Slow-release antibacterial electrostatic spinning nanofiber and preparation method thereof

An electrospinning and nanofiber technology, which is applied in the direction of electrospinning, spinning solution preparation, fiber treatment, etc., can solve the problems of food quality, high active ingredients of essential oils, and inability to prolong the shelf life of food, and achieve the goal of reducing emulsifiers Effects of using and avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

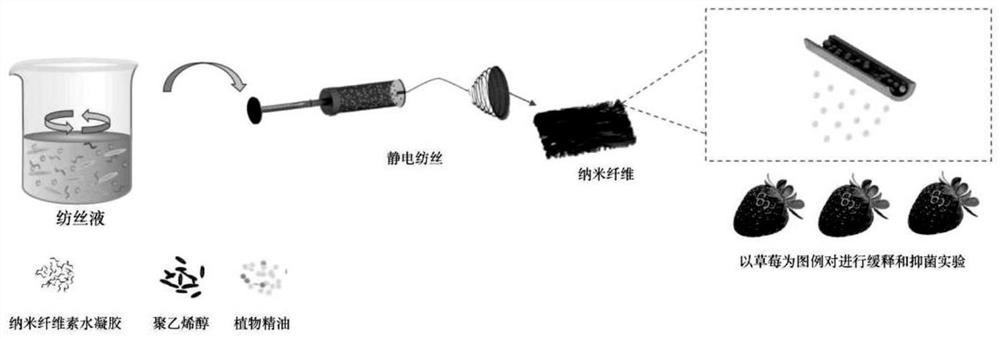

[0029] (1) Preparation of spinning solution

[0030] The mass ratio of 1wt% nanocellulose airgel and 6wt% polyvinyl alcohol aqueous solution obtained by TEMPO oxidation through high-pressure homogenization is 3:4, and the proportion of thyme essential oil (plant essential oil) accounting for the mass fraction of spinning solution is 4%. Disperse completely evenly under 1000rpm / min high-speed shearing machine for 10min, and then use a centrifuge at 6000rpm / min to defoam for 20min to remove air bubbles in the solution to obtain spinning solution. The preparation process is as follows: figure 1 ;

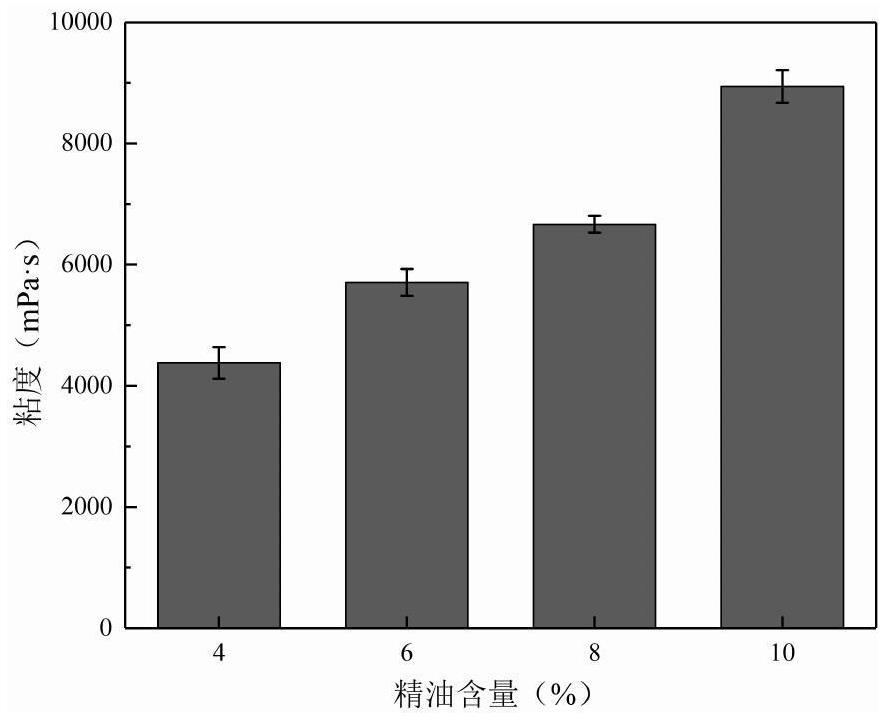

[0031] (2) Physical performance test of spinning solution

[0032] The viscosity, electrical conductivity and surface tension of the spinning solution were tested, and the results are shown in Figure 3(a), Figure 3(b), and Figure 3(c);

