Composite pumped storage system and operation method thereof

A pumped storage and composite technology, applied in the field of physical energy storage, can solve problems such as ecological environment damage, damage to civil engineering, system efficiency reduction, etc., achieve efficient and stable operation, high-efficiency variable working conditions, and avoid environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific example the present invention is described in further detail:

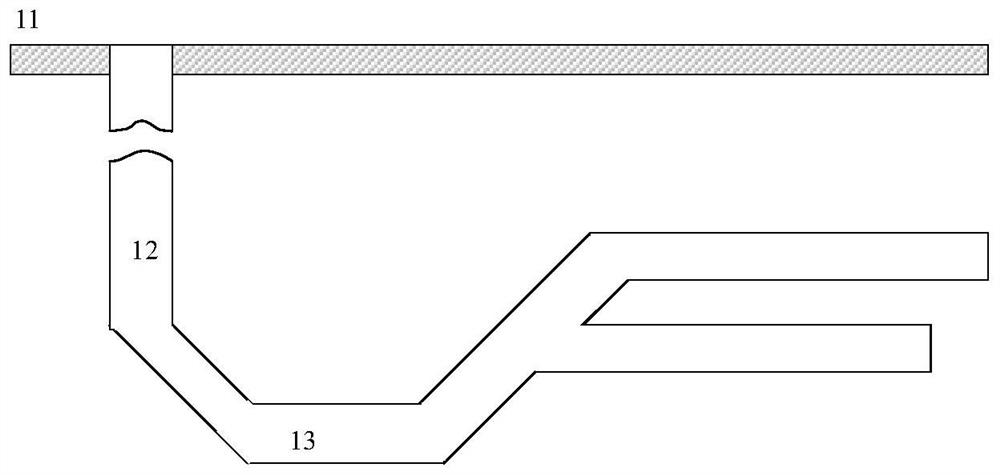

[0036] combine figure 1 , a schematic diagram of a coal mine structure used by a composite pumped storage system. The basic structure includes a ground 11, a coal mine shaft 12 and a coal mine roadway 13; the coal mine roadway 13 varies in altitude.

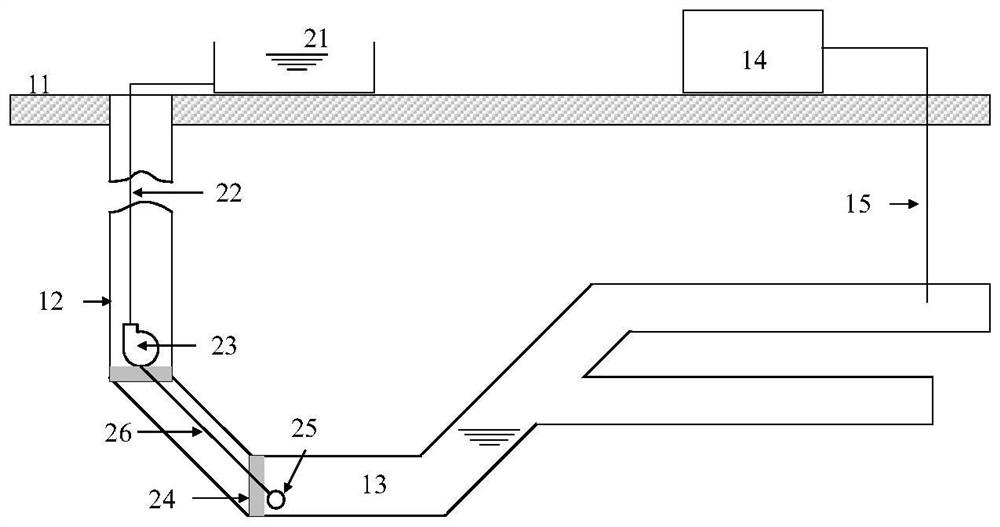

[0037] combine figure 2 , a composite pumped storage system includes a pumped storage module and a pressure regulation storage module 14 for adjusting the back pressure of the pump and turbine; the pumped storage module is composed of a ground reservoir 21 to form an upper reservoir, and a sluice wall 24 The sealed coal mine roadway 13 forms a lower reservoir, and an upper pipeline 22, a water pump turbine 23, a lower pipeline 26 and a filter 25 are arranged between the upper reservoir and the lower reservoir to connect in sequence; the connection point between the pressure regulating energy storage module 14 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com