Explosion-proof method and device for self-propagating production of kilogram-level γ-tialnb alloy in one-step furnace

A kilogram-level, self-propagating technology, which is applied in the field of titanium-aluminum-niobium ternary alloy materials, can solve problems such as the difficulty in realizing kilogram-level production and the inability to realize continuous automatic production, so as to avoid uncontrollable self-propagating reactions induced by reaction heat , Improve safety, reduce the effect of reaction heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

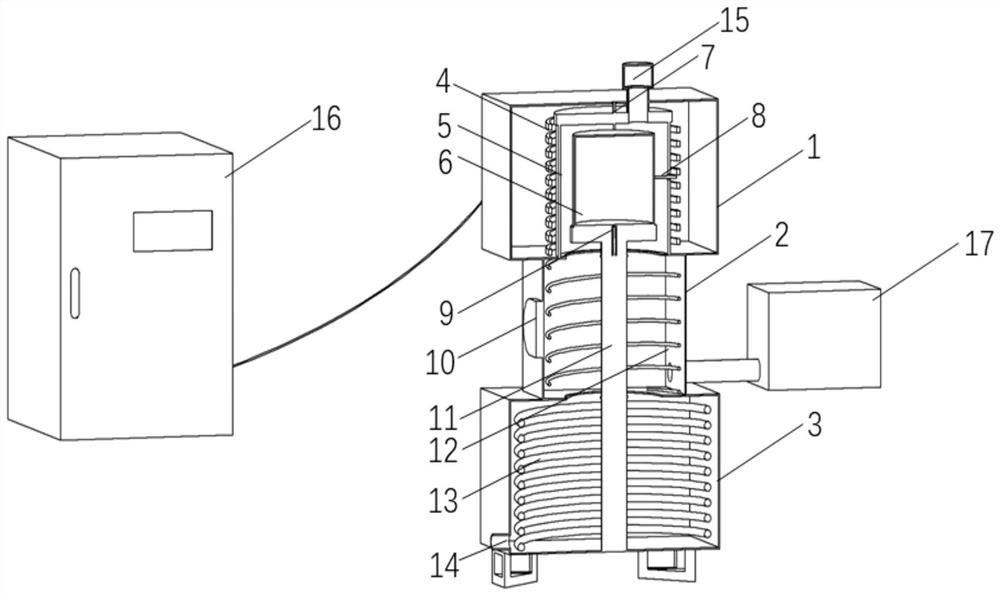

[0046] An explosion-proof device for self-propagating production of kilogram-level γ-TiAlNb alloy in a one-step furnace, the schematic diagram of which is shown in figure 1 ; It is a non-ignition reaction furnace, including a heating zone furnace body 1, a slow cooling zone furnace body 2 and a deep cooling zone furnace body 3; wherein, a heating zone furnace body 1, a slow cooling zone furnace body 2 and a deep cooling zone furnace body 3 Connected sequentially, the furnace body 1 in the heating zone is an induction heating furnace body, which forms a heating zone, the furnace body 2 in the slow cooling zone forms a slow cooling zone, and the furnace body 3 in the deep cooling zone forms a deep cooling zone, the heating zone, the slow cooling zone and the deep cooling zone The areas are sequentially connected;

[0047] The inner ring of the furnace body 1 in the heating zone is provided with a graphite heating element 5, and the outer circumference of the graphite heating ele...