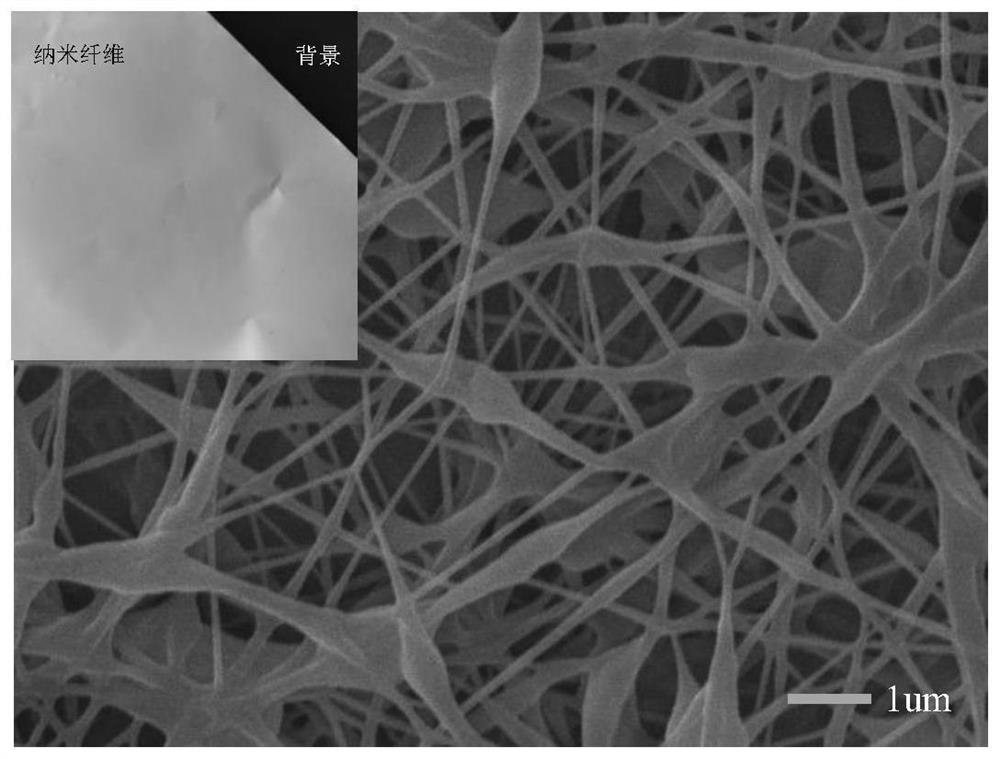

[0033] (3) Set the electrospinning process parameters and prepare nanofibers

[0034] The spinning voltage is 18kV, the injection speed of the spin...

Embodiment 2

[0038] (1) Preparation of spinning solution

[0039] The mass ratio of 1wt% nanocellulose airgel to 6wt% polyvinyl alcohol aqueous solution obtained by TEMPO oxidation through high-pressure homogenization is 3:4, and the mass fraction of thyme essential oil (thyme essential oil for plant essential oil) in the spinning solution is 6 % mixed in a ratio of 1000rpm / min high-speed shearing machine for 10min to make it completely evenly dispersed, and then use a centrifuge at 6000rpm / min to defoam for 20min to remove the bubbles in the solution to obtain a spinning solution, such as figure 1 ;

[0040] (2) Physical performance test of spinning solution

[0041] The viscosity, electrical conductivity and surface tension of the spinning solution were tested, and the results are shown in Figure 3(a), Figure 3(b), and Figure 3(c);

[0042] (3) Set the electrospinning process parameters and prepare nanofibers

[0043] The spinning voltage is 18kV, the injection speed of the spinning s...

Embodiment 3

[0047] (1) Preparation of spinning solution

[0048] The mass ratio of 1wt% nanocellulose airgel to 6wt% polyvinyl alcohol aqueous solution is 3:4 after high-pressure homogenization by TEMPO oxidation, and the mass fraction of thyme essential oil (thyme essential oil for plant essential oil) in the spinning solution is 8 % mixed in a ratio of 1000rpm / min high-speed shearing machine for 10min to make it completely evenly dispersed, and then use a centrifuge at 6000rpm / min to defoam for 20min to remove the bubbles in the solution to obtain a spinning solution, such as figure 1 ;

[0049] (2) Physical performance test of spinning solution

[0050] The viscosity, electrical conductivity and surface tension of the spinning solution were tested, and the results are shown in Figure 3(a), Figure 3(b), and Figure 3(c);

[0051] (3) Set the electrospinning process parameters and prepare nanofibers

[0052] The spinning voltage is 18kV, the injection speed of the spinning solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com