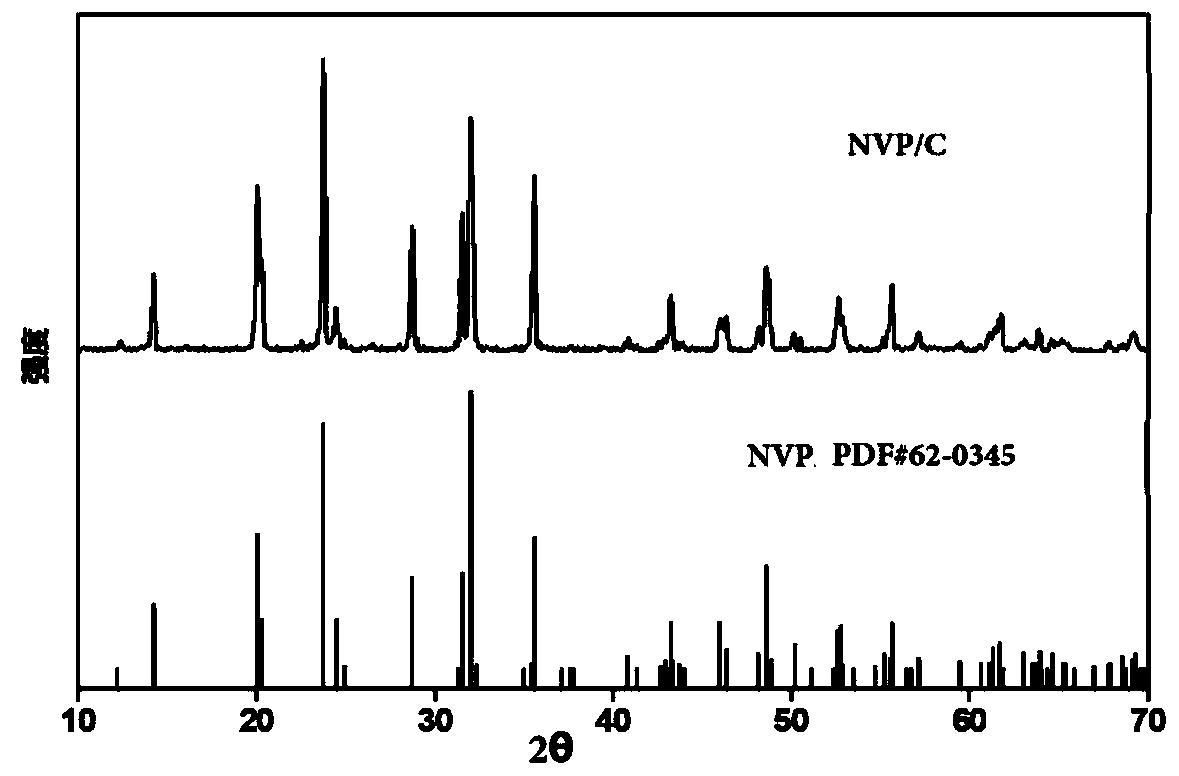

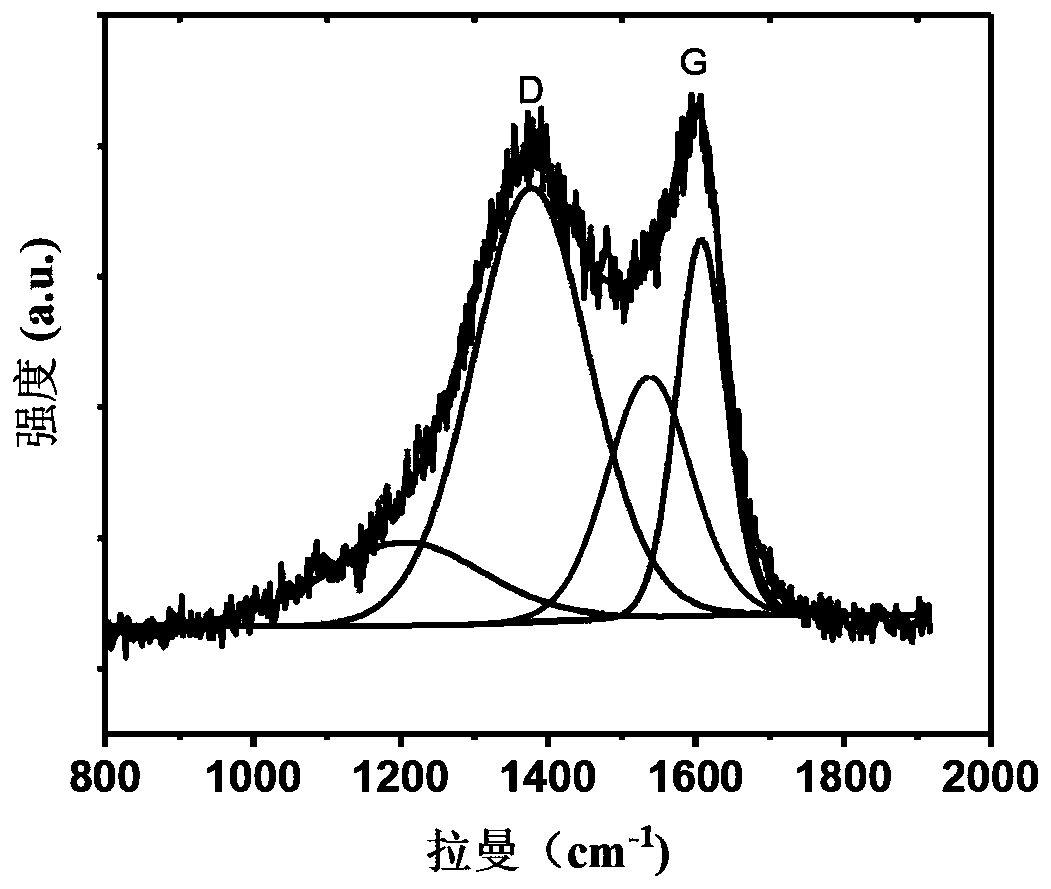

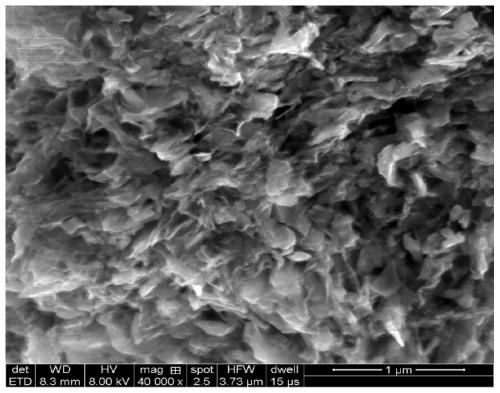

A nitrogen-hydrogen in-situ double-doped soft carbon/sodium vanadium phosphate composite material and its preparation method and application

A technology of sodium vanadium phosphate and composite materials, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of organic solvent DMF, which is not environmentally friendly, poor in electrical conductivity and electrochemical performance, and high cost of synthetic materials, and achieves improved strength and The effect of structural stability, good compatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of nitrogen-hydrogen in-situ double-doped soft carbon / sodium vanadium phosphate composite material, the steps are as follows:

[0043] Soak 6g of soybeans in 40ml of 15% ethanol aqueous solution for 5h, grind it into a slurry with 60mL of 15wt% ethanol aqueous solution and pass through a 120 mesh sieve, then heat the soybean milk at 100°C for 0.5h to obtain solution A; Add 4.6g of ammonium metavanadate and 4.68g of sodium dihydrogen phosphate dihydrate into solution A, stir in a water bath at 80°C for 0.5h to dissolve and react, then adjust pH=5 with acetic acid to condense the system to obtain condensate and liquid Mixture B; put the mixture B into the reaction kettle and keep it under water heat for 24 hours at 100°C, and dry the obtained solidified body at 80°C for 6 hours; grind the dried solidified body to less than 100um under nitrogen, and pass it from the chamber at 5°C / min The temperature was raised to 350°C for 4 hours, and then heated to ...

Embodiment 2

[0052] A preparation method of nitrogen-hydrogen in-situ double-doped soft carbon / sodium vanadium phosphate composite material, the steps are as follows:

