Fuel cell system and shutdown purging method thereof

A fuel cell system and electric stack technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of inability to effectively purge humidifiers and stack membranes, and achieve thermal purge, Extend the service life and avoid the effect of high potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

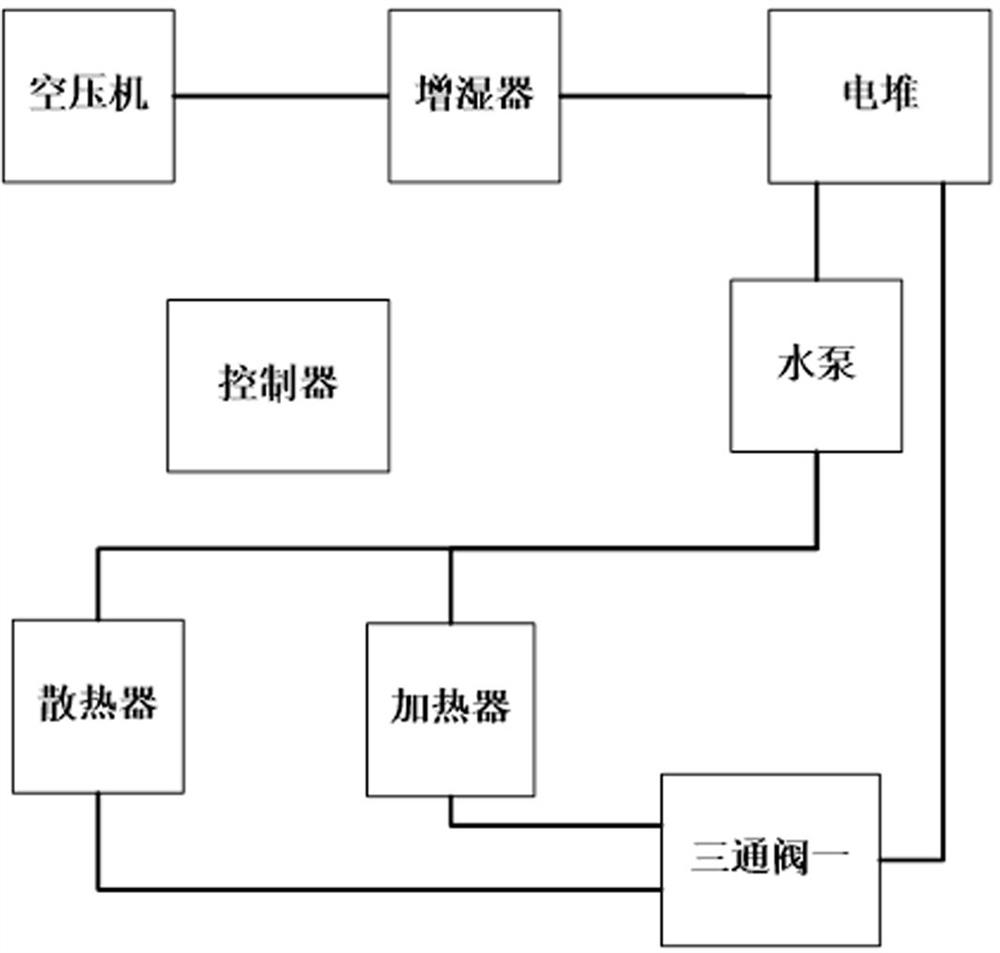

[0063] One embodiment of the present invention discloses a fuel cell system, such as figure 1 As shown, including electric stack, air compressor, water pump, heater, radiator, humidifier, three-way valve one and controller.

[0064] Among them, the air inlet of the stack is connected to the output end of the air compressor through the humidifier, the coolant inlet is connected to the output end of the three-way valve one, the coolant outlet is connected to the inlet of the water pump; the outlet of the water pump is connected to the three-way valve through the heater. The input end one of the through valve one is connected, and is connected with the input end two of the three-way valve one through the radiator.

[0065] The controller is used to control the first input end of the three-way valve one to be turned on and the second input end to be closed after receiving the shutdown command, to start the water pump and the heater until the temperature of the coolant inlet water ...

