A rock-like material satisfying the characteristics of water-induced strength degradation, its preparation method and application

A rock similarity and strength technology, applied in the field of geological engineering, can solve the problems of difficult to obtain the law of water-induced rock slope strength degradation, difficult to disintegrate, difficult to slide, etc., to improve bulk density and mechanical properties, simplify model making, simplify conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention provides a method for preparing a rock-like material satisfying the water-induced strength degradation characteristics according to the above technical solution, comprising the following steps:

[0041] Aggregate, cementitious material, additives and water are mixed, and cured after molding to obtain a rock-like material that satisfies the characteristics of water-induced strength deterioration.

[0042] In the present invention, the mass of the water is preferably 10-15% of the total mass of aggregate, cementitious material and additives, more preferably 11-12%.

[0043] In the present invention, the mixing method is preferably stirring and mixing. The present invention does not have any special restrictions on the speed and time of the stirring and mixing, as long as the preparation raw materials can be mixed uniformly; the mixing order is preferably to mix the aggregate and The cementitious materials are first mixed to obtain a dry material; the...

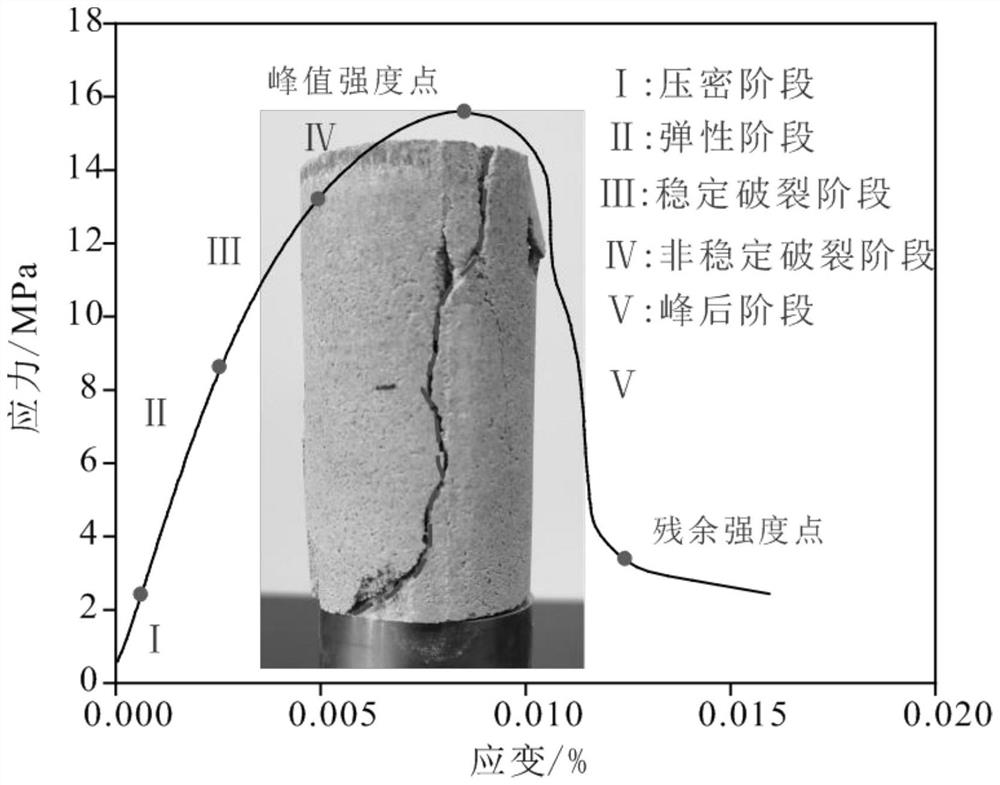

Embodiment 1

[0050] 222.50g quartz sand (grain size of 20-40 mesh coarse quartz sand: 40-70 mesh fine quartz sand mass ratio = 1:1), 89.00g barite powder (200 mesh size), 35.60g C425 type ordinary Portland cement, 53.40g of raw gypsum and 44.50g of bentonite (montmorillonite content>80wt%, particle size of 400 mesh) are mixed evenly, and then 55.00g of gypsum retarder aqueous solution (vegetable protein gypsum retarder) with a concentration of 0.01g / mL is added. Coagulant) mixed, the obtained wet material was filled in three layers into a steel mold washed with water and coated with lubricant, scratches were made at the layered place, and then placed on a hydraulic demolding instrument, at 20 ° C, Press molding under the condition of 10MPa for 8 minutes, then release the pressure to normal pressure, let it stand for 20 minutes at room temperature, and then release the mold, and then cure for 10 days at room temperature under dry and ventilated (humidity 50-60%) conditions to obtain the wate...

