Negative pressure exhaust system for garbage station

A technology of garbage station and negative pressure fan, which is applied in sanitary equipment for toilets, dispersed particle filtration, gas treatment, etc. It can solve problems such as inability to spray, bacteria breeding in garbage, and staff slipping during water stain residence time. Shorten the residence time, accelerate the drying speed, and have good antibacterial and deodorizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

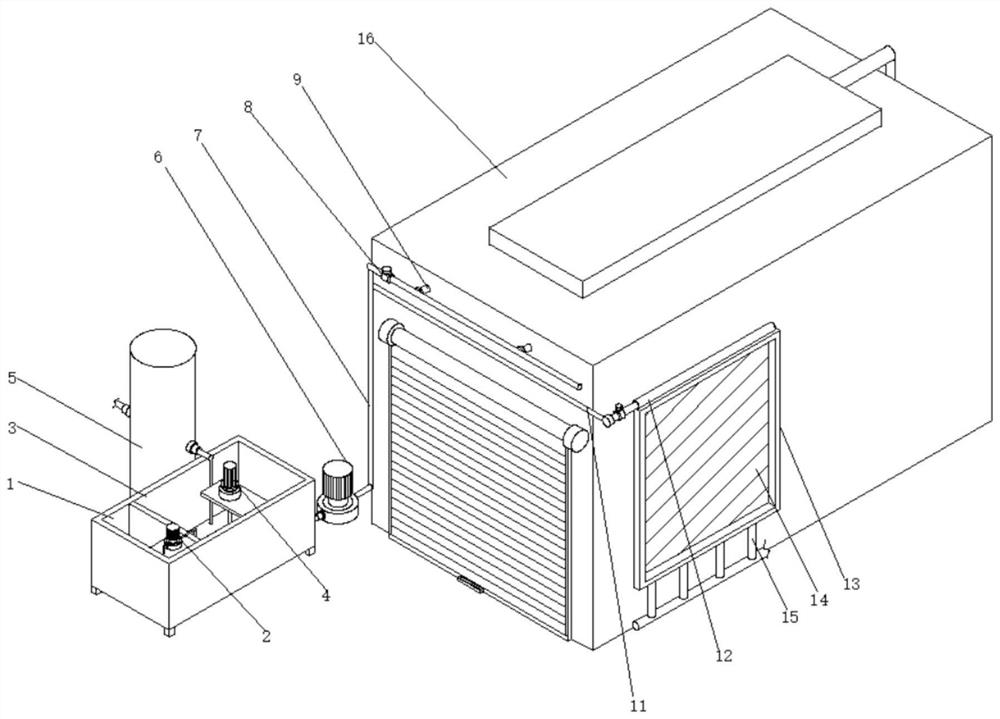

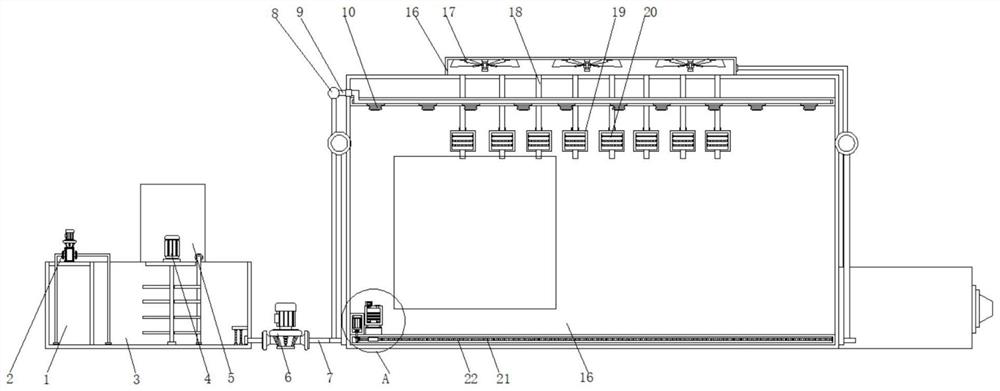

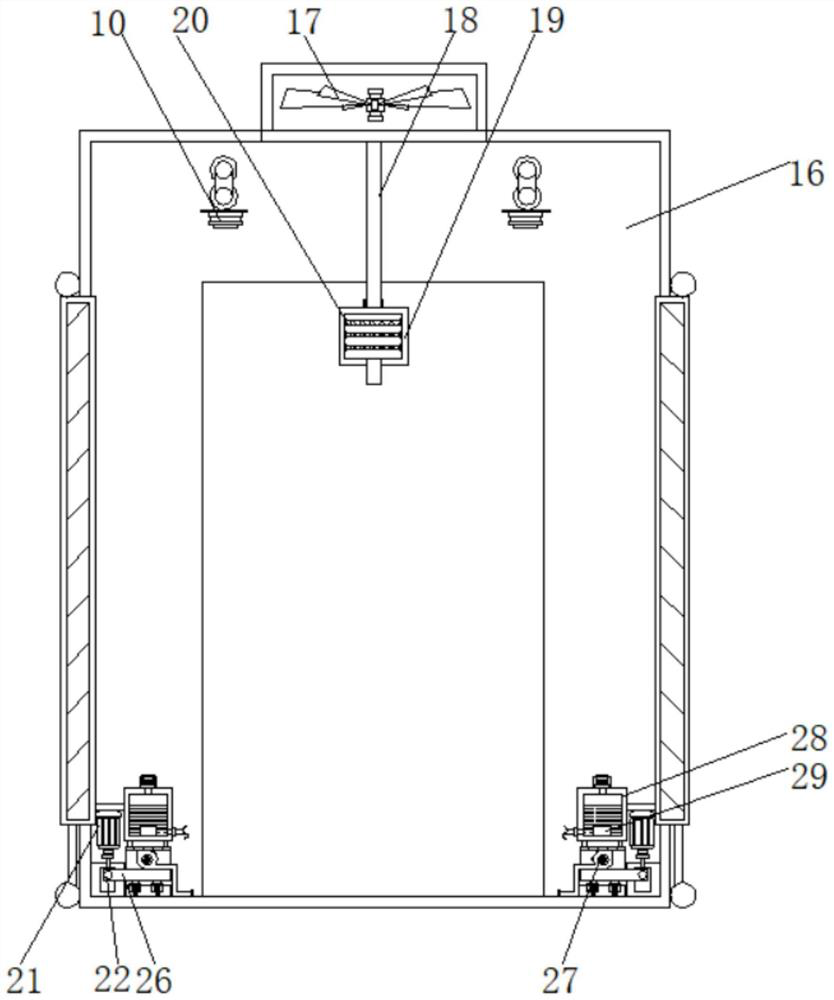

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0028] The embodiments of the present invention will be described below according to the overall structure of the present invention.

[0029] see Figure 1-6, a negative pressure exhaust system for a garbage station, comprising a raw liquid bin 1, a metering pump 2 is arranged on the top of the raw liquid bin 1, and a mixing bin 3 is arranged on one side of the raw liquid bin 1, between the raw liquid bin 1 and the mixing bin 3 A partition is provided, and a filter screen is provided inside the mixing chamber 3, and the number of the filter screens is two groups, and the two groups of filter screens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com