Composite positive pole piece as well as preparation method and application thereof

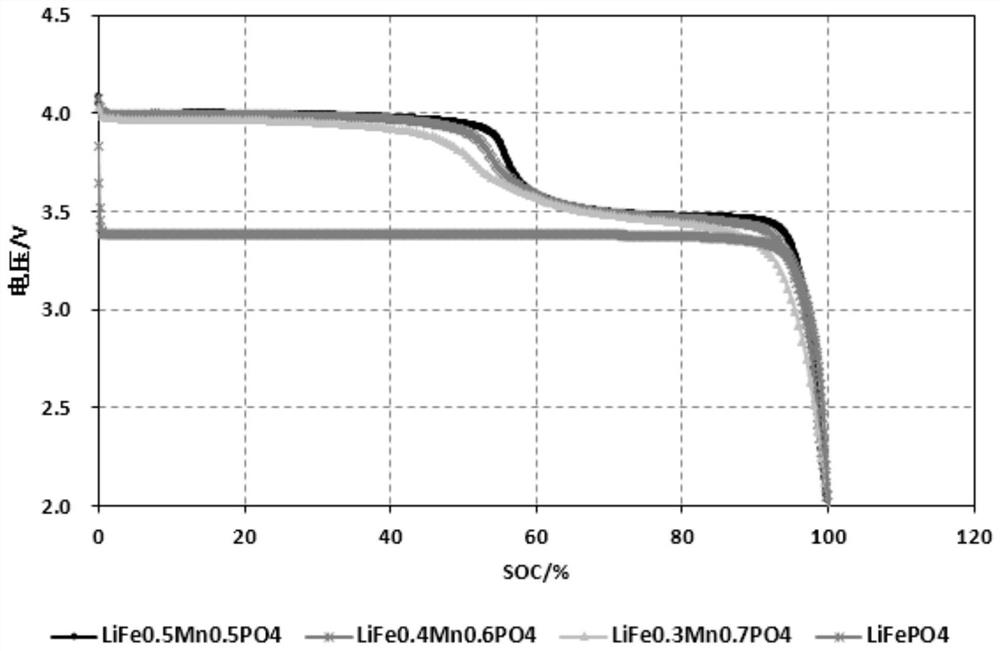

A composite cathode and cathode technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low voltage and energy density, poor conductivity, poor conductivity of lithium manganese iron phosphate, etc. Low temperature performance, the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the composite positive pole piece comprises:

[0040] S1. LiFePO 4 Preparation of slurry

[0041] 9.35g LiFePO 4 After the powder, 0.4g of conductive agent, and 0.25g of binder are mixed evenly, slowly add 12mL of NMP solvent into the mixed powder, stir rapidly at a speed of 750r / min to fully react for 45min, and obtain a stable and uniform black LiFePO 4 slurry.

[0042] S2. LiFePO 4 Preparation of base

[0043] The prepared LiFePO 4 The slurry is uniformly coated on the current collector of the positive electrode, and then dried in an oven at 100°C to form LiFePO 4 grassroots.

[0044] S3. LiFe 0.5 mn 0.5 PO 4 Preparation of slurry

[0045] 9g LiFe 0.5 mn 0.5 PO 4 After the powder, 0.4g of conductive agent, and 0.25g of binder are mixed evenly, slowly add 12mL of NMP solvent into the mixed powder, stir rapidly at a speed of 750r / min to fully react for 45min, and obtain a stable and uniform black LiFe 0.5 mn 0.5 PO 4 slurry. ...

Embodiment 2

[0053] The preparation method of the composite positive pole piece comprises:

[0054] S1. LiFePO 4 Preparation of slurry

[0055] 46.5Kg LiFePO 4 After the powder, 2Kg conductive agent, and 1.5Kg binder are mixed evenly, slowly add NMP solvent into the mixed powder, and after dispersion, a stable and uniform black LiFePO is obtained. 4 The slurry has a viscosity of 5000mPa·s and a solid content of 50%.

[0056] S2. LiFePO 4 Preparation of base

[0057] The prepared LiFePO 4 The slurry is evenly coated on the current collector, and then dried in an oven at 150°C to form LiFePO 4 grassroots.

[0058] S3. LiFe 0.4 mn 0.6 PO4 Preparation of slurry

[0059] 46.5Kg LiFe 0.5 mn 0.5 PO 4 After the powder, 2Kg conductive agent, and 1.5Kg binder are mixed evenly, slowly add NMP solvent into the mixed powder, and after dispersion, a black stable and uniform LiFe 0.4 mn 0.6 PO 4 The slurry has a viscosity of 10000mPa·s and a solid content of 68%.

[0060] S4. LiFe 0.4 m...

Embodiment 3

[0067] The preparation method of the composite positive pole piece comprises:

[0068] S1. LiNi x co y mn z o 2 Preparation of slurry

[0069] 96Kg LiNi x co y mn z o 2 After the powder, 2Kg conductive agent, and 2Kg binder are mixed evenly, slowly add NMP solvent into the mixed powder, and after dispersion, black stable and uniform LiNi is obtained x co y mn z o 2 slurry.

[0070] S2. LiNi x co y mn z o 2 Preparation of base

[0071] The prepared LiNi x co y mn z o 2 The slurry is evenly coated on the current collector, and the coating surface density is 185g / m 2 , and then dried in an oven to form LiNi x co y mn z o 2 grassroots.

[0072] S3. LiFe 0.5 mn 0.5 PO 4 Preparation of slurry

[0073] 96Kg LiFe 0.5 mn 0.5 PO 4 After the powder, 2Kg conductive agent, and 2Kg binder are mixed evenly, slowly add NMP solvent into the mixed powder, and after dispersion, a black stable and uniform LiFe 0.5 mn 0.5 PO 4 slurry.

[0074] S4. LiFe 0.5 mn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com