Device and method of laser compression bonding for semiconductor chip

A semiconductor and chip technology, applied in laser compression bonding equipment and fields of semiconductor chips, can solve problems such as thermal stress that is not easy to solve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

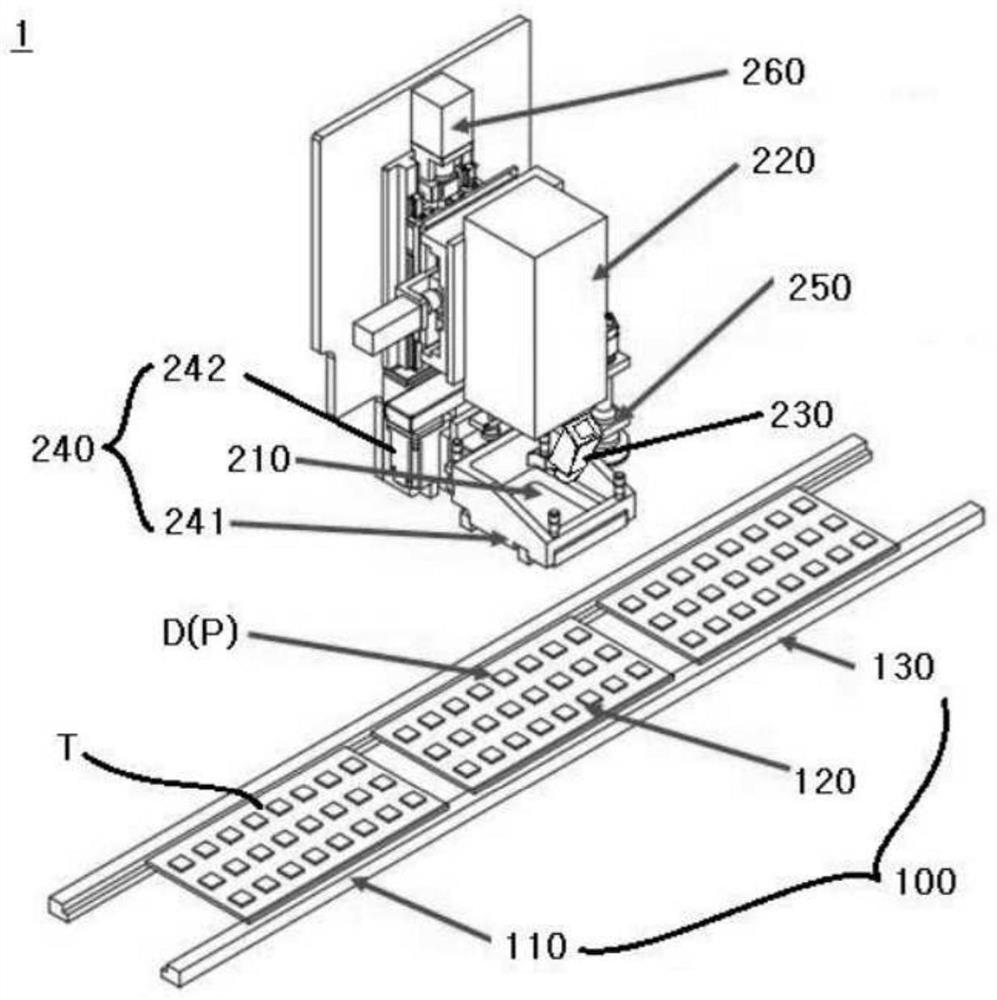

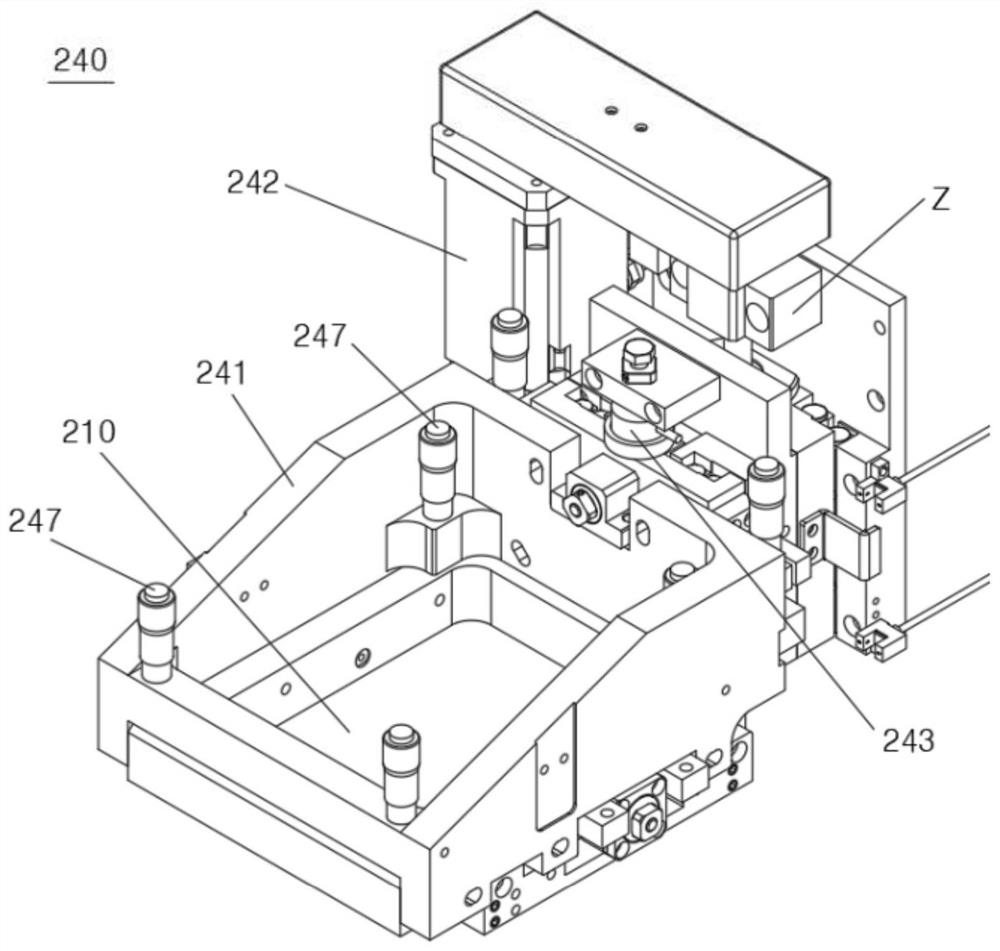

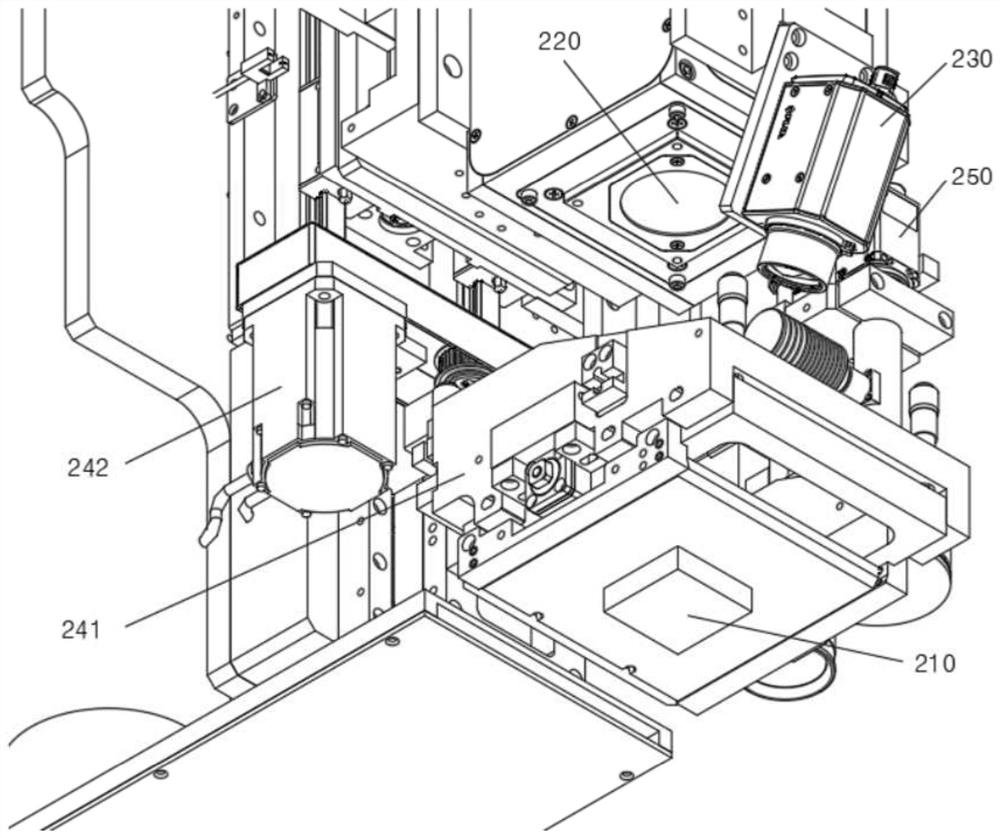

[0035] figure 1 A schematic configuration of a laser compression bonding apparatus according to the present invention is illustrated. figure 2 Illustrated in enlarged form figure 1 The lower part of the joint head in. image 3 Illustrated in enlarged form figure 1 in the bottom of the lower part of the engagement head.

[0036] As shown in the figure, the laser compression bonding apparatus 1 according to the present invention includes a conveyor unit 100 and a bonding head 200 . The conveyor unit 100 is configured to transfer the semiconductor chip (die) D and the substrate P from the pre-bonding area 110 to the unloading area 130 through the main bonding area 120 . The semiconductor chip D and the substrate P are received in the pre-bonding area 110 .

[0037]The bonding head 200 includes a bonding tool 210 , a laser beam generator 220...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com