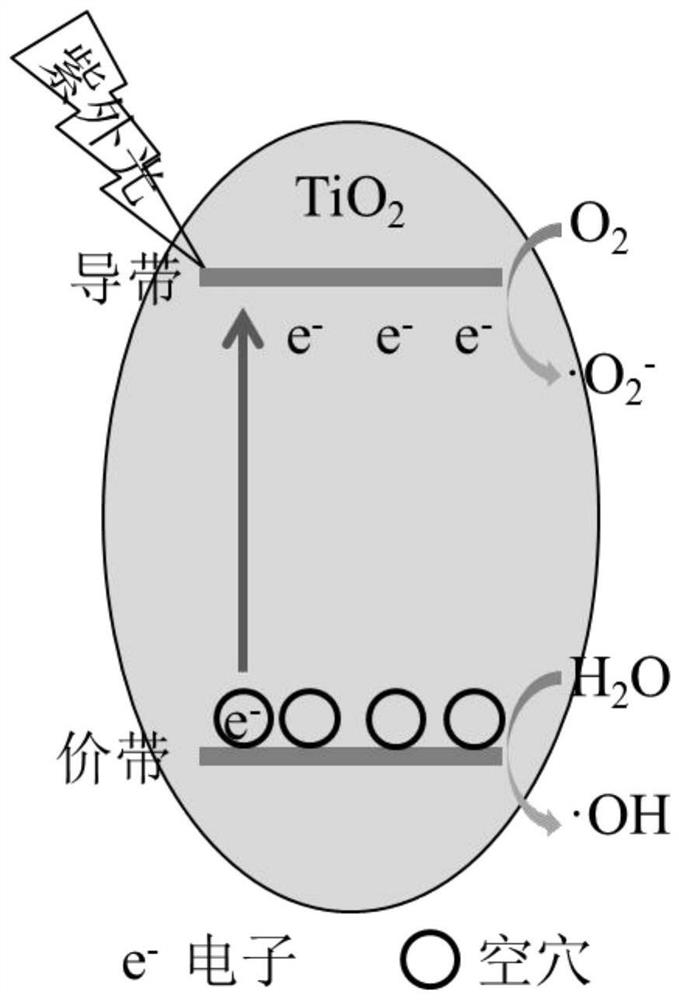

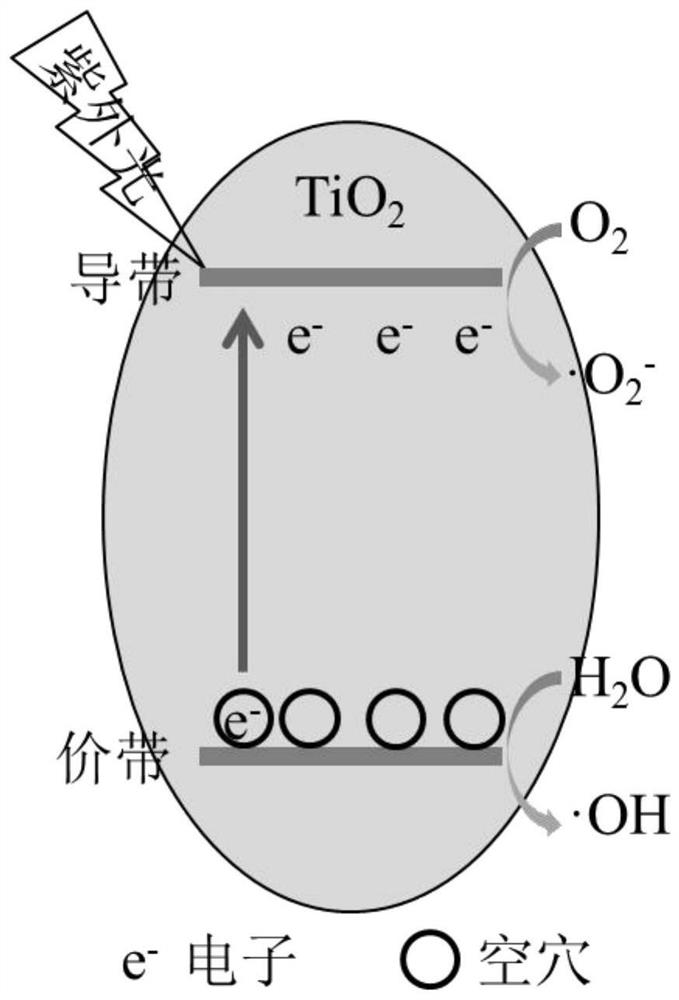

Photocatalysis-assisted tungsten chemical mechanical polishing composition and polishing method

A polishing composition and chemical-mechanical technology, applied in polishing compositions containing abrasives, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as process impact, decomposition failure, wafer scrap, etc., to improve the polishing rate. , the effect of reducing pollution and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Chelating agent: ethylenediaminetetraacetic acid.

[0031] Surfactant: stearic acid.

[0032] Abrasive: colloidal titanium dioxide: 10%, particle size of titanium dioxide particles: 90nm.

[0033] pH regulator: HNO3

[0034] pH=3

[0035] The composition and weight percentage of the polishing composition are as follows: colloidal titanium dioxide: 10%; chelating agent: 0.1%; surfactant: 0.1%; pH regulator: 0.1%; biocide: 0.1%.

[0036] Corresponding experimental data: polishing conditions: rotating speed of upper and lower throwing heads: 97 / 101rpm; flow rate of polishing composition: 200ml / min; polishing pressure: 1.5psi; power of ultraviolet lamp: 18W. Tungsten removal rate: Depression degree:

Embodiment 2

[0038] The composition and weight percentage of the polishing composition are as follows: colloidal titanium dioxide: 12.5%; chelating agent: 1%; surfactant: 0.1%; pH regulator: 1%; biocide: 1%.

[0039] Corresponding experimental data: polishing conditions: rotating speed of upper and lower throwing heads: 97 / 101rpm; flow rate of polishing composition: 200ml / min; polishing pressure: 1.5psi; power of ultraviolet lamp: 18W. Tungsten removal rate: Depression degree:

Embodiment 3

[0041] The composition and weight percentage of the polishing composition are as follows: colloidal titanium dioxide: 15%; chelating agent: 6%; surfactant: 1%; pH regulator: 2%; biocide: 2%.

[0042] Corresponding experimental data: polishing conditions: rotating speed of upper and lower throwing heads: 97 / 101rpm; flow rate of polishing composition: 200ml / min; polishing pressure: 1.5psi; power of ultraviolet lamp: 18W. Tungsten removal rate: Depression degree:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com