Nano material for realizing hydrophobic and anti-fogging properties of glasses

A nano-material, hydrophobic technology, applied in glasses/goggles, other chemical processes, instruments, etc., can solve problems such as poor experience, shedding damage, blurred vision, etc., to ensure anti-fog effect, easy to replace and use, improve The effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

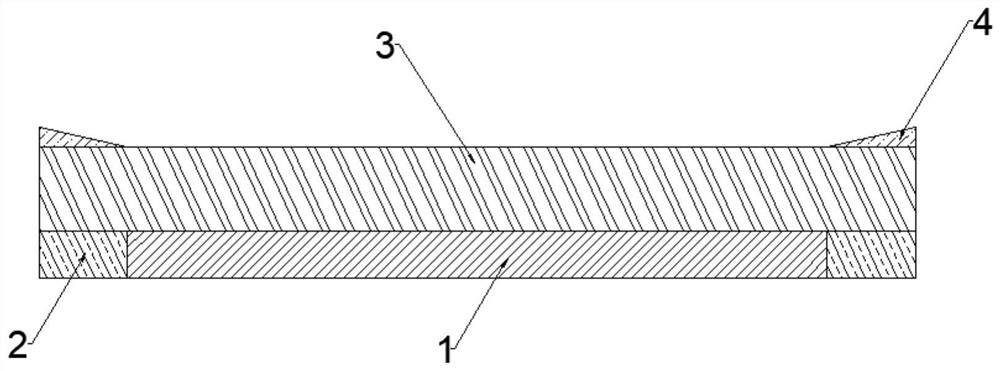

[0033] A nano-material for hydrophobic and anti-fogging of glasses, comprising an inner coating 1, an inner edge layer 2, and an anti-fog coating 3, and the anti-fog coating 3 is covered on the outside of the inner layer 1 and the outer layer 2;

[0034] The composition of inner coating 1 comprises sodium stearate;

[0035] The composition of inner edge layer 2 comprises konjac gum;

[0036] Anti-fog coating 3 comprises the following components by weight percentage:

[0037] 15% titanium dioxide;

[0038] 8% excipients;

[0039] The remainder of the solvent;

[0040] Excipients include silicon nitride;

[0041] Solvents include water and polyethylene glycols.

[0042] The inner coating 1 and the inner edge layer 2 are partially overlapped or connected.

[0043] Titanium dioxide is processed as follows: titanium dioxide is first added to the lye, stirred evenly, heated to 130°C for reaction, the filter residue is taken, washed, dried, and crushed; then sodium dodecylsulfo...

Embodiment 2

[0055] A nano-material for hydrophobic and anti-fogging of glasses, comprising an inner coating 1, an inner edge layer 2, and an anti-fog coating 3, and the anti-fog coating 3 is covered on the outside of the inner layer 1 and the outer layer 2;

[0056] The composition of inner coating 1 comprises sodium stearate;

[0057] The composition of inner edge layer 2 comprises konjac gum;

[0058] Anti-fog coating 3 comprises the following components by weight percentage:

[0059] 32% titanium dioxide;

[0060] 13% excipients;

[0061] The remainder of the solvent;

[0062] Excipients include silicon nitride;

[0063] Solvents include water and polyethylene glycols.

[0064] The inner coating 1 and the inner edge layer 2 are partially overlapped or connected.

[0065] Titanium dioxide is processed as follows: titanium dioxide is first added to the lye, stirred evenly, heated to 160°C for reaction, the filter residue is taken, washed, dried, and crushed; then sodium dodecylsulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com