[0053] Soak 7g soybeans in 50ml mass concentration of 10% ethanol aqueous solution for 4h, grind it into a slurry with 60mL 10wt% ethanol aqueous solution and pass through an 80 mesh sieve, then heat the soybean milk at 80°C for 0.5h to obtain solution A; Add 4.6 g of ammonium metavanadate and 4.68 g of sodium dihydrogen phosphate dihydrate to solution A, stir in a water bath at 100°C for 0.5 h to dissolve and react, then adjust the pH to 6 with acetic acid to coagulate the system to obtain condensate and liquid Mixture B; put the mixture B into the reaction kettle and keep it under water heat for 22h at 120°C, and dry the solidified body at 100°C for 5h; grind the dry solidified body to less than 100um, and put it under nitrogen at 4°C / min from the chamber The temperature was raised to 300°C for 6 hours, and then heated to...

Embodiment 3

[0056] A preparation method of nitrogen-hydrogen in-situ double-doped soft carbon / sodium vanadium phosphate composite material, the steps are as follows:

[0057] Soak 5g of black beans in 30ml of 20% ethanol aqueous solution for 8h, grind it into a slurry with 60mL of 20wt% ethanol aqueous solution and pass through a 120 mesh sieve, then heat the soybean milk at 100°C for 0.5h to obtain solution A; Add 4.6g of ammonium metavanadate and 4.68g of sodium dihydrogen phosphate dihydrate to solution A, stir in a water bath at 100°C for 0.5h to dissolve and react, then use acetic acid to adjust pH=4 to coagulate the system to obtain condensate and liquid The mixture B; put the mixture B into the reaction kettle and keep it at 80°C for 26h, and dry the obtained solidified body at 60°C for 8h; grind the dried solidified body to less than 100um and put it under nitrogen at 7°C / min from the chamber The temperature was raised to 400°C for 3 hours, and then heated to 900°C at 5°C / min for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com