Simple lamellar type self-heating element and preparation method and application thereof

A self-heating and simple technology, applied in the chemical industry, can solve the problems of thick, unsightly and large self-heating body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Preparation of simple sheet-type self-heating body

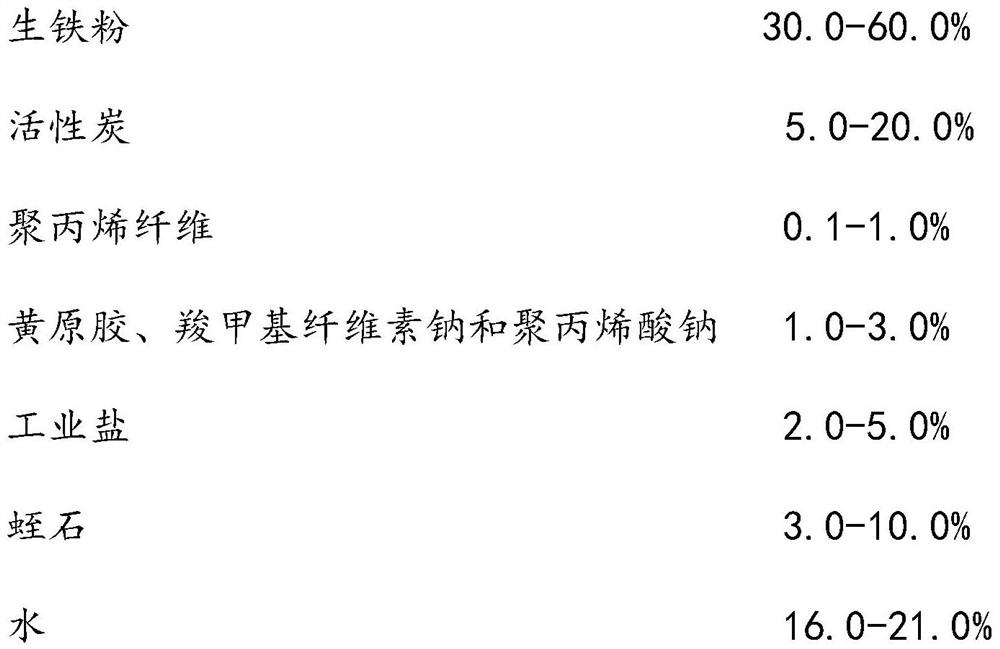

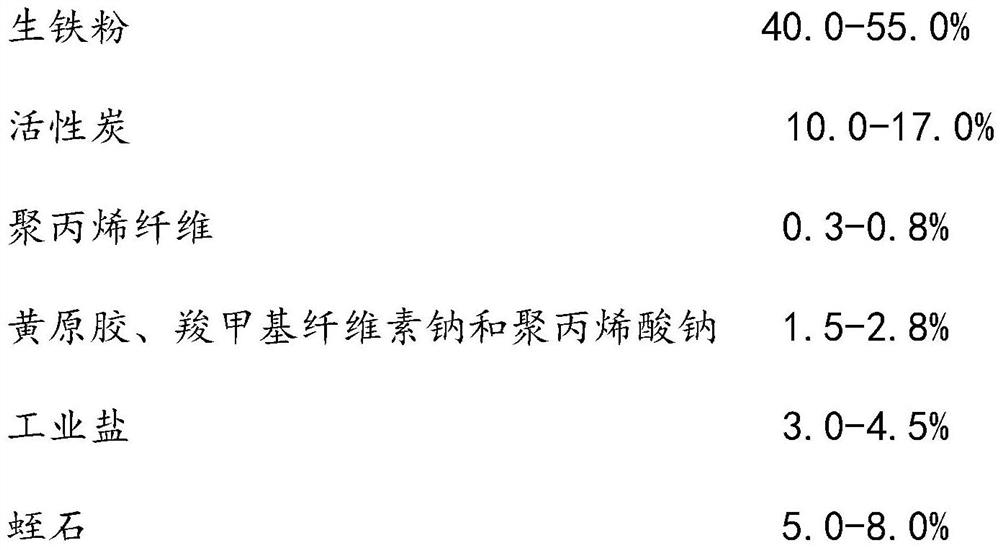

[0045] The materials are taken in the following parts by weight (see Table 1 for details). Take 50 parts of pig iron powder (powder particle size 150 mesh), 17 parts of activated carbon (powder particle size 150 mesh), 0.2 part of polypropylene fiber (length 4mm), 1 part of xanthan gum, sodium carboxymethylcellulose and polyacrylic acid Mixed powder of sodium (0.2 parts of xanthan gum powder, 0.4 parts of sodium carboxymethyl cellulose powder and 0.4 parts of sodium polyacrylate powder, the particle size of the three powders is 100 mesh), 9 parts of vermiculite powder (powder The particle size is 30 mesh) and mixed evenly under normal temperature and pressure to form a uniform powder.

[0046] Prepare 4 parts of industrial salt powder (powder particle size 40 mesh) and 18.8 parts of water to form a salt water mixture, and pour the above-mentioned uniform powder into the above-mentioned salt water mixture...

Embodiment 2

[0048] Example 2 Preparation of simple sheet-type self-heating body

[0049] The materials are taken in the following parts by weight (see Table 1 for details). Get 52 parts of pig iron powder (powder particle size 150 mesh), 14.6 parts of activated carbon (powder particle size 200 mesh), 0.5 part of polypropylene fiber powder (powder particle size 100 mesh), 2.5 parts of xanthan gum, sodium carboxymethyl cellulose and the mixed powder of sodium polyacrylate (wherein 0.8 part of xanthan gum powder, 1 part of sodium carboxymethyl cellulose powder and 0.7 part of sodium polyacrylate powder, the powder granularity of three kinds of powders is 100 orders), 7.4 parts of vermiculite powder ( The powder particle size is 40 mesh) and mixed uniformly under normal temperature and pressure to form a uniform powder.

[0050] Prepare 3.5 parts of industrial salt powder (40 mesh powder particle size) and 19.5 parts of water into a salt water mixture, and pour the above-mentioned uniform po...

Embodiment 3

[0052] Example 3 Preparation of simple sheet-type self-heating body

[0053] The materials are taken in the following parts by weight (see Table 1 for details). Get 55 parts of pig iron powder (powder particle size 150 mesh), 14.2 parts of activated carbon (powder particle size 200 mesh), 0.5 part of polypropylene fiber powder (powder particle size 100 mesh), 1.5 parts of xanthan gum, sodium carboxymethyl cellulose and the mixed powder of sodium polyacrylate (wherein 0.6 part of xanthan gum powder, 0.5 part of carboxymethyl cellulose sodium powder and 0.4 part of sodium polyacrylate powder, the powder granularity of three kinds of powders is 100 orders), 6.4 parts of vermiculite powder ( The powder particle size is 20 mesh) and mixed uniformly under normal temperature and pressure to form a uniform powder.

[0054] Prepare 3.5 parts of industrial salt powder (powder particle size 80 mesh) and 18.9 parts of water into a brine mixture, and pour the above-mentioned uniform powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com