High-efficiency semiconductor laser

A laser and semiconductor technology, applied in the structure of optical waveguide semiconductors, etc., can solve the problems of high power density, reduced electro-optical conversion efficiency, uneven distribution of optical power density, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

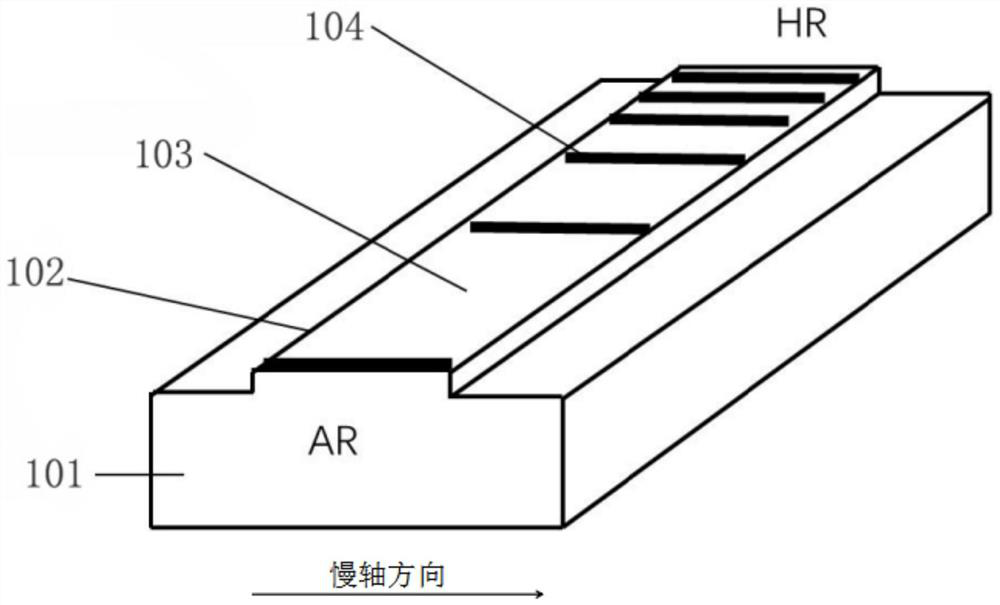

[0027] Aiming at the problem of the spatial hole burning effect in the current bar-type semiconductor laser, a high-efficiency semiconductor laser is specifically provided in this embodiment, such as figure 1 As shown, it mainly includes a substrate 101 .

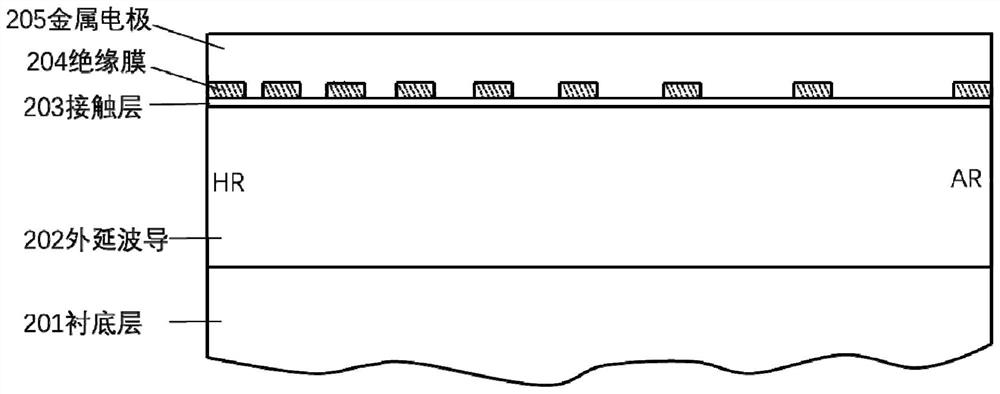

[0028] Also includes: a strip waveguide 102 arranged on the substrate 101, the strip waveguide 102 is arranged on the substrate 101, the width of the strip waveguide 102 is 100 microns, the etching depth of the strip waveguide 102 is 500nm, the strip waveguide 102 has a length of 4 mm. Such as figure 2 As shown, the strip waveguide 102 includes an epitaxial waveguide 202 disposed on the upper side of the substrate 101 layer, the upper side of the epitaxial waveguide 202 is provided with a contact layer 203, and the upper side of the contact layer 203 is arranged with the insulating regions at intervals. 104 , and the upper side of the contact layer 203 is covered with a metal electrode 205 . Wherein, each insulating reg...

Embodiment 2

[0034] Aiming at the problem of the spatial hole-burning effect in the current bar-type semiconductor laser, another high-efficiency semiconductor laser is specifically provided in this embodiment, and its structure is shown in figure 1 , figure 2 shown. During implementation of this embodiment, a strip waveguide 102 is provided on the substrate 101. The width of the strip waveguide 102 is 120 microns, the etching depth of the strip waveguide 102 is 550 nm, and the length of the strip waveguide 102 is 5 mm. Such as figure 2 As shown, the strip waveguide 102 includes an epitaxial waveguide 202 disposed on the upper side of the substrate 101 layer, the upper side of the epitaxial waveguide 202 is provided with a contact layer 203, and the upper side of the contact layer 203 is arranged with the insulating regions at intervals. 104 , and the upper side of the contact layer 203 is covered with a metal electrode 205 . Wherein, each insulating region 104 is an insulating film 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com