LED structure and manufacturing method thereof

A technology of LED structure and manufacturing method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high manufacturing cost and insufficient luminous brightness, and achieve the effects of reducing dosage, good current blocking effect, and high industrial practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0093] This embodiment provides a method for manufacturing an LED structure, the method comprising:

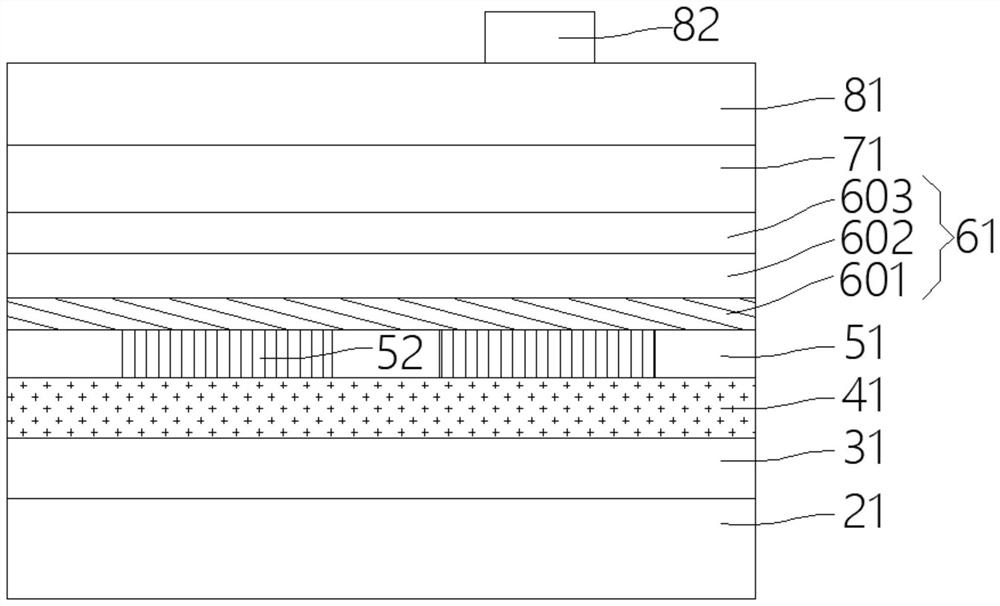

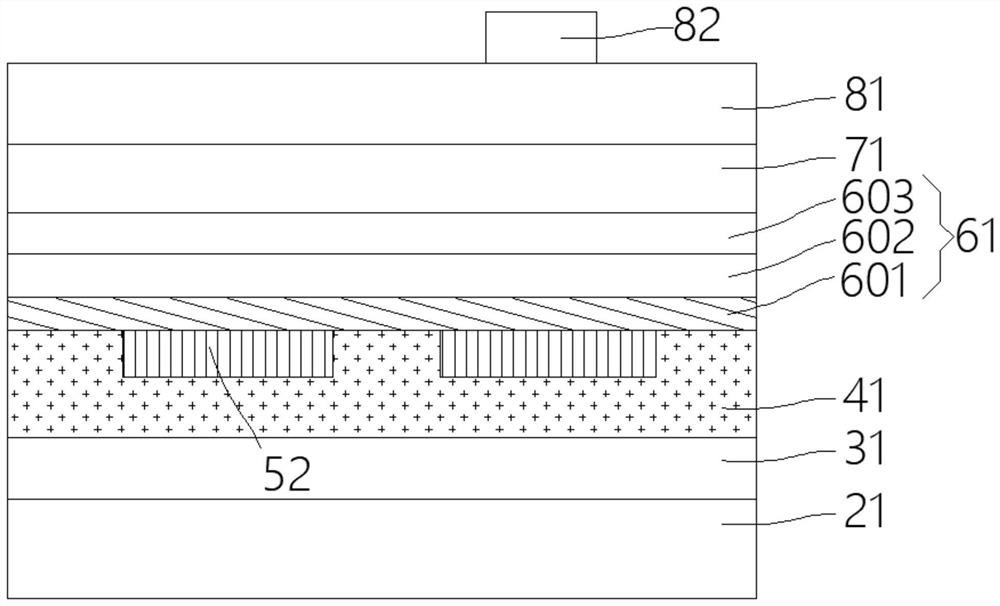

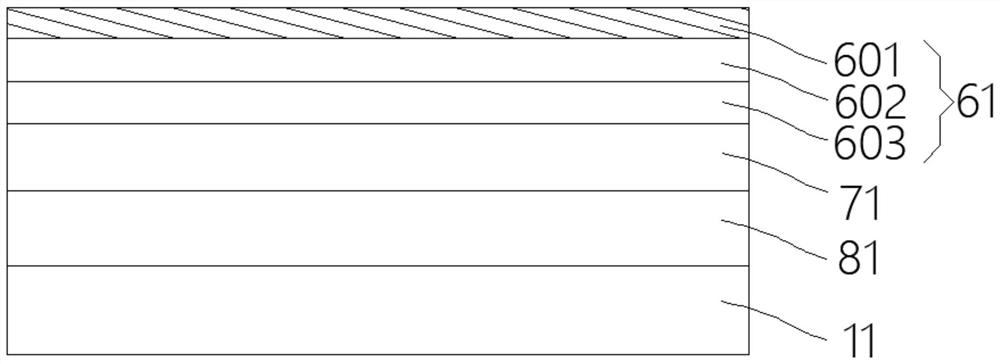

[0094] S1: Provide a semiconductor structure, which includes a substrate layer 11, a first conductivity type semiconductor layer 81, an active layer 71, and a second conductivity type semiconductor layer 61 stacked in sequence, and the second conductivity type semiconductor layer includes a current Extension layer 601, such as image 3 shown;

[0095] Specifically, the substrate layer 11 is an epitaxial substrate, which may be a sapphire substrate, a Si substrate or a SiC substrate. The semiconductor structure may be a material system such as GaN, GaP, AlGaInP, etc., which is not limited here. The second conductivity type semiconductor layer 61 includes a current spreading layer 601 , the current spreading layer 601 may be p-type GaP, and the current spreading layer 601 may further include a transition layer 602 and a barrier layer 603 .

[0096] S2: patterning the current ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com