Self-compacting C70 concrete and preparation method thereof

A concrete and self-compacting technology, applied in the field of concrete, can solve the problems of poor durability of self-compacting concrete, easy cracks in self-compacting concrete, and easy moisture erosion of concrete, etc., and achieve good retarding effect, not easy to water erosion, and good moisturizing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0062] A self-compacting C70 concrete made from concrete mixes.

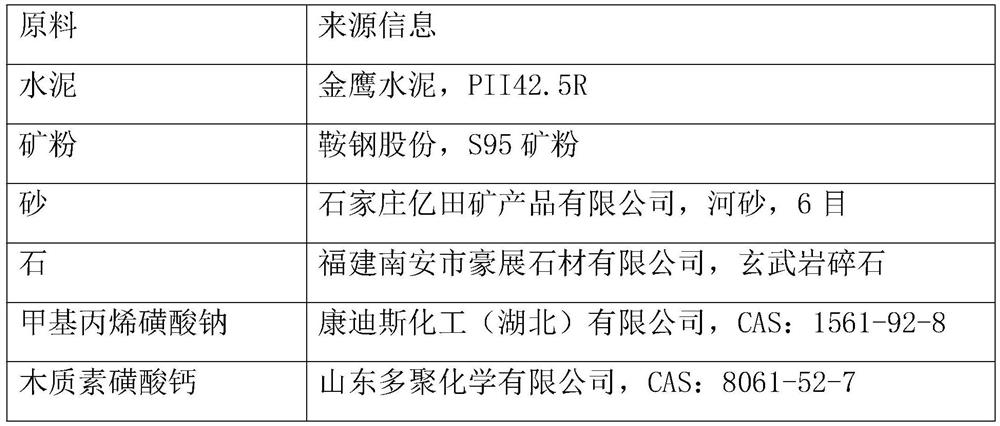

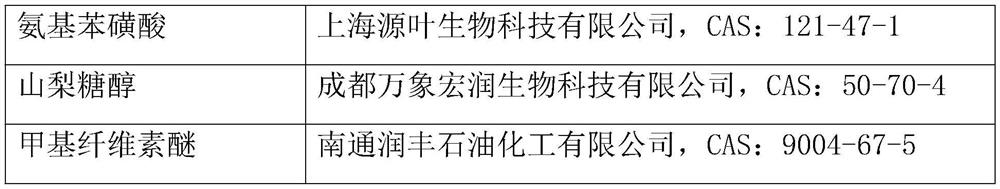

[0063] Concrete mixes consist of the following components:

[0064] Water, cement, mineral powder, sand, stone, sodium methacrylate, calcium lignosulfonate, aminobenzenesulfonic acid, sorbitol, methyl cellulose ether.

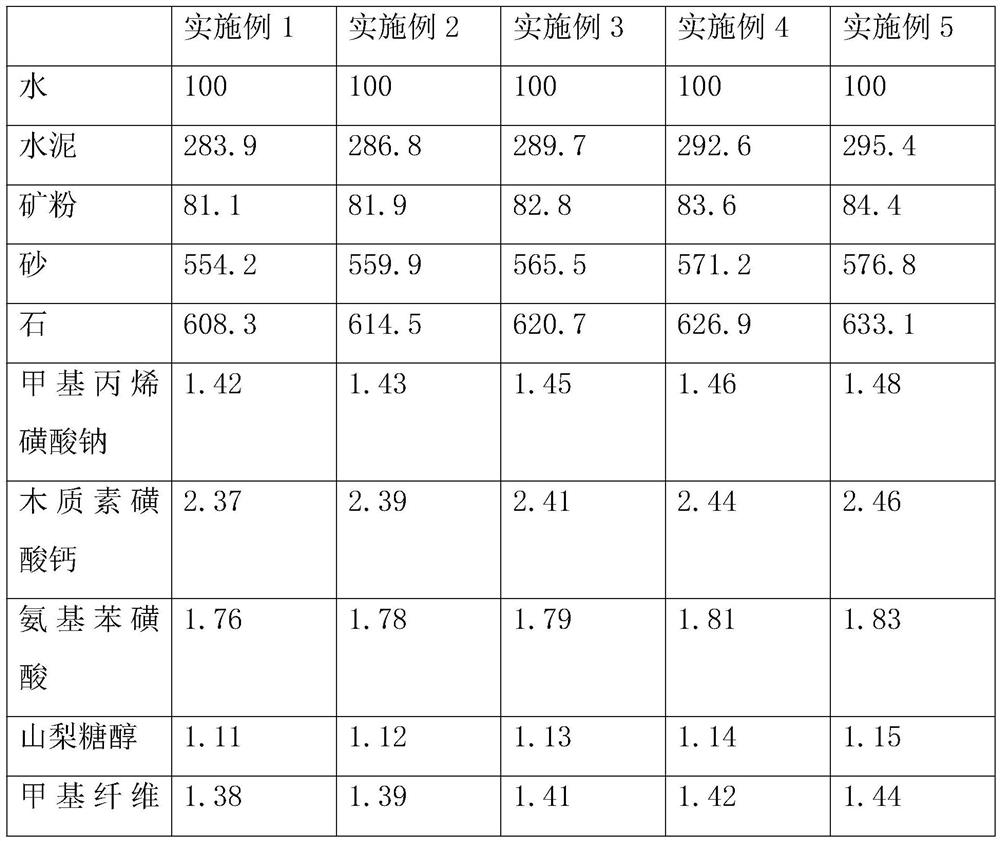

[0065] In Examples 1-5, see Table 2 for the specific input amount (unit: kg) of each component.

[0066] Table 2

[0067]

[0068]

[0069] In Examples 1-5, the average particle size of the stone is 10 mm, and the maximum particle size is ≤20 mm.

[0070] In embodiment 1-5, the preparation method of self-compacting C70 concrete is as follows:

[0071] Step 1), put cement, mineral powder, sodium methacrylsulfonate, calcium lignosulfonate, aminobenzenesulfonic acid, sorbitol, and methyl cellulose ether into the stirring tank at a speed of 120r / min and stir for 10min. Mix evenly to obtain a premix;

[0072] Step 2), put sand and stone into the premix, rotate at 60r / min, stir for 5min, and...

Embodiment 6

[0076] A self-compacting C70 concrete, compared with Example 3, the only difference is:

[0077] The average particle size of stone is 15mm, and the maximum particle size is ≤20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com