Method and device for in-situ remediation of groundwater pollution by electrically driven biological PRB (permeable reactive barrier)

A groundwater pollution and in-situ remediation technology, which is applied in biological water/sewage treatment, water pollutants, electrochemical and biological combined treatment, etc., can solve problems such as limited remediation effect, limited effect of groundwater pollution remediation, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

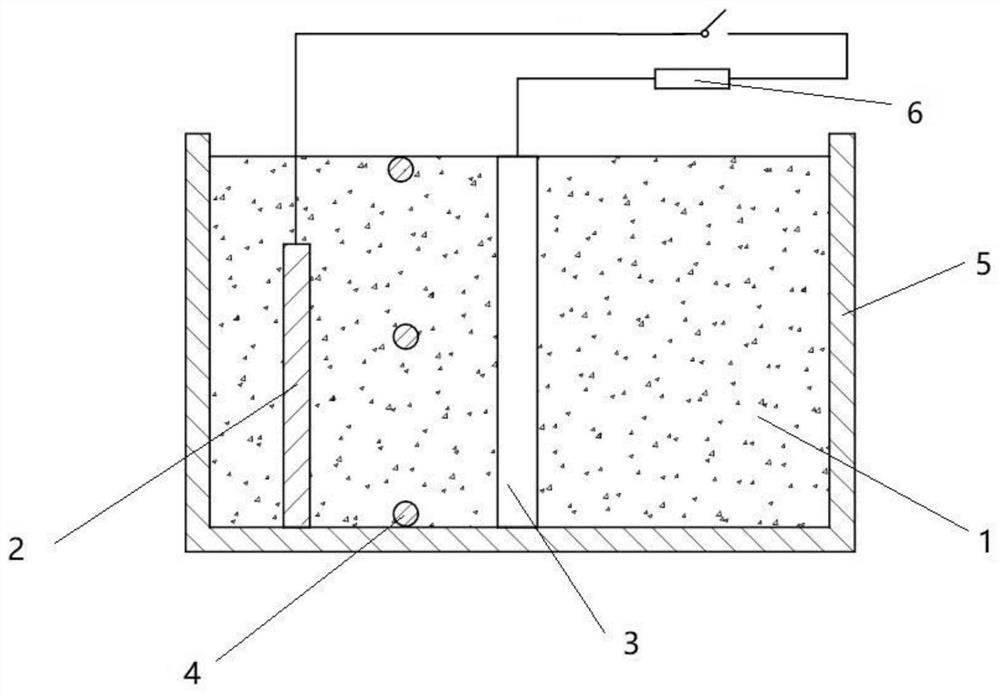

[0043] Such as figure 1 As shown, the permeable reaction wall 1 is set as a cylinder, and its volume is Φ75 mm × 100 mm. The cylindrical permeable reaction wall 1 is filled with a mixed filler of 140g of conductive carbon material and 28g of zero-valent iron material, wherein the mass ratio of conductive carbon material and zero-valent iron material is 20%. The conductive carbon material uses graphite particles with a particle size of 2-4mm and a density of 2.1-2.3g cm-3; the zero-valent iron material uses zero-valent iron particles with a particle size of 2mm and a density of 3.5-4.0g cm-3 . A carbon rod with a volume of Φ5 mm × 100 mm is inserted into the permeable reaction wall 1 as the anode 2, and the permeable reaction wall 1, anode 2 and microorganisms together constitute the anode area of the biological PRB.

[0044] An air cathode was inserted in the center of the bio-PRB anode area as the cathode 3, the volume of the air cathode was Φ20 mm × 100 mm, and platinum ...

