Mass concrete block, pouring construction method and dam obtained through pouring

A large-volume concrete and concrete technology, applied in construction, artificial islands, water conservancy projects, etc., can solve problems that affect the safety and normal use of structures, and large-volume concrete temperature cracks, so as to improve the flexural strength and anti-crack performance, reduce The effect of cracking and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

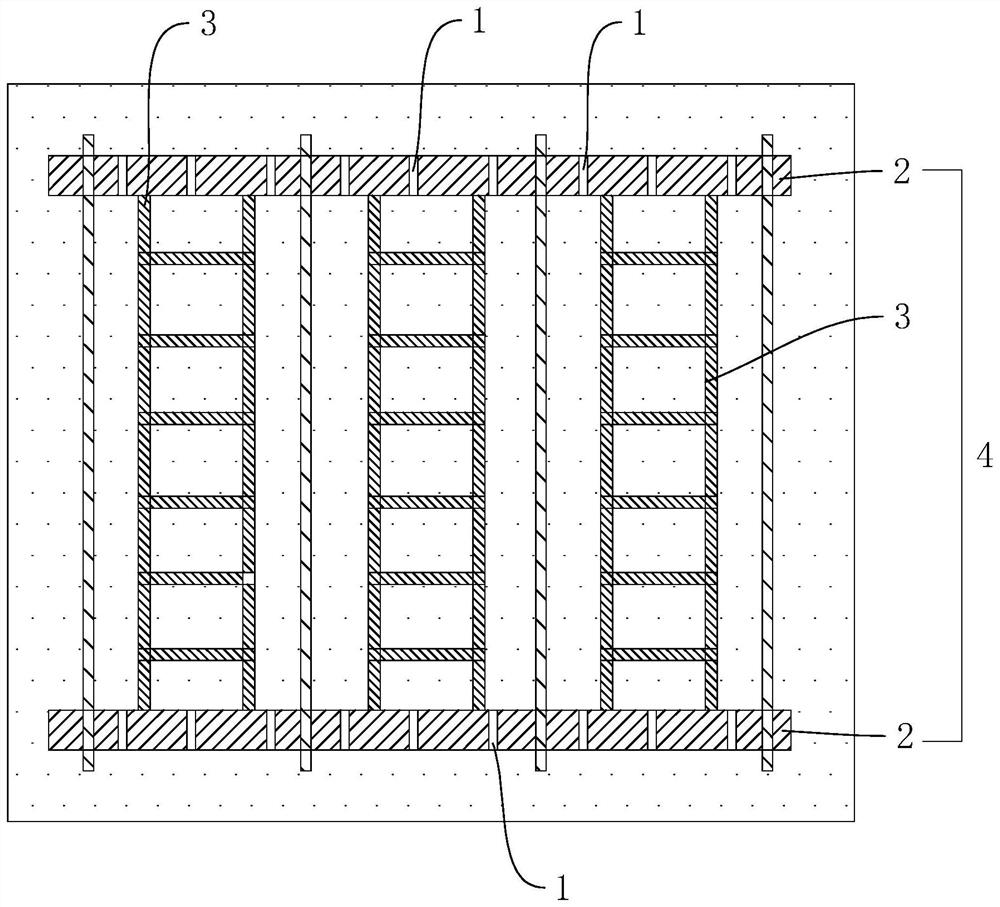

[0052] A mass concrete block, ref. figure 1 The above-mentioned large-volume concrete block is obtained by tamping holes on the surface of the uncured large-volume concrete block after pouring the concrete slurry, and it is required to have 9 holes 1 evenly distributed on the surface of the large-volume concrete block per square meter, and each hole 1 hole The diameter is controlled at about 1cm. The above-mentioned large-volume concrete block after pouring and molding contains two porous stainless steel plates 2 arranged at intervals, and the two adjacent porous stainless steel plates 2 are fixed by plastic binding. There are a plurality of reinforcement cages 3 between two adjacent porous stainless steel plates 2, and the reinforcement cages 3 and the porous stainless steel plates 2 are fixed by binding steel wires.

[0053] The concrete slurry in this embodiment includes the components and dosages shown in Table 1. Among them, the fine aggregate is freshwater sand (namely...

Embodiment 2

[0061] A large-volume concrete block, which differs from Example 1 in that: the above-mentioned large-volume concrete block after pouring and molding contains three porous stainless steel plates 2 arranged at intervals, and plastic is used between two adjacent porous stainless steel plates 2 Binding and fixing, the above hole 1 communicates with the opening of the porous stainless steel plate 2. There are a plurality of reinforcement cages 3 between two adjacent porous stainless steel plates 2, and the reinforcement cages 3 and the porous stainless steel plates 2 are bound and fixed by plastic cable ties. Wherein, there are three holes 1 on the surface of the large-volume concrete block per square meter, and the diameter of each hole 1 is controlled at about 3 cm.

[0062] The components and dosage of the concrete slurry are different, and the components and dosage of the concrete slurry in this embodiment are shown in Table 1. Among them, the fine aggregate is freshwater san...

Embodiment 4-7

[0079] A large-volume concrete block, the difference from Example 1 is that the components and dosage of the concrete slurry are different, and the components and dosage of the concrete slurry in this example are shown in Table 1.

[0080] Table 1 Components and consumption (kg) of concrete slurry embodiment 1-7

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness modulus | aaaaa | aaaaa |

| Fineness modulus | aaaaa | aaaaa |

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com