Sole ejection device capable of recycling EVA raw materials and ejection process

A raw material and process technology, which is applied in the field of shoe sole injection device and injection process, can solve the problems such as the inability to recycle EVA raw materials, and achieve the effects of being beneficial to recycling, improving flame retardancy, and avoiding manual mold taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

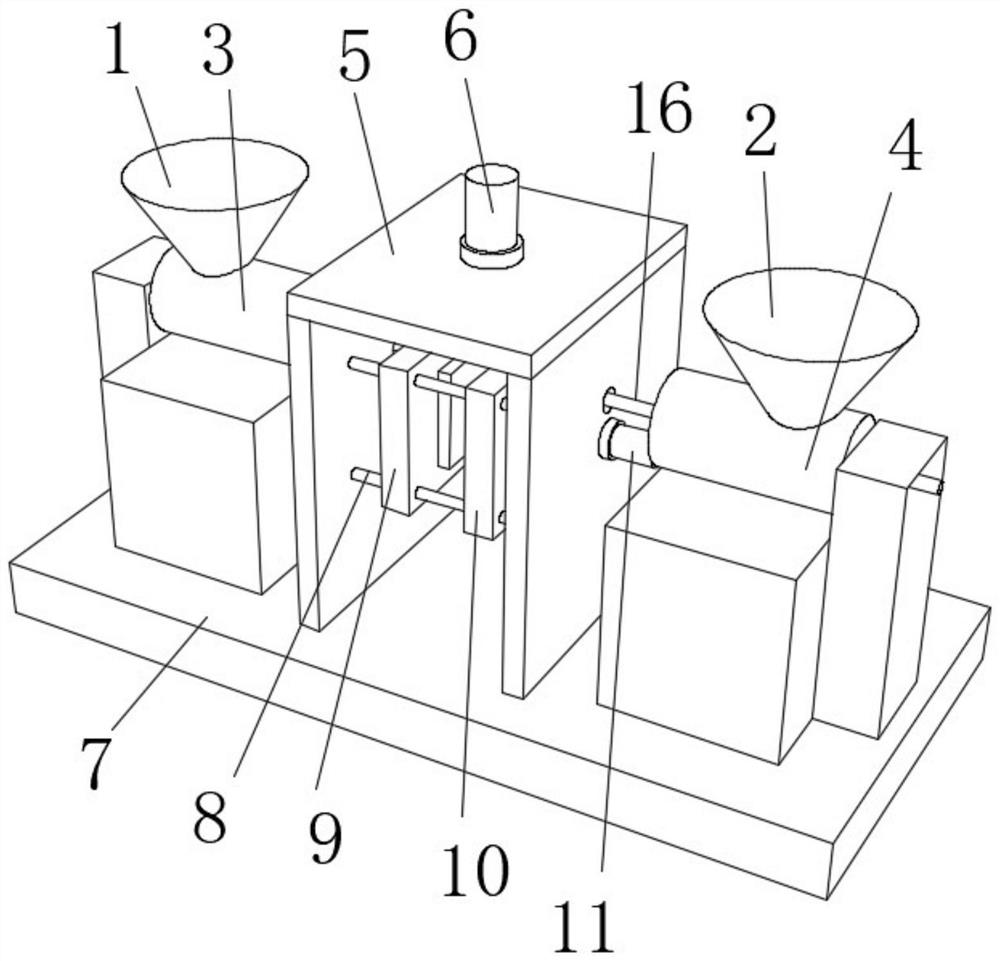

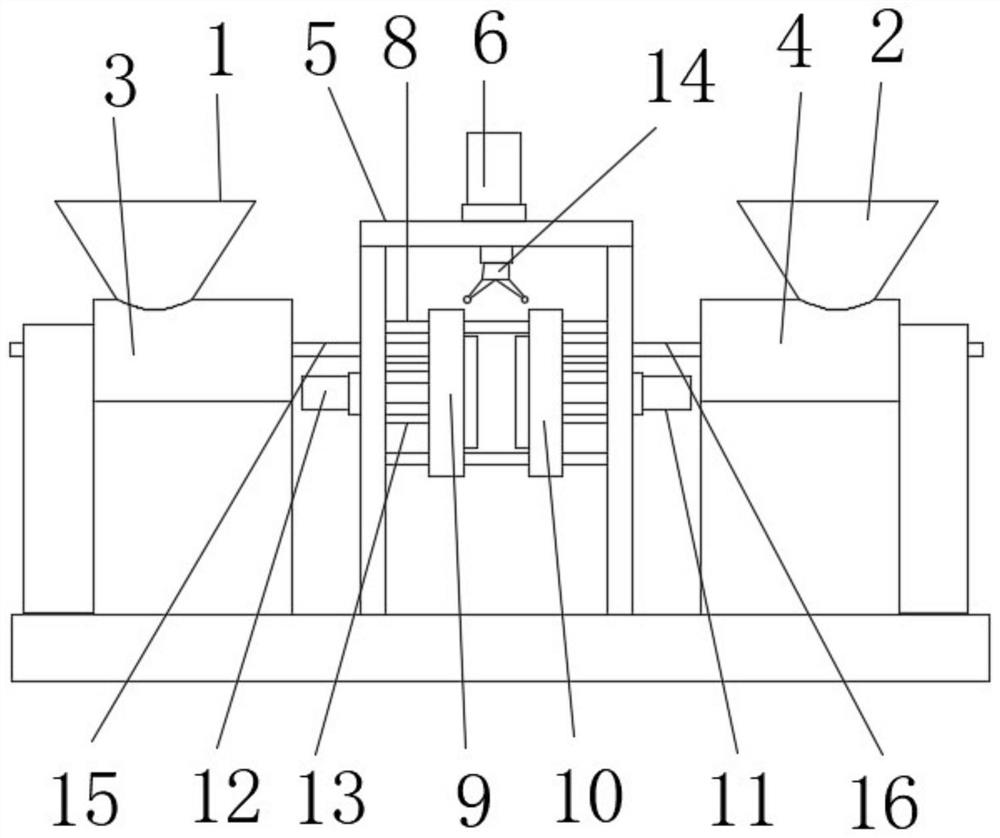

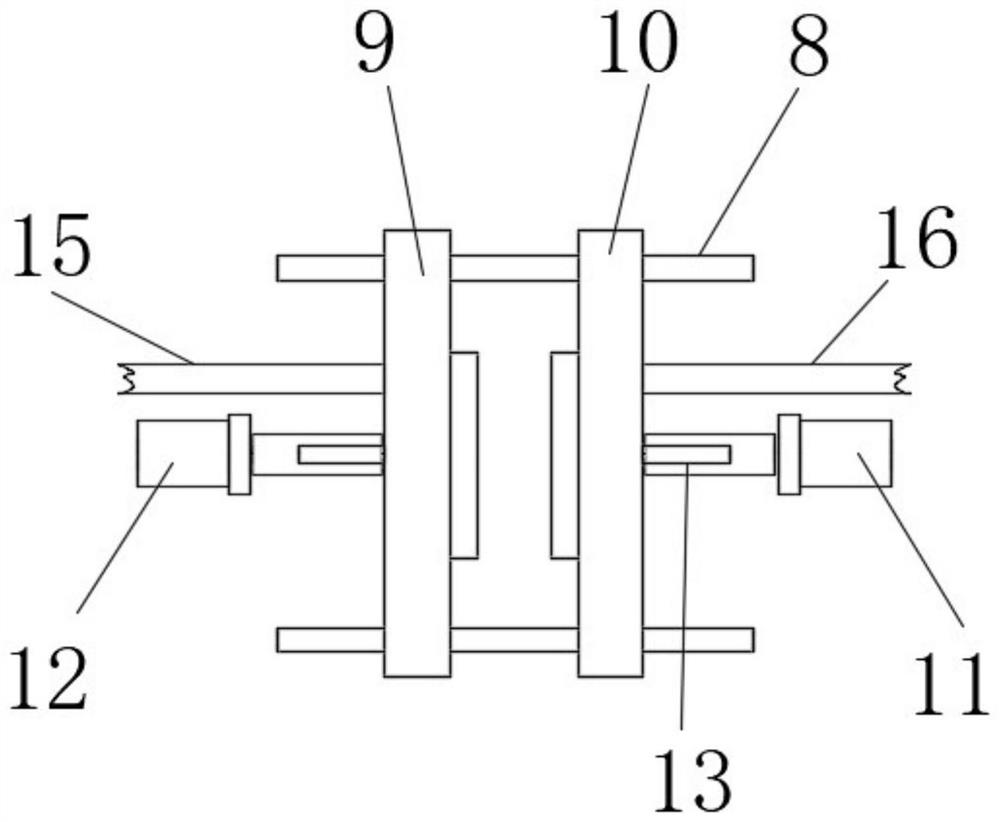

[0034] Such as Figure 1-Figure 4 Shown, the embodiment of the present invention provides the sole injection device of recyclable EVA raw material, comprises workbench 7, the first injection machine 3 and the second injection machine 4, and the top two ends of workbench 7 are respectively connected with the first injection machine 3 and the second injection machine 4. The bottom of the second injection machine 4 and the middle end of the top of the workbench 7 are fixedly connected with the work frame 5, the top middle of the work frame 5 is fixedly connected with the third cylinder 6, and the output end of the third cylinder 6 is fixedly connected with the gripper 14. The clamper 14 can move up and down through the third cylinder 6. The clamper 14 can clamp the semi-finished EVA sole, and place it between the left mold 9 and the right mold 10. After the sole pops up, pass through the third cylinder 6 The gripper 14 is moved downwards so that the soles can be completely droppe...

Embodiment 2

[0039] The embodiment of the present invention provides the injection process of the sole injection device of recyclable EVA raw material, comprising the following steps: clamp the EVA sole semi-finished product by the clamper 14, move the clamper 14 downward by the third cylinder 6, and the clamper 14 Place the EVA sole semi-finished product between the left mold 9 and the right mold 10;