Embodiment 2

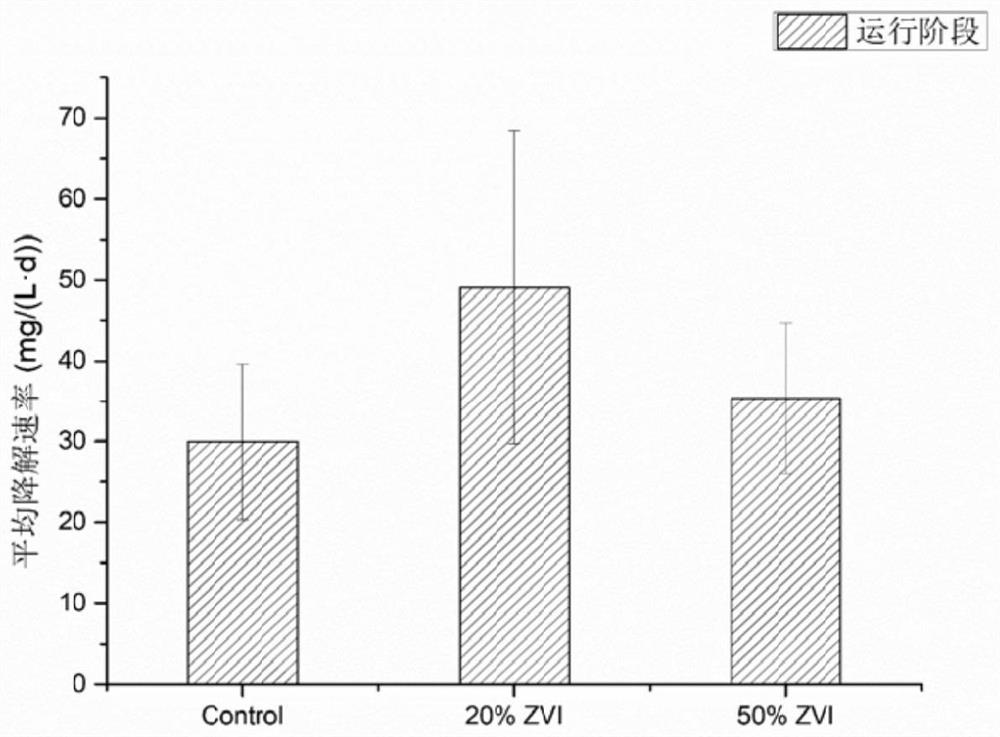

[0048] The filler of the permeable reaction wall 1 is: a mixed filler of 140g of conductive carbon material and 70g of zero-valent iron material, the mass ratio of conductive carbon material and zero-valent iron material is 50%, and the rest of the components are the same as in Example 1.

[0049] In the control group, the filler of the permeable reaction wall 1 is 140g of conductive carbon material without zero-valent iron material, and the rest is the same as that of Example 1.

[0050] The device of the present invention can adjust the shape, structure and position of the permeable reaction wall 1, the anode 2, the cathode 3, the water-conducting wall 4, the external circuit element 6 and the final reactor 5 according to the environment.

Embodiment 3

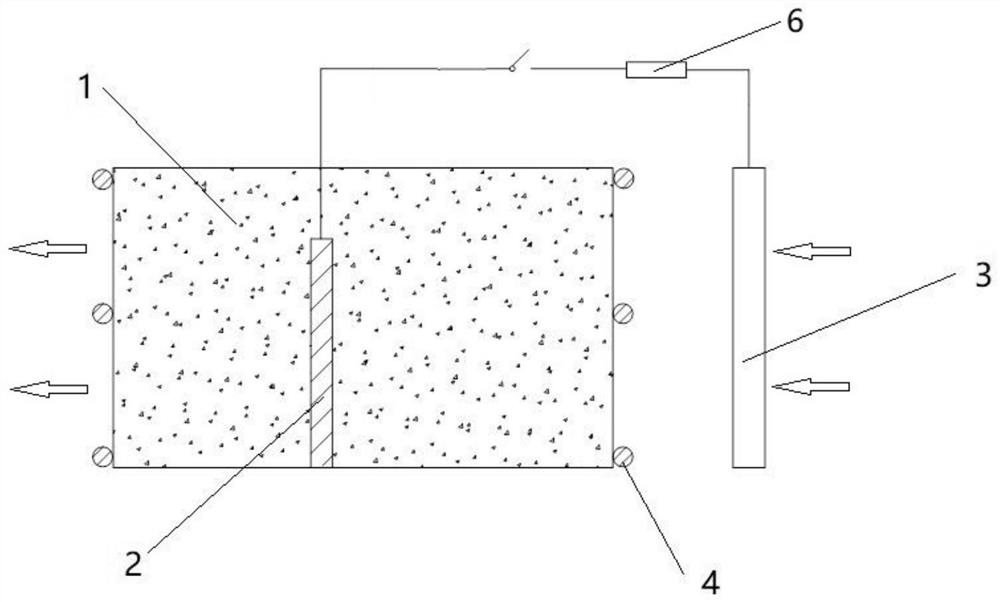

[0052] As an embodiment of the device of the present invention, such as figure 2 As shown, the anode 2 is inserted into the permeable reaction wall 1, and the permeable reaction wall 1, anode 2 and microorganisms together constitute the anode area of the biological PRB. The cathode 3 is installed at the water inlet end of the bio-PRB anode area, and a water-conducting wall 4 is set between the bio-PRB anode area and the cathode 3, and a water-conducting wall 4 is also provided at the water outlet of the bio-PRB anode area. The external circuit element 6 is a power supply; the cathode 3 is connected to the negative electrode of the external circuit element 6 through a copper wire, and the anode area of the biological PRB is connected to the positive electrode of the external circuit element 6 through an anode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com