Auxiliary agent for improving flame retardant property of polymer coiled material

A flame retardant and polymer technology, which is applied in the field of additives to improve the flame retardant performance of polymer membranes, can solve the problems that the flame retardant performance of PVC waterproof membranes cannot be improved, and the best flame retardant effect cannot be achieved. Achieve the effect of improved dispersion uniformity, excellent flame retardant effect and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

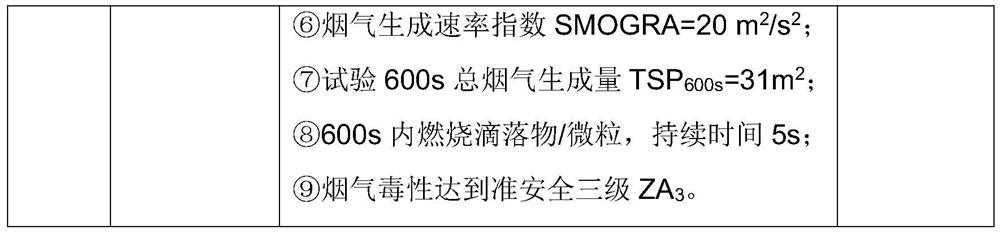

Examples

Embodiment example 1

[0062] A composite flame retardant, the composition is as follows:

[0063] Decabromodiphenylethane 25%

[0065] Molybdenum trioxide 5%

[0067] A polyvinyl chloride macromolecule waterproof membrane, the formula is as follows:

[0068]

[0069] Preparation of polyvinyl chloride polymer waterproof membrane:

[0070] S1. Mix polyvinyl chloride resin, light calcium, titanium dioxide, carbon black and composite flame retardant according to the weight ratio, then add plasticizer DOP, and mix evenly to obtain a mixed material;

[0071] S2. Feed the above mixture into a twin-screw extruder, set the temperature of the extruder to 200-250°C, set the speed to 300-400 rpm, and extrude to make tablets with a thickness of 1.2mm .

[0072] Curing conditions: 23°C±2°C, humidity 60%±15%, observe after 24 hours of curing, the surface of the sheet is smooth, the edges are neat, and there are no cracks, voids, bonds, bubbles...

Embodiment example 2

[0077] A composite flame retardant, the composition is as follows:

[0078] Decabromodiphenylethane 15%

[0080] Molybdenum trioxide 5%

[0082] A polyvinyl chloride macromolecule waterproof membrane, the formula is as follows:

[0083]

[0084] Preparation of polyvinyl chloride polymer waterproof membrane:

[0085] S1. Mix polyvinyl chloride resin, light calcium, titanium dioxide, carbon black and composite flame retardant according to the weight ratio, then add plasticizer DOP, and mix evenly to obtain a mixed material;

[0086] S2. Feed the above mixture into a twin-screw extruder, set the temperature of the extruder to 200-250°C, set the speed to 300-400 rpm, and extrude to make tablets with a thickness of 1.2mm .

[0087] Curing conditions: 23°C±2°C, humidity 60%±15%, observe after 24 hours of curing, the surface of the sheet is smooth, the edges are neat, and there are no cracks, voids, bonds, bubble...

Embodiment example 3

[0092] A composite flame retardant, the composition is as follows:

[0093] Decabromodiphenylethane 25%

[0095] Molybdenum trioxide 5%

[0096] Calcium Carbonate 60%.

[0097] A polyvinyl chloride macromolecule waterproof membrane, the formula is as follows:

[0098]

[0099] Preparation of polyvinyl chloride polymer waterproof membrane:

[0100] S1. Mix polyvinyl chloride resin, light calcium, titanium dioxide, carbon black and composite flame retardant according to the weight ratio, then add plasticizer DOP, and mix evenly to obtain a mixed material;

[0101] S2. Feed the above mixture into a twin-screw extruder, set the temperature of the extruder to 200-250°C, set the speed to 300-400 rpm, and extrude to make tablets with a thickness of 1.2mm .

[0102] Curing conditions: 23°C±2°C, humidity 60%±15%, observe after 24 hours of curing, the surface of the sheet is smooth, the edges are neat, and there are no cracks, voids, bonds, bubble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com