Heat treatment process for improving high-temperature tensile plasticity of heat-resistant alloy

A heat-resistant alloy and tensile plasticity technology is applied in the field of heat treatment process for improving high-temperature tensile plasticity of heat-resistant alloys, which can solve the problems of reduced high-temperature yield strength and low strength, achieve good tensile plasticity, improve strength, and prevent cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

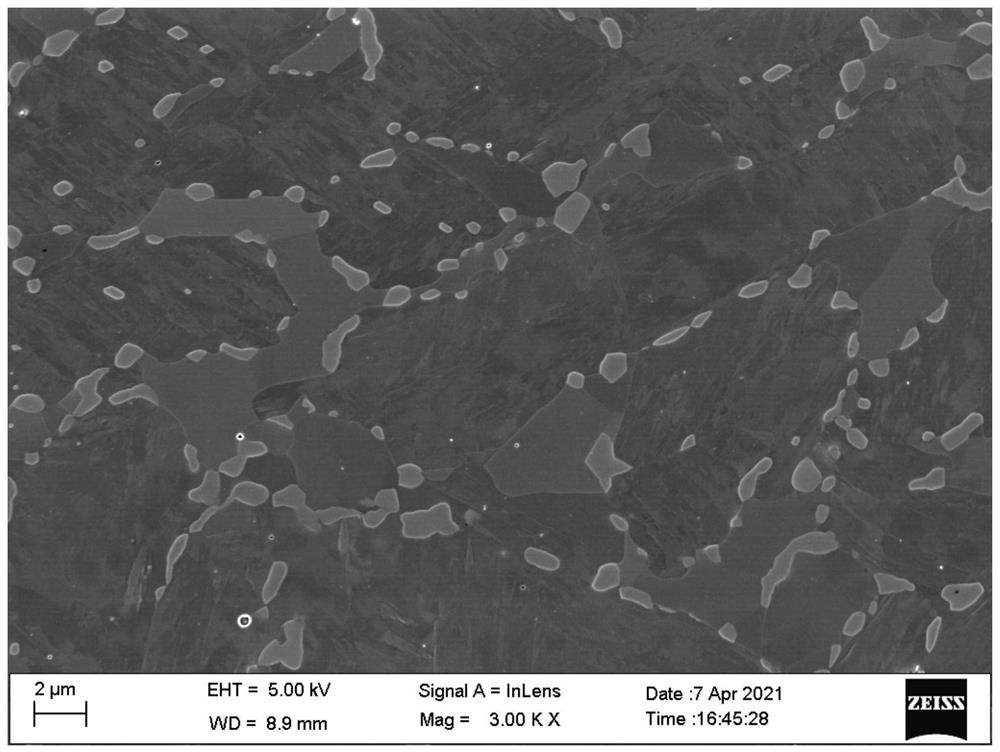

[0037] Step 1: Take the deformed heat-resistant alloy whose composition is heat-resistant alloy 1 in Table 1, the precipitation temperature of the second phase at the grain boundary of the heat-resistant alloy and the complete austenitization A c3 The temperatures were measured by experimental instruments and were 1102°C and 700.6°C, respectively. Now heat the heat-resistant alloy to 1000°C at a heating rate of 15°C per min, keep it warm for 30 minutes, and complete the solution treatment, and then water-cool to room temperature. Sample, the microstructure of the sample after solid solution treatment is as follows figure 1 shown. From figure 1 It can be seen that after the treatment in step 1, massive discontinuous precipitates precipitate at the austenite and martensite grain boundaries of the heat-resistant alloy, and their average size does not exceed 4 μm.

[0038] Step 2: Heat the sample after solid solution treatment to 750°C at a rate of 10°C per min, keep it warm fo...

Embodiment 2

[0040] Step 1: Take the deformed heat-resistant alloy whose composition is heat-resistant alloy 2 in Table 1, the precipitation temperature of the second phase at the grain boundary of the heat-resistant alloy and the complete austenitization A c3 The temperatures were measured by experimental instruments and were 1108°C and 706.4°C, respectively. Now heat the heat-resistant alloy to 990°C at a heating rate of 15°C / min, hold it for 30 minutes, and complete the solution treatment, then water-cool to room temperature, and the temperature of the cooling medium used for water cooling is not higher than 30°C. After the treatment in step 1, blocky phases are discontinuously precipitated at the grain boundary between austenite and martensite, with an average size of no more than 4 μm.

[0041]Step 2: Heat the sample after solid solution treatment to 750°C at a heating rate of 10°C / min, hold it for 12 hours, complete the aging treatment, and then water-cool, the temperature of the coo...

Embodiment 3

[0051] Step 1: The deformed heat-resistant alloy includes the following components by weight percentage, C: 0.05%, Cr: 11.5%, Ni: 1.6%, Mn: 10%, Si: 0.3%, B: 0.007%, Mo: 1.5 %, W: 4%, Cu: 1.2%, Al: 1%, and the balance is Fe.

[0052] It is measured that the precipitation temperature of the second phase at the grain boundary of the alloy is 1106°C, and its complete austenitization A c3 The temperature was 705°C. Now heat the heat-resistant alloy to 998°C at a heating rate of 15°C / min, hold it for 30 minutes, and complete the solution treatment, then water-cool to room temperature, and the temperature of the cooling medium used for water cooling is not higher than 30°C. After solution treatment, massive phases are discontinuously precipitated at the grain boundary between austenite and martensite, and the average size does not exceed 4 μm.

[0053] Step 2: Heat the sample after solid solution treatment to 760°C at a heating rate of 10°C / min, keep it warm for 12 hours, complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com