Embodiment 2

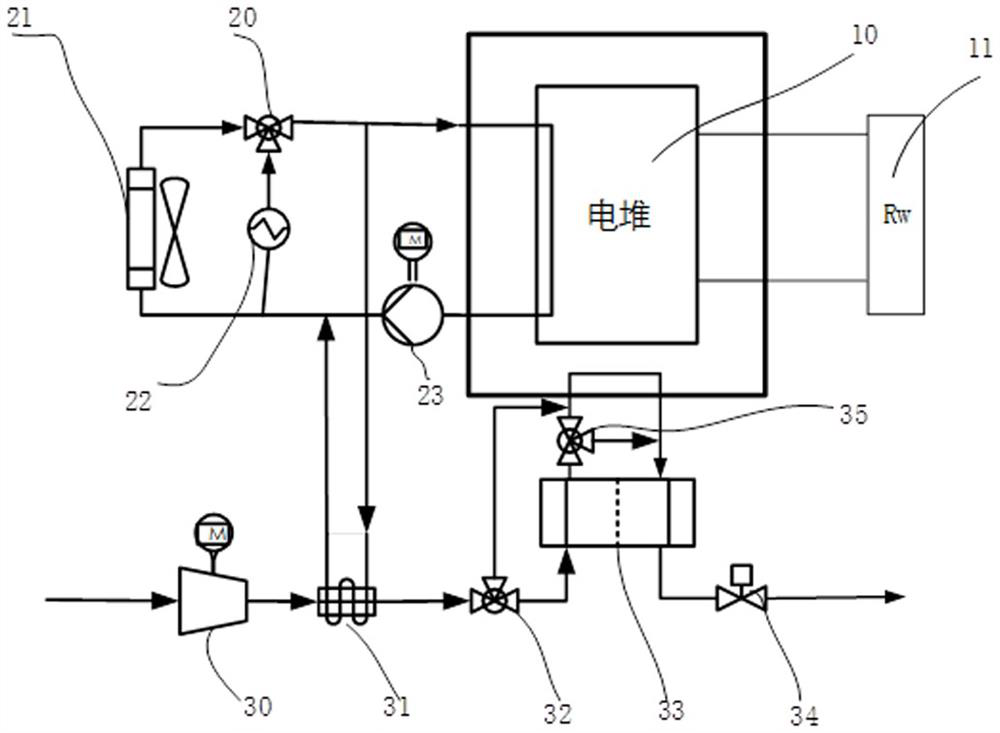

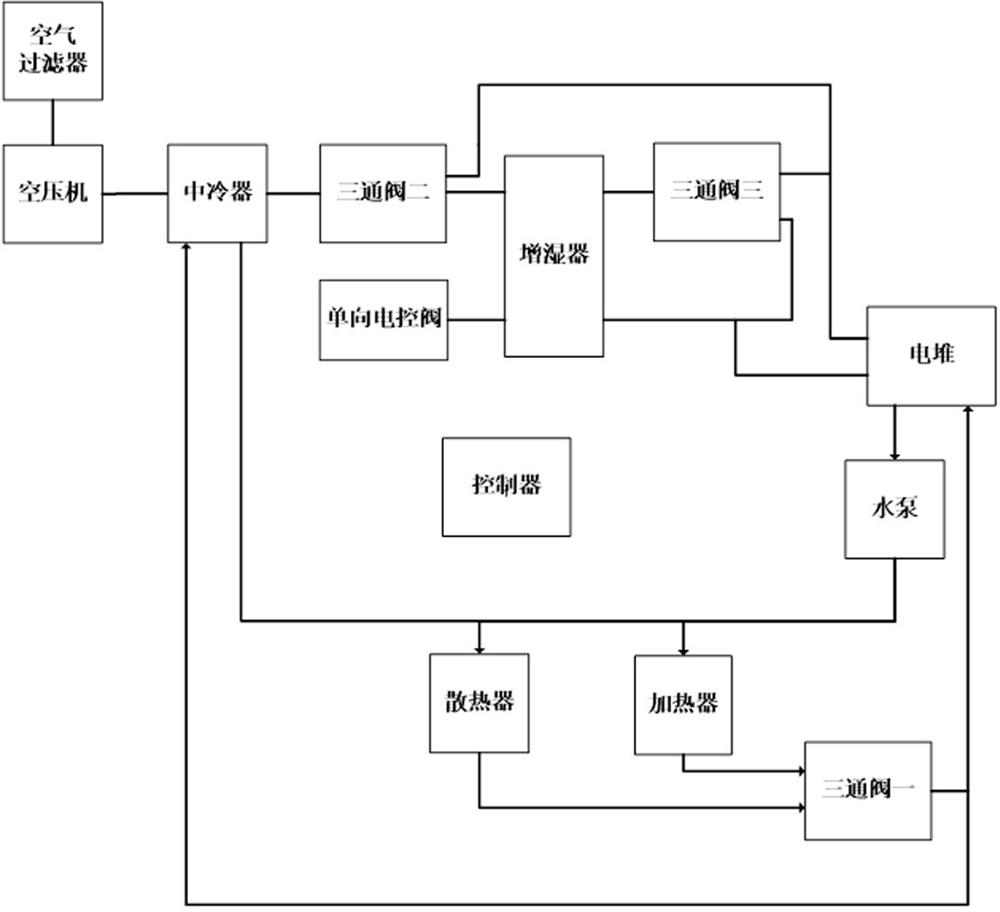

[0069] To improve on the basis of Example 1, the fuel cell system also includes a three-way valve two, such as Figure 2~3 shown.

[0070] Wherein, the input end of the electronically controlled three-way valve two is connected to the output end of the air compressor, the output end one is connected to the air inlet of the humidifier, the output end two is connected to the air inlet of the stack, and the control end is connected to the controller output connection.

[0071] Preferably, an air filter is provided at the front end of the air compressor to filter impurities such as dust and particles in the air, which is beneficial to improve the service life of the stack.

[0072] Preferably, the heater can be a PTC heater. The heater has the advantages of small size, high thermal efficiency, stable performance, strong adaptability, and low failure rate.

[0073] Preferably, the fuel cell system further includes an intercooler.

[0074] Wherein, the air inlet of the intercool...

Embodiment 3

[0109] Another embodiment of the present invention discloses a method for shutting down and purging the fuel cell system described in Embodiment 1 or 2, comprising the following steps:

[0110] S1. After receiving the shutdown command, control the input terminal 1 of the three-way valve 1 to open and the input terminal 2 to close;

[0111] S2. Start the water pump and heater until the temperature of the coolant inlet water of the stack rises to the threshold, and then turn off the heater;

[0112] S3. Control the air compressor to perform thermal purge on the stack and humidifier;

[0113] S4. After the purge is completed, the input terminal 1 of the control three-way valve 1 is closed, the input terminal 2 is opened, and the radiator is started until the water temperature at the inlet of the coolant drops to a set value, and the fuel cell system is shut down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com