Ultrasonic frequency pulse auxiliary electric arc welding method for dissimilar steel in underwater wet environment

A wet environment, underwater environment technology, applied in dissimilar steel ultrasonic frequency pulse assisted FCAW or SMAW (manual arc welding, arc welding, manual arc welding field, can solve the problem of low diffusible hydrogen content, to reduce diffusible hydrogen content, Important practical application value and the effect of ensuring safe development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

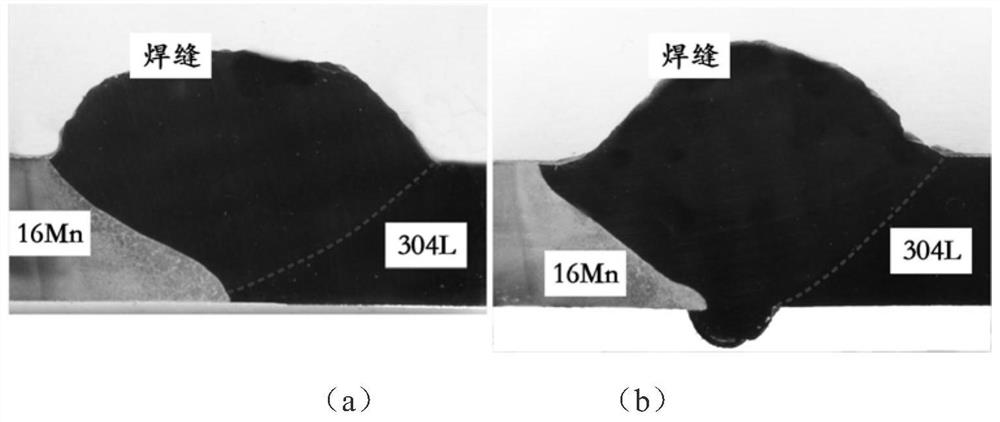

[0020] Such as Figure 1-2 shown.

[0021] A method for ultrasonic pulse-assisted arc welding of dissimilar steels in an underwater wet environment. The base metals used are low-alloy steel and austenitic stainless steel with a thickness of 8mm. The welding method is FCAW or SMAW welding technology, and the welding current For ultrasonic frequency pulse current, described welding comprises the following steps:

[0022] Step (1) Prepare before welding, clean and derust the low-alloy steel / austenitic stainless steel dissimilar steel plate, and wire-cut a 60° V-shaped groove at the place to be welded, leaving a 2mm blunt edge, and the welding material is water Under the special nickel-based self-shielding flux-cored wire.

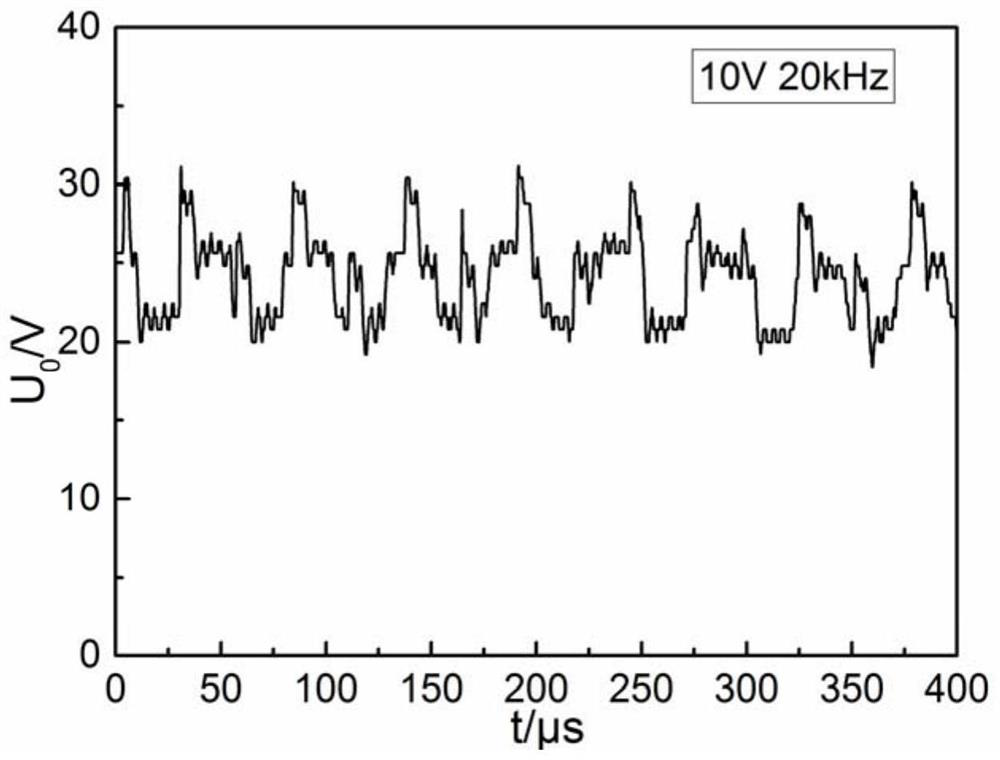

[0023] Step (2) Set the welding parameters, the welding current is 200A, the voltage is 30V, the output current of the ultrasonic frequency power supply is 45A, the power is 4kW, and the pulse frequency is 30kHz.

[0024] During specific implementation, the...

Embodiment 2

[0026] A method for assisting SMAW arc welding of dissimilar steels in an underwater wet environment by ultrasonic frequency pulses, the base metal used is low alloy steel and austenitic stainless steel, the thickness is 6mm, the welding method is SMAW welding technology, and the welding current is Ultrasonic frequency pulse current, described welding comprises the following steps:

[0027] Step (1) Prepare before welding, clean and derust the low-alloy steel / austenitic stainless steel dissimilar steel plate, and wire-cut a 45° V-shaped groove at the place to be welded, leaving a 1mm blunt edge, and the welding material is water The next special austenitic stainless steel electrode.

[0028] Step (2) Set welding parameters, welding current 160A, voltage 25V, dry elongation 10mm, ultrasonic frequency excitation source current 35A, power 6kW, pulse frequency 35kHz.

[0029] During specific implementation, the welding power source used can be directly customized from the market....

Embodiment 3

[0035] The difference between this embodiment and Embodiments 1 and 2 is that the V-shaped groove of 45° or 50° is processed by wire cutting at the place to be welded, leaving a blunt edge of 0.5mm or 1mm, and the welding material is a special nickel-based self-protecting flux core for underwater use. Welding wire / rod or stainless steel self shielded flux cored wire or rod.

[0036] Welding parameters, welding current 100A or 300A, arc voltage 24V or 40V, ultrasonic power supply output current 35A or 105A, power 4 kW or 7.5kW, pulse frequency 20kHz or 60 kHz.

[0037] All the other are identical with embodiment one, two, and weld seam cross section metallographic and figure 1 (b) Similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com