[0040] The first cylinder 12 can drive the left mold 9 to move horizontally, the second cylinder 11 can make the right mold 10 move horizontally, and the left mold 9 and the right mold 10 are combined by the first cylinder 12 and the second cylinder 11, and the left mold 9 and The right mold 10 can clamp the EVA sole semi-finished product;

[0041] Add the shoe sole material in the first injection machine 3 and the second injection machine 4 respectively, the shoe sole material is injected into the left mold 9 by the first injection machine 3, and the shoe sole material is injected into the...

Embodiment 3

[0044] The embodiment of the present invention provides the injection process of the sole injection device of recyclable EVA raw material, comprising the following steps:

[0045] Take the following raw materials in parts by weight: 40-50 parts of ethylene-vinyl acetate copolymer, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 3-5 parts of foaming agent, 1-2 parts of crosslinking agent 3 parts, 2-4 parts of catalyst, 1-3 parts of light stabilizer;

[0046] Pre-mix the above raw materials in the mixer for 5-10 minutes, fully mix and stir with the internal mixer, banbury the tablets, add sulfur and foam, and the foamed EVA sheets must be fully cooled and shrunk, and the skin should be removed with a peeler , cut strips by a strip cutter, and the length of the cut strips is greater than the length of the left mold 9 or the right mold 10 to obtain a semi-finished EVA shoe sole.

[0047] Take the following raw materials in parts by weight: 15-30 parts of polyurethane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com