Semiconductor power module packaging structure

A power module and packaging structure technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of complex installation, increased workload, large parasitic capacitance and parasitic inductance, etc., to ensure the working environment , save manpower, improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

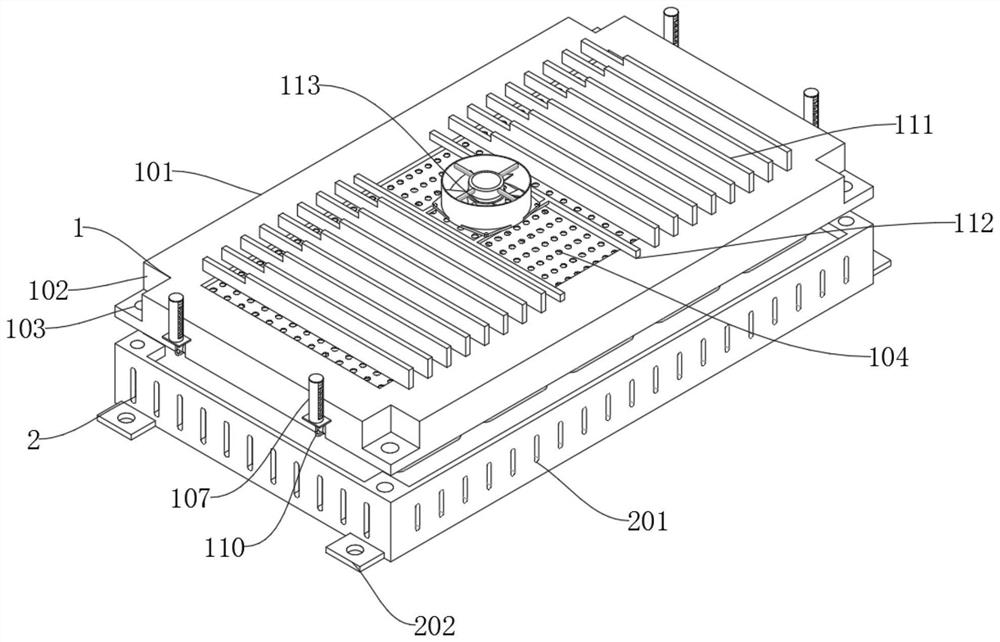

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention provides a technical solution: a semiconductor power module packaging structure, including a mounting mechanism 1 for packaging and a bearing mechanism 2 for carrying the semiconductor. The mounting mechanism 1 includes a cover plate 101, a mounting groove 102, Upper threaded holes 103, four corners on the cover plate 101 are provided with mounting grooves 102, the mounting grooves 102 are provided with upper threaded holes 103, and the upper end surface of the cover plate 101 is provided with a square mounting hole that penetrates up and down. An isolation net 104 is detachably and fixedly installed, and two side plates 106 are arranged on both sides of the cover plate 101, and the side of the cover plate 101 is located below the side plate 106. 105, a fixed cylinder 107 is arranged on the upper end surface of the side plate 106, a spring 108 is installed on the inner si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com