Embodiment 2

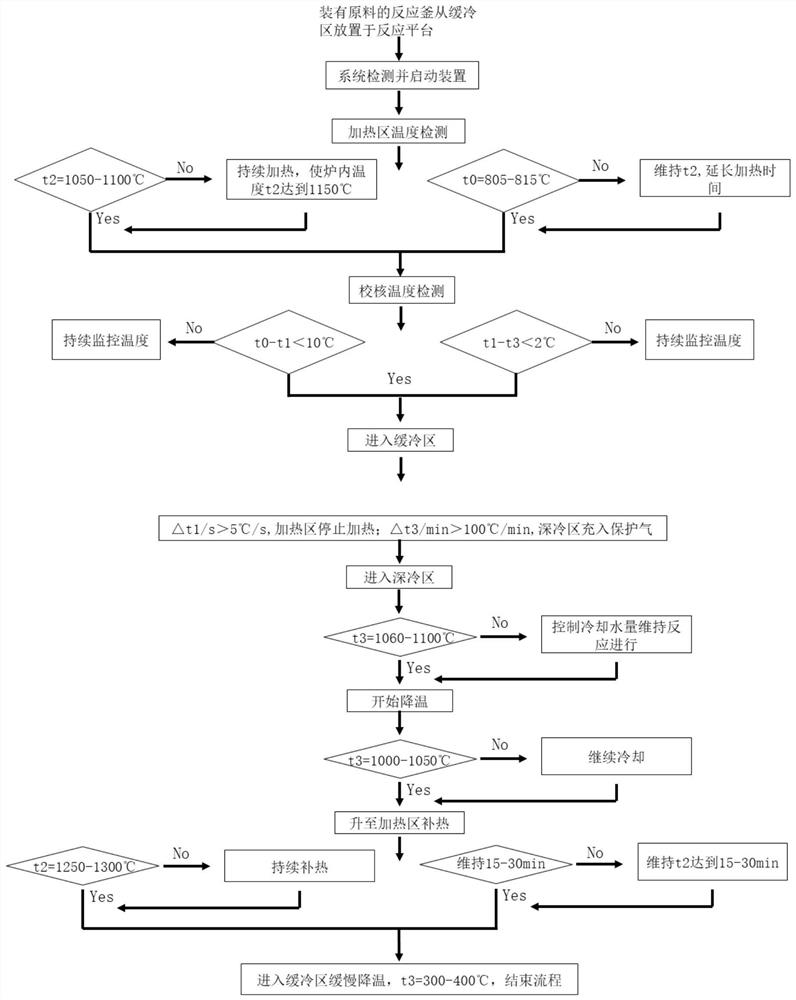

[0063] In this embodiment, an explosion-proof method for producing kilogram-level γ-TiAlNb alloy by self-propagation in a one-step furnace, the device used is the same as that in Embodiment 1, and the specific steps in the implementation process of this embodiment are:

[0064] Step 1, according to the preparation level of the γ-TiAlNb ternary alloy above the kilogram level, prepare the raw materials, in the raw materials according to the mass ratio Ti:Al:CaO:NaClO 4 :ZrO 2 :Nb=48:65:13:35:19:2 Mixed, the total mass is 10kg, after uniform mixing, sent to a drying box for drying treatment, to obtain a raw material mixture.

[0065] Step 2, place the pretreated raw material mixture in a ceramic crucible, and place the crucible in a reaction kettle, start vacuuming, and when the vacuum degree reaches 10 -3 Heating starts at Pa.

[0066] Among them, the three thermocouples distributed in the heating area can be used to detect the actual temperature t1 on the upper surface of the...

Embodiment 3

[0070] This embodiment is an explosion-proof method for self-propagating production of kilogram-level γ-TiAlNb alloy in a one-step furnace. The device used is the same as that of Embodiment 1. The specific steps in the implementation process of this embodiment are:

[0071] Step 1, according to the preparation level of the γ-TiAlNb alloy above the kilogram level, prepare the raw materials, in the raw materials according to the mass ratio Ti:Al:CaO:NaClO 4 :ZrO 2 :Nb=47:64:14:37:22:2 Mixed, the total mass is 10kg, after uniform mixing, sent to the drying box for drying treatment, to obtain the raw material mixture.

[0072] Step 2, the pretreated raw material mixture is placed in a ceramic crucible, and the crucible is placed in a reaction kettle, and a vacuum is started, and when the vacuum degree reaches 10 -3 Heating starts at Pa.

[0073] Among them, the three thermocouples distributed in the heating area can be used to detect the actual temperature t1 on the upper surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com