Vanadium-containing hot-based galvanized sheet and preparation method thereof

A technology of galvanized sheet and substrate, applied in the field of metallurgy, can solve the problems of poor steel plasticity, low elongation, poor welding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

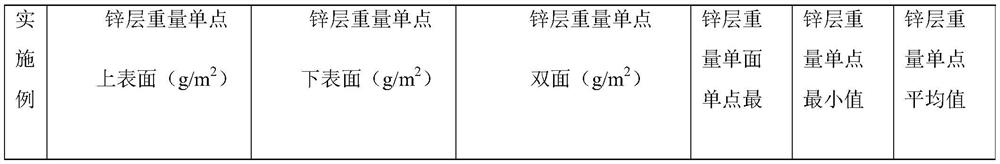

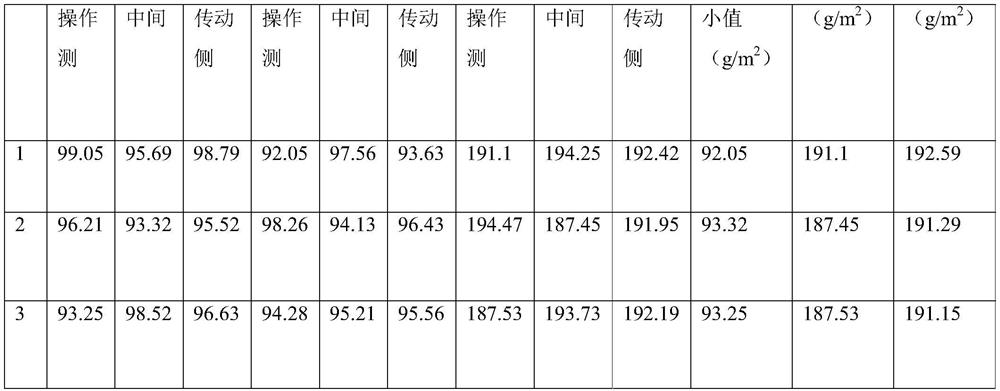

Examples

Embodiment 1

[0029] A vanadium-containing heat-based galvanized sheet, the substrate of which includes the following components in mass percentage: C: 0.175%, Si: 0.12%, Mn: 0.26%, P: 0.011%, V: 0.051%, S: 0.02%, Cu : 0.014%, Ni: 0.023%, Cr: 0.027%, the balance is Fe and unavoidable impurities.

[0030] The preparation method of above-mentioned vanadium-containing heat-based galvanized sheet is:

[0031] The molten steel conforming to the composition of the above vanadium-containing hot-base galvanized sheet substrate is cast into continuous casting slabs, and the finished coils are rolled off the production line in the hot rolling production line, and then undergo three-stage pickling, five-stage rinsing, annealing, galvanizing, gas Knife purging, post-plating cooling, skin pass and coiling processes to obtain vanadium-containing heat-based galvanized sheet;

[0032] Among them, the three-stage pickling requirements: uncoiler tension 45KN, entrance looper tension 48KN, scale breaking mac...

Embodiment 2

[0044] A vanadium-containing heat-based galvanized sheet, the substrate of which includes the following components in mass percentage: C: 0.13%, Si: 0.12%, Mn: 0.25%, P: 0.01%, V: 0.042%, S: 0.005%, Cu : 0.01%, Ni: 0.018%, Cr: 0.02%, the balance is Fe and unavoidable impurities.

[0045] The preparation method of above-mentioned vanadium-containing heat-based galvanized sheet is:

[0046] The molten steel conforming to the composition of the above vanadium-containing hot-base galvanized sheet substrate is cast into continuous casting slabs, and the finished coils are rolled off the production line in the hot rolling production line, and then undergo three-stage pickling, five-stage rinsing, annealing, galvanizing, gas Knife purging, post-plating cooling, skin pass and coiling processes to obtain vanadium-containing heat-based galvanized sheet;

[0047] Among them, the three-stage pickling requirements: uncoiler tension 40KN, entrance looper tension 55KN, scale breaker tension...

Embodiment 3

[0059] A vanadium-containing heat-based galvanized sheet, the substrate of which includes the following components in mass percentage: C: 0.14%, Si: 0.13%, Mn: 0.257%, P: 0.008%, V: 0.045%, S: 0.005%, Cu : 0.01%, Ni: 0.012%, Cr: 0.015%, the balance is Fe and unavoidable impurities.

[0060] The preparation method of above-mentioned vanadium-containing heat-based galvanized sheet is:

[0061] The molten steel conforming to the composition of the above vanadium-containing hot-base galvanized sheet substrate is cast into continuous casting slabs, and the finished coils are rolled off the production line in the hot rolling production line, and then undergo three-stage pickling, five-stage rinsing, annealing, galvanizing, gas Knife purging, post-plating cooling, skin pass and coiling processes to obtain vanadium-containing heat-based galvanized sheet;

[0062] Among them, the three-stage pickling requirements: uncoiler tension 48KN, entrance looper tension 52KN, scale breaking mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com