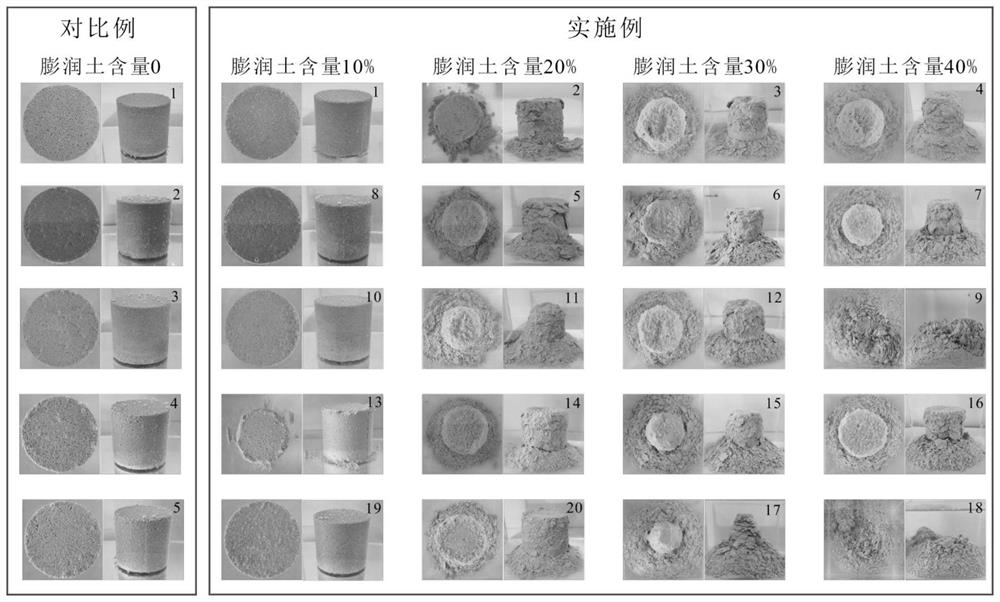

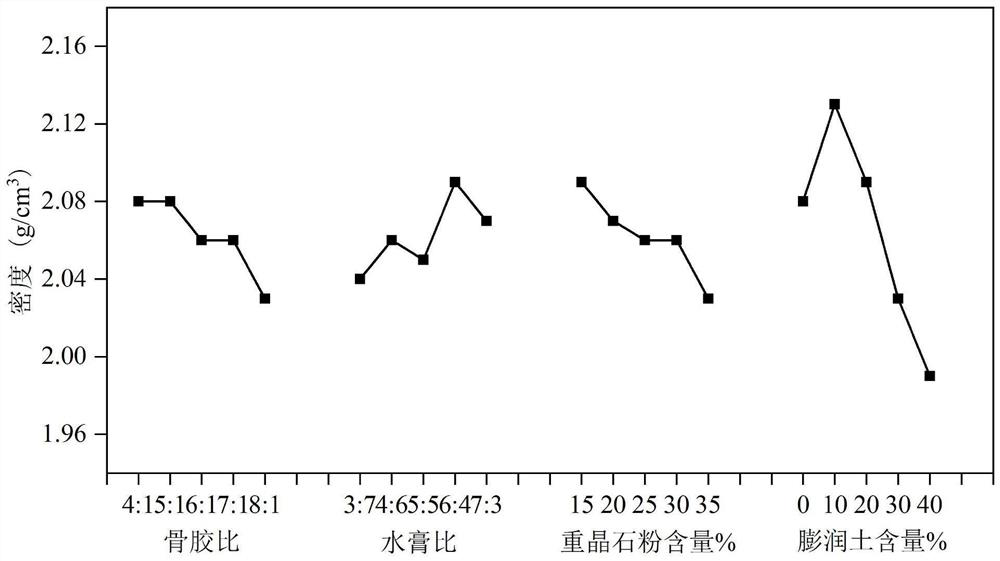

Embodiment 2~20

[0052] According to the method of Example 1, a rock-like material meeting the water-induced strength degradation characteristics was prepared, and the preparation raw materials of Examples 2 to 20 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com