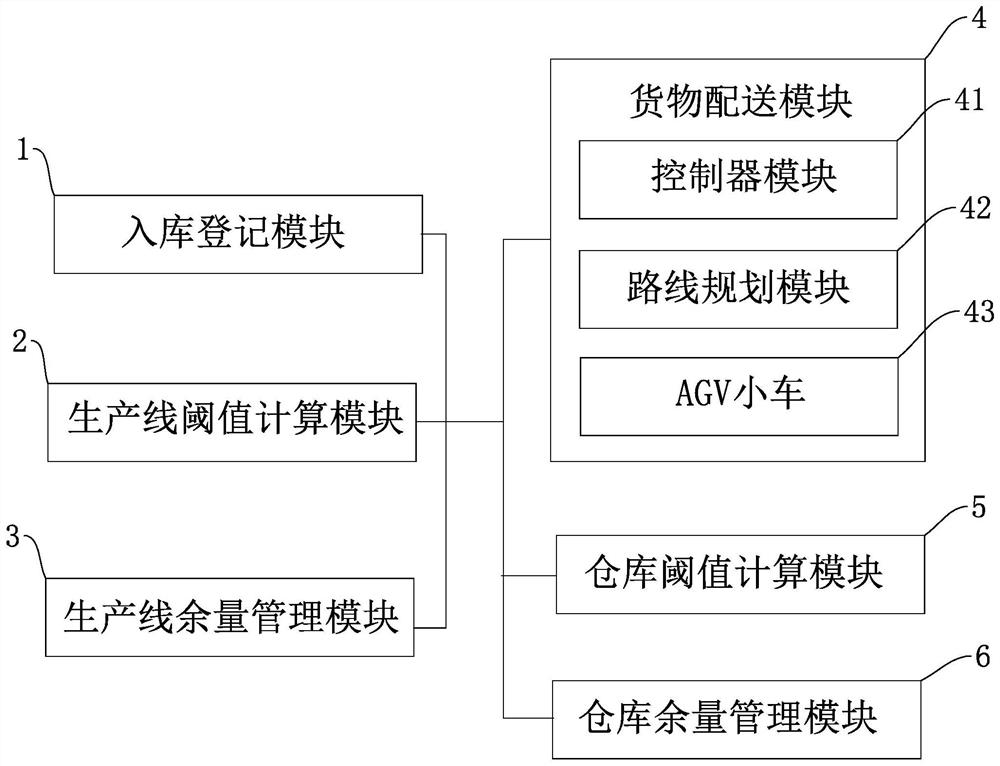

[0053] The following is attached Figure 1-3 The application is described in further detail.

[0054] AGV trolley refers to a transport vehicle equipped with automatic navigation devices such as electromagnetic or optical, capable of driving along a prescribed navigation path, with safety protection and various transfer functions. A truck that does not require a driver in industrial applications is powered by a rechargeable battery. Generally, the computer can be used to control its travel path and behavior, or use the electromagnetic track (electromagnetic path-following system) to set up its travel path. The electromagnetic track is pasted on the floor, and the unmanned van relies on the information brought by the electromagnetic track. To move and act.

[0055] The embodiment of the present application discloses a fully automatic intelligent feeding method based on big data. refer to figure 1 , a fully automatic intelligent feeding method based on big data, comprising t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com