Pharmaceutical composition for relieving oxidative stress injury and protecting nerves, preparation method and application

A technology for protecting nerves and oxidative stress, applied in drug combinations, pharmaceutical formulations, nervous system diseases, etc., can solve the problems of low absorption rate of natural ingredients stigmasterol, low intake of stigmasterol, and limited effect, etc., to relieve the brain Oxidative stress damage, immunity improvement, nerve protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

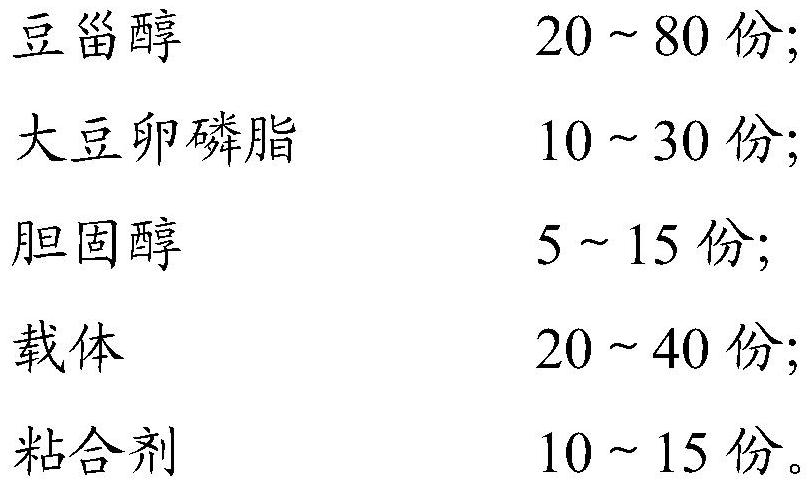

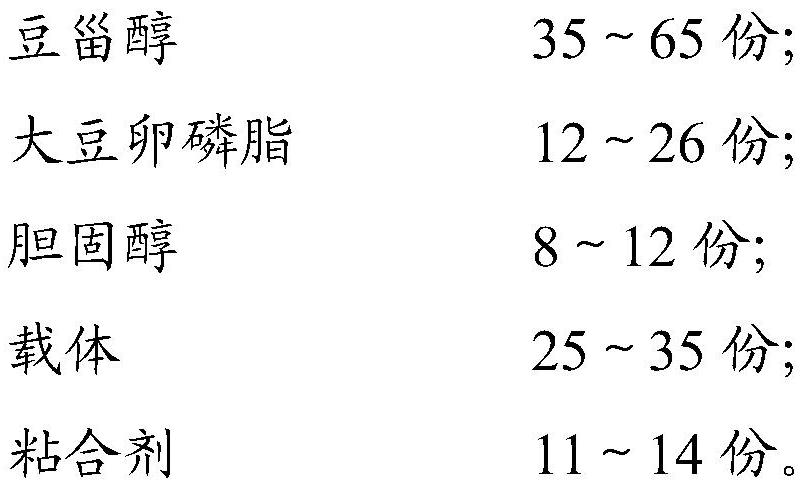

[0078] Embodiment 1: the preparation of pharmaceutical composition of the present invention

[0079] The implementation steps of this embodiment are as follows:

[0080] A. Wet granulation

[0081] 60 parts by weight of stigmasterol with a purity of 95.2% by weight, 16 parts by weight of soybean lecithin, 12 parts by weight of cholesterol, 34 parts by weight of yam powder carrier with a particle size of 40 to 80 and 12 parts by weight of hydroxypropyl methylcellulose Add the binder composed of microcrystalline cellulose according to the weight ratio of 1:9 to the HLSG-600 wet granulator sold by China Aviation Manufacturing Technology Research Institute, and stir under the conditions of cutting knife speed 2000rpm and stirring speed 120rpm Mix for 8min to obtain a stigmasterol mixture;

[0082] B. Extrude and roll

[0083] Let the stigmasterol mixture obtained in step A be extruded by the GYJ-500 type extrusion spheronizer sold by Chuangzhi Technology (Jiangsu) Co., Ltd. und...

Embodiment 2

[0086] Embodiment 2: the preparation of pharmaceutical composition of the present invention

[0087] The implementation steps of this embodiment are as follows:

[0088] A. Wet granulation

[0089] 80 parts by weight of stigmasterol with a purity of 96.0% by weight, 23 parts by weight of soybean lecithin, 15 parts by weight of cholesterol, 40 parts by weight of amylose carrier with a particle size of 40 to 80 mesh and 14 parts by weight of hydroxypropyl methylcellulose Add the binder composed of vegan and microcrystalline cellulose according to the weight ratio of 1:6 to the HLSG-100 wet granulator sold by Zhejiang Tomorrow Machinery Co., Ltd., and stir under the condition of cutting knife speed 1800rpm and stirring speed 100rpm Mix for 10min to obtain a stigmasterol mixture;

[0090] B. Extrude and roll

[0091] Let the stigmasterol mixture obtained in step A be extruded through the E-100 extruder+S-700 spheronizer sold by Chongqing Yingge Pharmaceutical Machinery Co., Ltd...

Embodiment 3

[0094] Embodiment 3: the preparation of pharmaceutical composition of the present invention

[0095] The implementation steps of this embodiment are as follows:

[0096] A. Wet granulation

[0097] 20 parts by weight of stigmasterol with a purity of 95.8% by weight, 10 parts by weight of soybean lecithin, 5 parts by weight of cholesterol, 20 parts by weight of a maltodextrin carrier with a particle size of 40 to 80 and 10 parts by weight of hydroxypropyl methylcellulose The binder composed of cellulose and microcrystalline cellulose according to the weight ratio of 1:8 is added to the HLSG-600 wet granulator sold by China Aviation Manufacturing Technology Research Institute, under the conditions of cutting knife speed 1500rpm and stirring speed 150rpm Stir and mix for 5min to obtain a stigmasterol mixture;

[0098] B. Extrude and roll

[0099] Let the stigmasterol mixture obtained in step A be extruded through the E-100 extruder+S-700 spheronizer sold by Chongqing Yingge Ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com