Method for producing gluconic acid by intensifying fermentation of glucose via penicillium funiculosum

A technology of Penicillium funicillium and gluconic acid, which is applied in the field of microbial fermentation, can solve the problems of strong inhibition of final products, low fermentation efficiency, and difficulty in increasing the control of culture conditions, so as to improve yield, expand germplasm resources, and realize self-defense Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

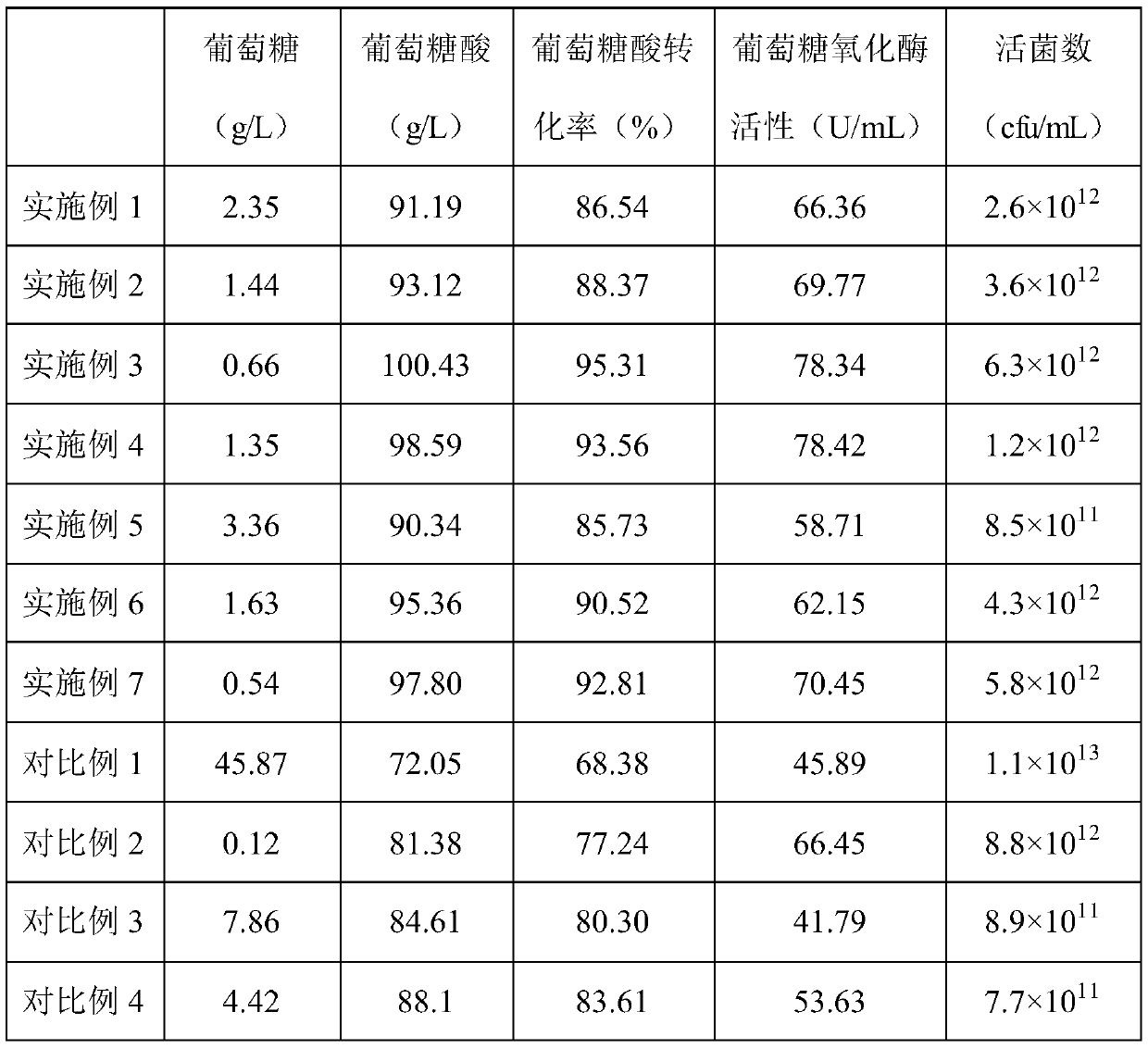

Examples

Embodiment 1

[0028] A method for strengthening penicillium fungus to ferment glucose to produce gluconic acid, comprising the following steps:

[0029] S1. Preparation of seed solution: pick the purified Penicillium fungus slant to the beef extract peptone medium, and cultivate it at 30°C and 180rpm for 20h. The bacteria are in the middle of the logarithmic growth phase at this time, with high activity and suitable for fermentation culture. , and then centrifuged to remove the supernatant (seed medium) to prevent the seed medium from interfering with the nutrient content of the fermentation medium, then wash the thalline pellet with sterile saline for 2 to 3 times and then resuspend the thalline to obtain the seed liquid. The concentration of the seed liquid is 1~5×10 9 cfu / mL;

[0030] S2. Fermentation: Inoculate the seed liquid into the fermentation medium according to the inoculation amount of 6%, and cultivate it to the bacterial concentration OD under the conditions of pH 6-8, temper...

Embodiment 2

[0033] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0034] S2. Fermentation: Inoculate the seed liquid into the fermentation medium according to the inoculation amount of 6%, and cultivate it to the bacterial concentration OD under the conditions of pH 6-8, temperature 37°C, and rotation speed 230rpm 600nm 2.0 to 2.5, then supplemented with 80g / L glucose and 0.2g / L inducer menadione, and fermented and cultivated for 72 hours under the conditions of pH 6-8, temperature 15°C, and rotation speed 330rpm to obtain gluconic acid.

Embodiment 3

[0036] Embodiment 3 is basically the same as Embodiment 1, and its difference is:

[0037] S2. Fermentation: Inoculate the seed liquid into the fermentation medium according to the inoculation amount of 6%, and cultivate it to the bacterial concentration OD under the conditions of pH 6-8, temperature 37°C, and rotation speed 230rpm 600nm 2.0 to 2.5, then supplemented with 100g / L glucose and 0.2g / L inducer menadione, and fermented and cultivated for 72 hours under the conditions of pH 6-8, temperature 15°C, and rotation speed 330rpm to obtain gluconic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com