High-adhesion quick-drying type PVC white inkjet film and preparation method thereof

A high-adhesion, quick-drying technology, applied in the field of inkjet materials, can solve the problems affecting the overall aesthetics of the wall, poor durability and adaptability, and complicated drying procedures, so as to enhance the adsorption capacity, penetration capacity and printing effect. Realistic, weather-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

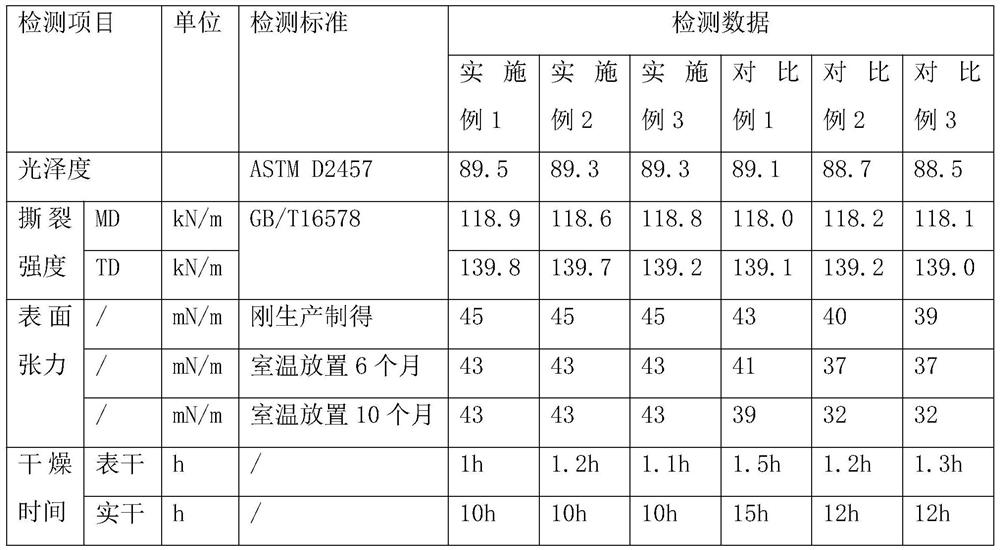

Examples

Embodiment 1

[0029] A high-adhesion quick-drying PVC white inkjet film, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 45 parts of plasticizer, 4 parts of stabilizer, 2 parts of epoxy soybean oil, 13 parts of filler, coloring material 1 part, 1 part of processing aid and 0.8 part of dispersing aid;

[0030] Wherein, the PVC resin is formed by mixing PVC resin A and PVC resin B with a mass ratio of 1:3, and the K value of the PVC resin A is 70, and the K value of the PVC resin B is 65. The filler is a mixture of calcium carbonate and lithium oxide, and the mass ratio of calcium carbonate and lithium oxide is 1:0.1.

[0031] The preparation method of the above-mentioned high-adhesion fast-drying type PVC white spray-painted film is as follows:

[0032] (1) Mix each component according to the above mass ratio, stir evenly in a high-speed mixer, and then banbury and plasticize in an internal mixer for 8 minutes until it becomes a gel-like colloid;

[0033]...

Embodiment 2

[0037] A high-adhesion quick-drying PVC white inkjet film, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 35 parts of plasticizer, 3 parts of stabilizer, 1 part of epoxy soybean oil, 12 parts of filler, and coloring material 0.5 parts, 0.5 parts of processing aids and 0.5 parts of dispersing aids;

[0038] Wherein, the PVC resin is formed by mixing PVC resin A and PVC resin B with a mass ratio of 1:4, and the K value of the PVC resin A is 70, and the K value of the PVC resin B is 65. The filler is a mixture of calcium carbonate and lithium oxide, and the mass ratio of calcium carbonate and lithium oxide is 1:0.05.

[0039] The preparation method of the above-mentioned high-adhesion fast-drying type PVC white spray-painted film is as follows:

[0040] (1) Mix each component according to the above mass ratio, stir evenly in a high-speed mixer, and then banbury and plasticize in an internal mixer for 5 minutes until it becomes a gel-like collo...

Embodiment 3

[0045] A high-adhesion quick-drying PVC white inkjet film, comprising the following raw materials in parts by weight: 100 parts of PVC resin, 50 parts of plasticizer, 5 parts of stabilizer, 3 parts of epoxy soybean oil, 15 parts of filler, and coloring material 2 parts, 2 parts of processing aid and 1 part of dispersing aid;

[0046] Wherein, the PVC resin is formed by mixing PVC resin A and PVC resin B with a mass ratio of 3:7, and the K value of the PVC resin A is 70, and the K value of the PVC resin B is 65. The filler is a mixture of calcium carbonate and lithium oxide, and the mass ratio of calcium carbonate and lithium oxide is 1:0.2.

[0047] The preparation method of the above-mentioned high-adhesion fast-drying type PVC white spray-painted film is as follows:

[0048] (1) Mix each component according to the above mass ratio, stir evenly in a high-speed mixer, and then banbury and plasticize in an internal mixer for 10 minutes until it becomes a gel-like colloid;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com