A dosing device and dosing method for an oil production well group

A chemical dosing device and technology for oil production wells, applied in chemical instruments and methods, earthwork drilling, transportation and packaging, etc., can solve the problems of chemical waste, large consumption of chemical agents, wall hanging of chemicals, etc., to avoid waste of chemicals, The dosage is highly controllable and the effect of improving the efficacy of the drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

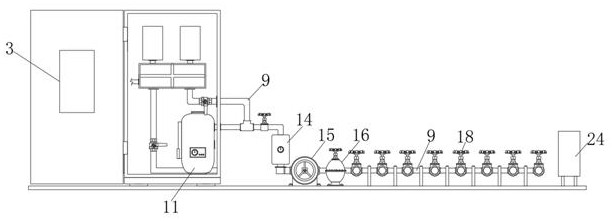

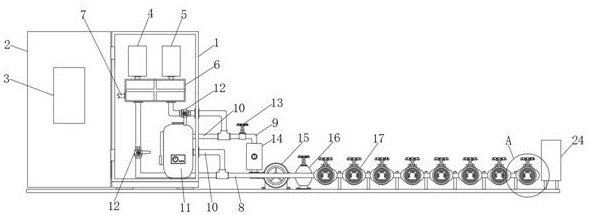

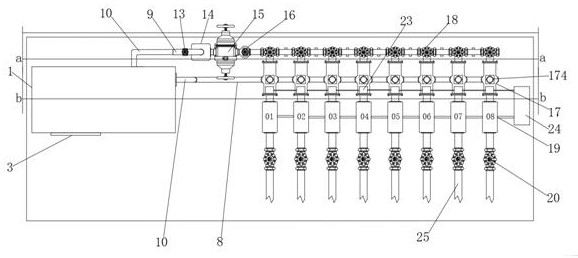

[0058] Such as Figure 1-2 , Figure 7 and Figure 9 As shown, a dosing device for an oil production well group, a dosing device for an oil production well group, including a first box body 1, a box door 2, a control panel 3, and a thickening agent box 4 , descaling agent kit 5, water pipe 7, ball valve 12, pressure detector 14, pipe wall thickness detection sensor 19, fluid velocity detection sensor 23, second casing 24 and crude oil pipeline 25.

[0059] On the inner wall of one side of the first box body 1, a thickening agent cartridge and a descaling agent cartridge 5 are symmetrically fixed by bolts, and a mixing mechanism 6 is communicated with the bottom of the thickening agent cartridge 4 and the descaling agent cartridge 5, wherein, The mixing mechanism 6 includes a first housing 601 and a partition 602. The partition 602 divides the first housing 601 into two halves, and a first The drug guide tube 8, the second drug guide tube 9 is installed at the bottom of the ...

Embodiment 2

[0068] Such as Figure 5 As shown, the drug discharge mechanism 15 also includes a rocking wheel 152, a first threaded rod 153, a push block 154 and a diaphragm. The rocking wheels 152 are symmetrically installed on both sides of the second housing 151, and are located at one end of the rocking wheel 152 and the second The first threaded rod 153 in the housing 151 is connected, and the second housing 151 is slidably connected with a push block 154, and an arc-shaped rubber plate 156 is installed on one side of the push block 154, and the arc-shaped rubber plate 156 and the push block A spring 155 is installed on the opposite surface of 154 , and a diaphragm is installed on the opposite surface of the two arc-shaped rubber plates 156 inside the second housing 151 .

[0069] Such as Figure 6 As shown, the liquid inlet and outlet control mechanism 16 also includes a second threaded rod 163, a placement groove 167, a fourth cock valve 162, a block 164, a vent 165 and a medicine ...

Embodiment 3

[0079] Such as Figure 1-3 , Figure 5 and Figure 6 As shown in the figure, the dosing device used in the oil production well group precisely dispenses the medicine.

[0080] The system modules used in the dosing device of the oil production well group are as follows: Figure 11 As shown, the functions of each module are: the liquid flow rate detection module is used to detect the flow rate value of oil in each pipeline in the oil production well group, which is realized by the fluid flow rate detection sensor 23;

[0081] The pipe wall thickness detection module is used to detect the pipe wall thickness value of each pipeline in the oil production well group, which is realized by the pipe wall thickness detection sensor 19;

[0082] The data acquisition and processing module is used to store the flow rate data value of oil flowing in the pipeline under constant temperature and pressure and the value of the wall thickness of the oil pipeline when it leaves the factory. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com