Expansion-pipe-type automatic gap-adjusting piston mechanism

A piston mechanism, automatic adjustment technology, applied in the direction of brake actuator, gear transmission mechanism, mechanical equipment, etc., can solve the problems of heavy weight and large structure space, and achieve the effect of light weight, small structure space, and reducing friction and damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

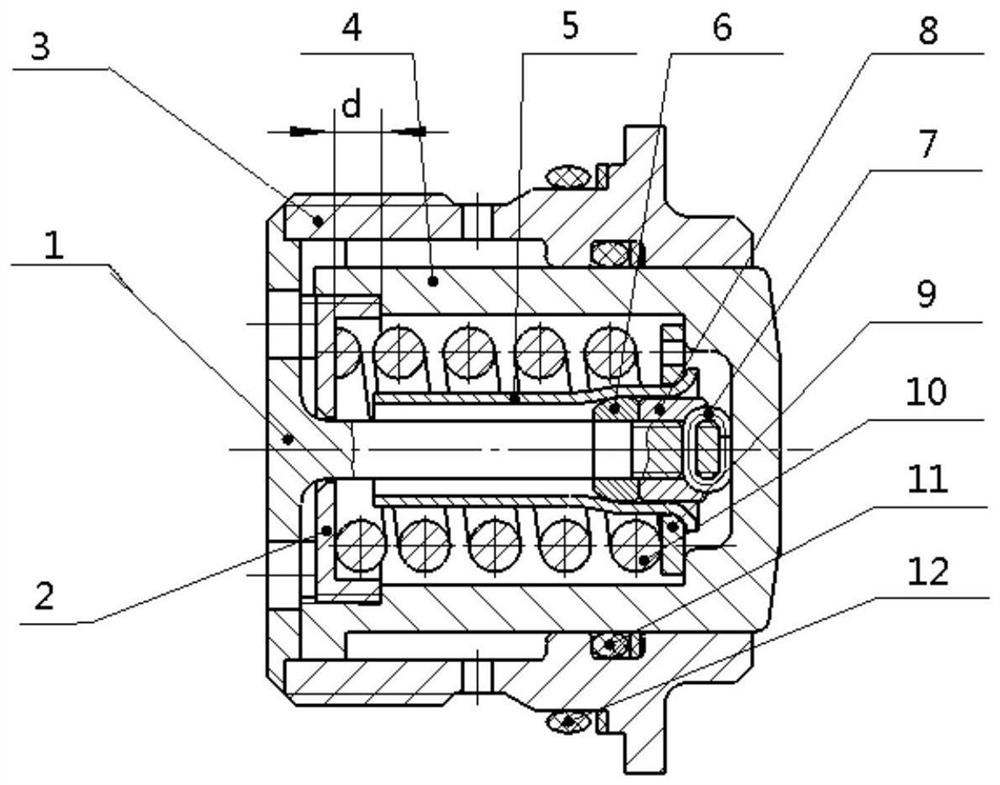

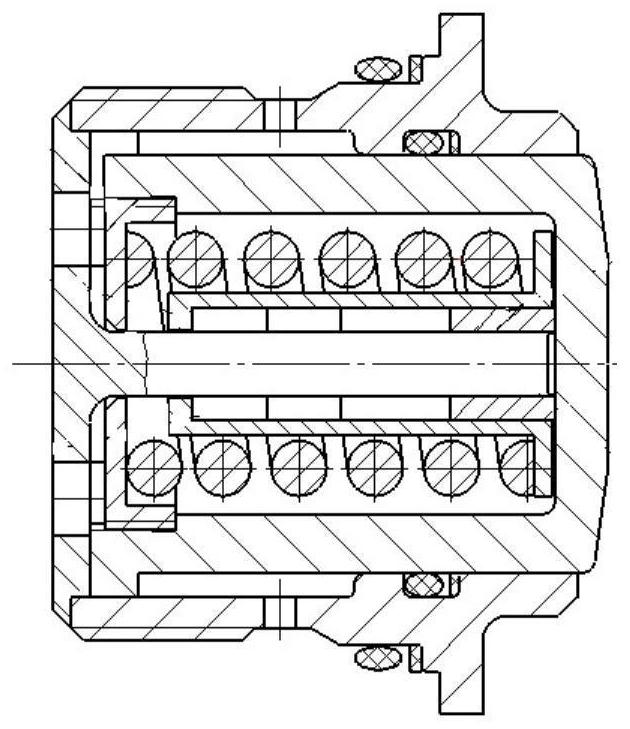

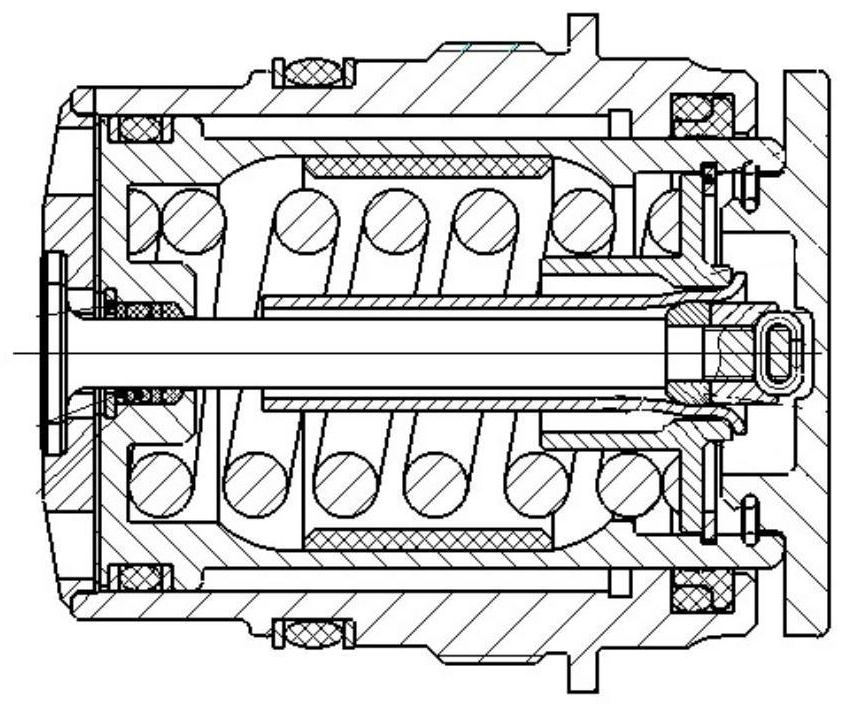

[0034] This embodiment is an automatic gap adjustment hydraulic piston structure, including a pull rod 1, a screw cap 2, a bushing 3, a piston 4, an expansion tube 5, a ball head 6, a stainless steel wire 7, a spring seat 9, a spring 10, and a sealing ring 11 and protective ring 12. in:

[0035] A ball head 6 is set on the end of the working section of the tie rod, and a nut 8 is set on the outside of the ball head, and is locked by a stainless steel wire 7; the nut is a hexagonal slotted nut. The expansion tube 5 is sleeved on the ball head, and the flared end of the expansion tube is sleeved on the outer surface of the ball head and the nut. The spring 10 is sleeved on the outer circumferential surface of the expansion tube, and the inner end of the spring is fitted to the end face of the screw cap 2 sleeved at the root of the working section of the pull rod, so that the outer end of the spring is sleeved on the The inner end surface of the spring seat 9 on the outer circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com